CNC sheet profiling spinning machine

A technology for spinning machines and thin plates, which is applied to metal processing machinery parts, driving devices, feeding devices, etc. It can solve problems such as damage and deformation, large force on roller components, and large force on roller tools, so as to improve effective efficiency, The effect of avoiding rapid wear and saving spinning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in further detail below in conjunction with the accompanying drawings.

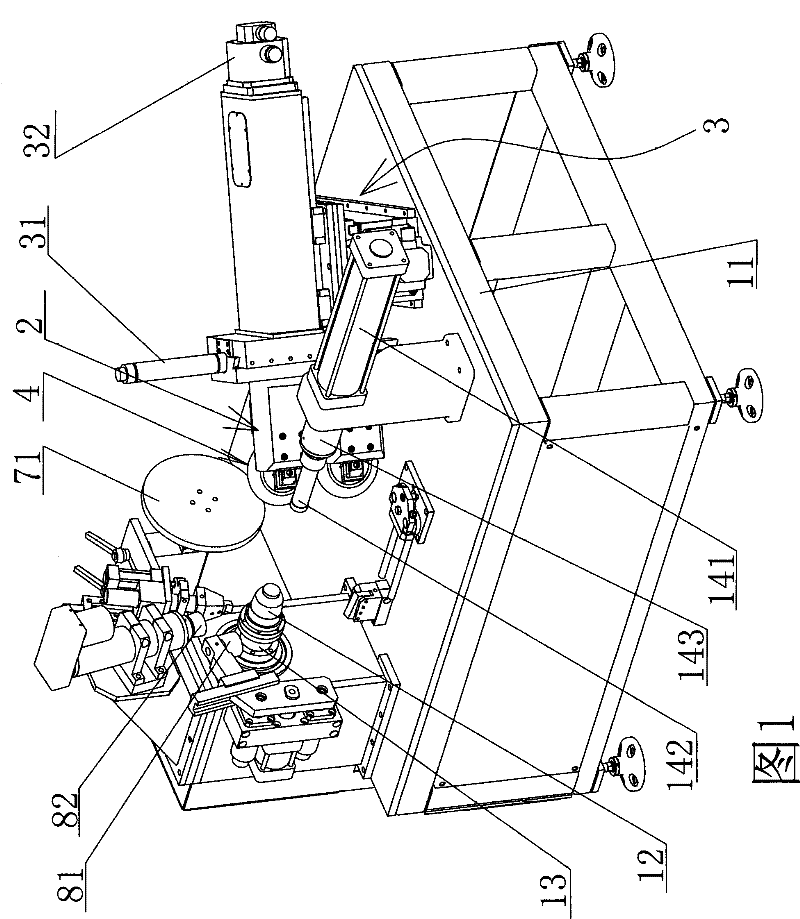

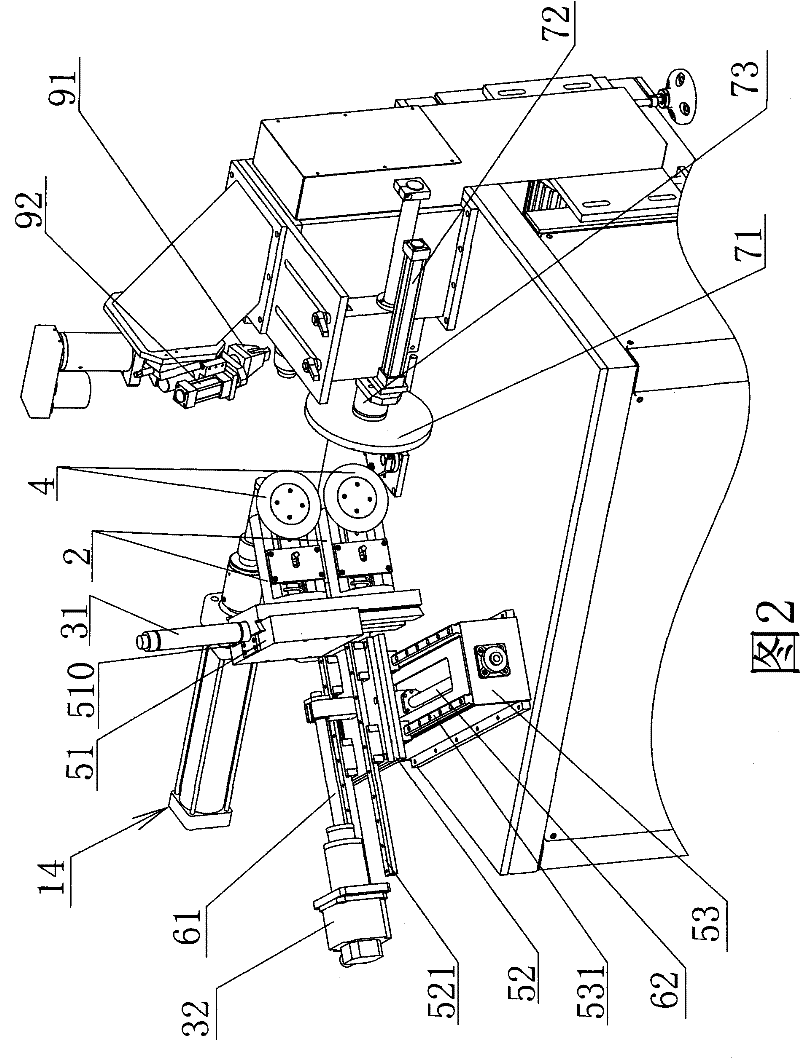

[0025] As shown in the figure, the CNC thin plate profiling spinning machine includes a frame 11, a main shaft 13 equipped with a round die base 12, a transmission mechanism for driving the main shaft 13 to rotate, and can clamp and position the metal sheet on the round die The thimble mechanism 14 on the seat 12, the spinning mechanism 2 used for spinning the thin plate, and the numerical control drive assembly 3 that drives the spinning mechanism 2 to move. The transmission mechanism is arranged in the headstock 18 provided on the frame 11 and driven by the motor.

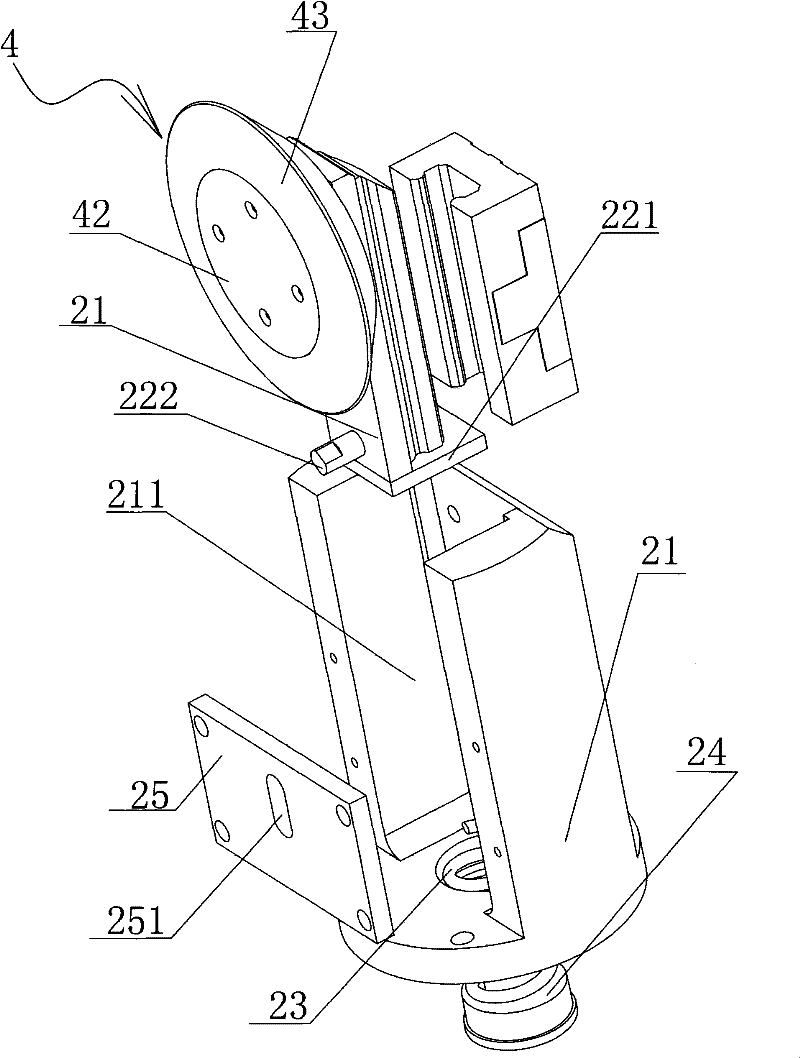

[0026] The spinning mechanism 2 includes a base body 21 and a slide plate 22 mounted on the base body 21 that can slide back and forth. The base body 21 is provided with a preload spring 23 for pushing the slide plate 22 outward. The slide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com