A self-adaptive weather-resistant electrical cabinet control and adjustment method

A technology for controlling and adjusting electrical cabinets, which is applied to electrical components, structural parts of electrical equipment, and modification using gaseous coolants, which can solve the problem of inability to self-adaptively adjust the temperature and humidity of electrical cabinets, and the failure of self-adaptive regulation of temperature and humidity in electrical cabinets and other issues to achieve the effect of reducing impact and increasing heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

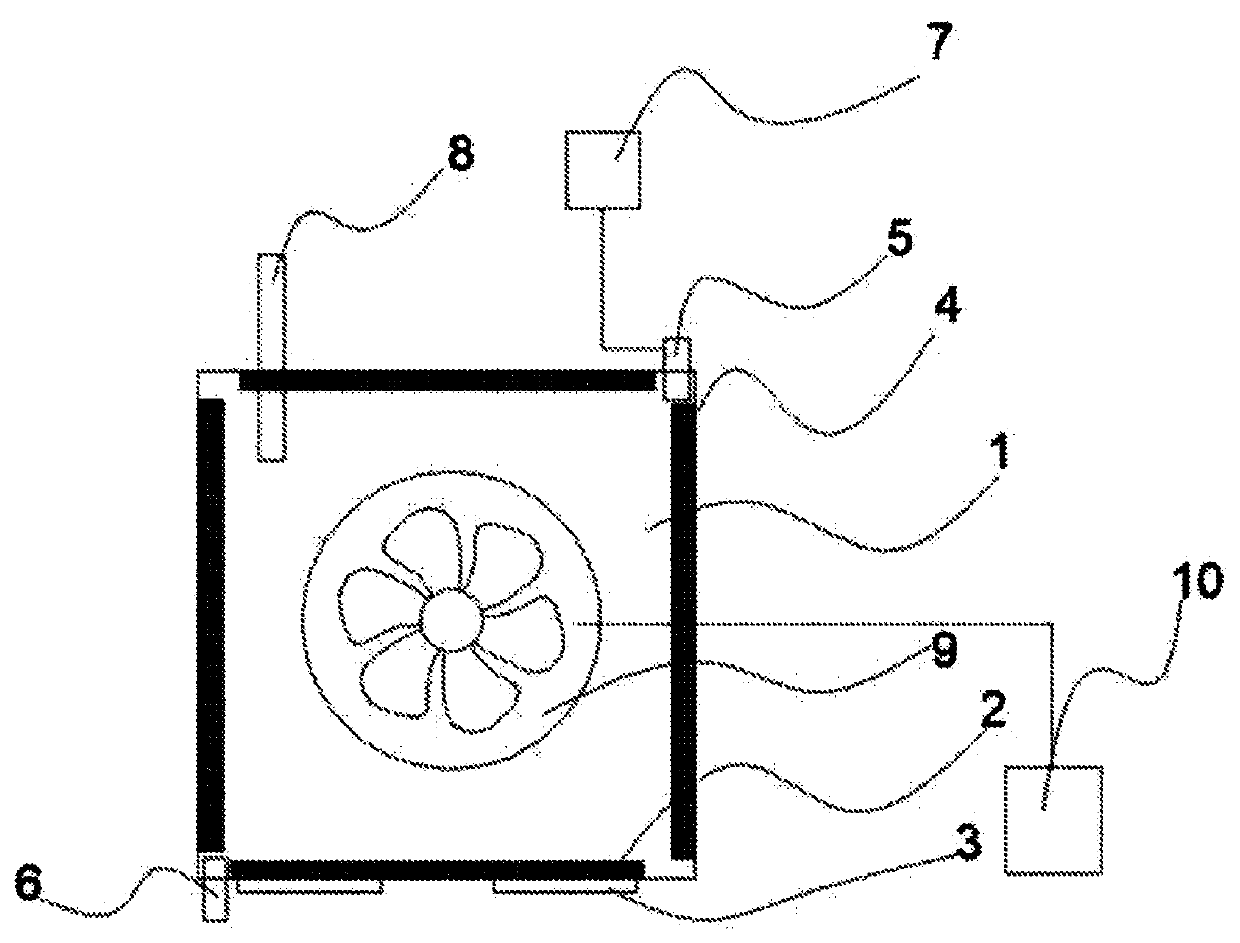

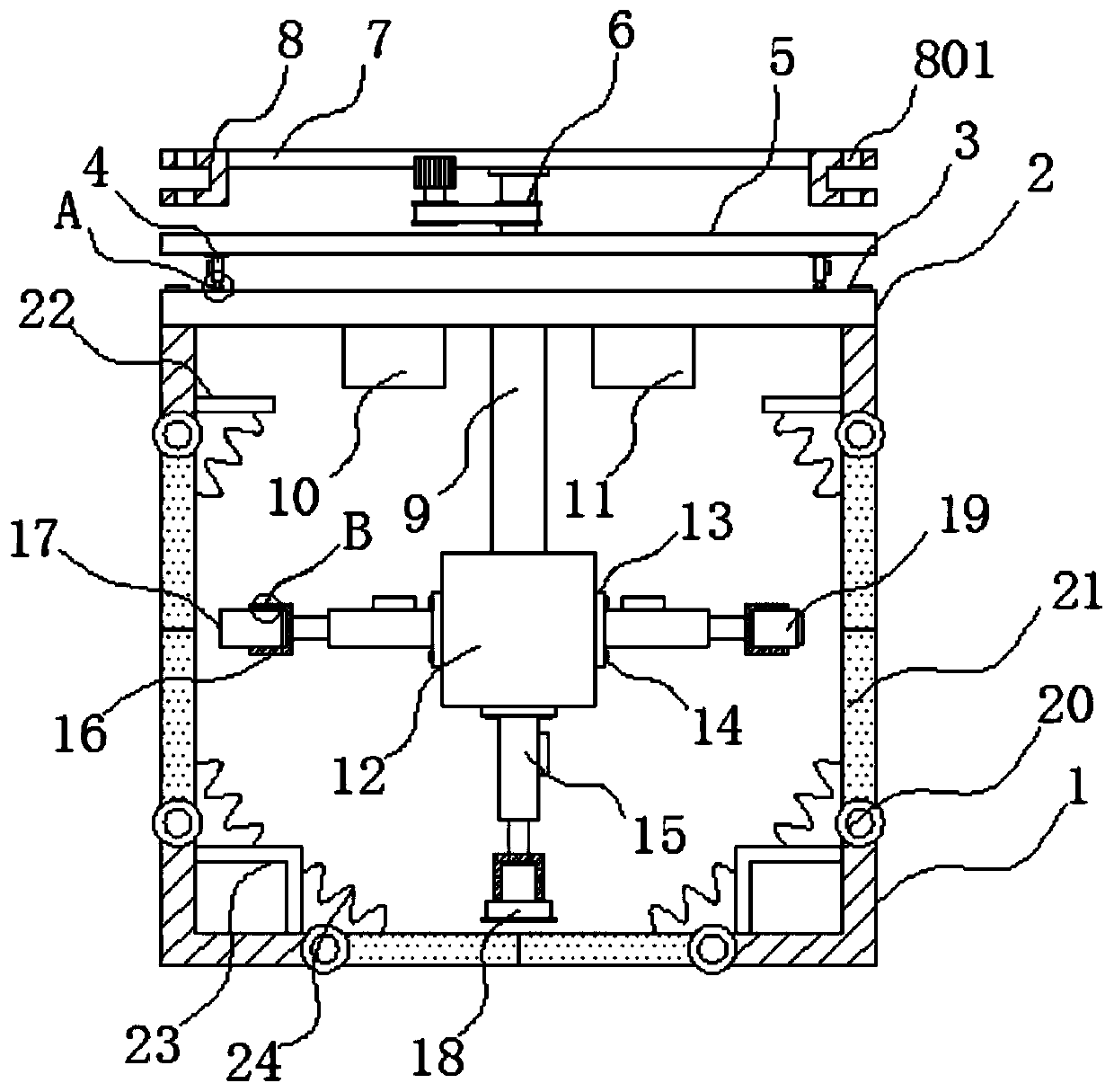

[0053] like Figure 8 As shown, an adaptive weather-resistant electrical cabinet control adjustment method, the control adjustment method includes the following steps:

[0054] A control and adjustment method for an adaptive weather-resistant electrical cabinet, the control and adjustment method comprising the following steps:

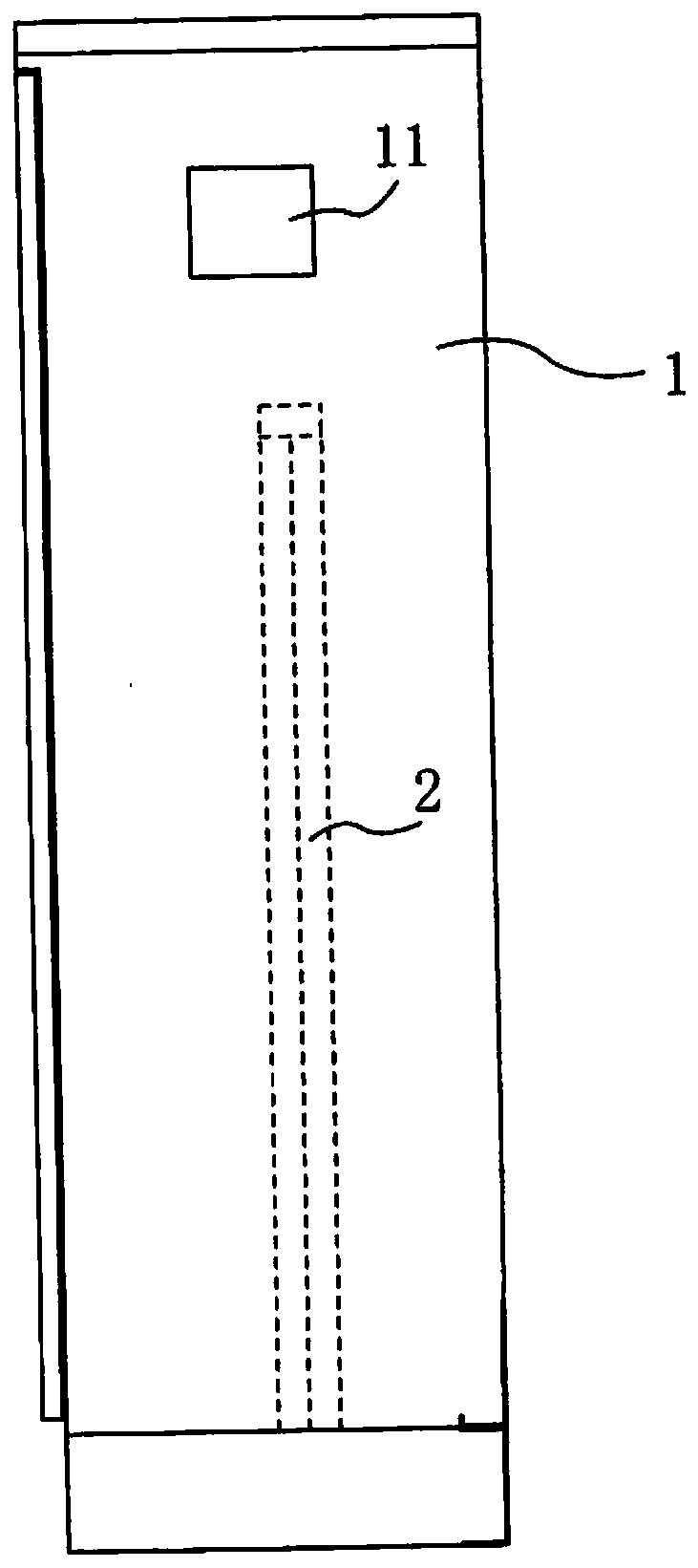

[0055] S1: Fix the control device of the electrical cabinet in the electrical cabinet with a connecting plate or a clamp structure, and adjust the orientation of the bottom box;

[0056] S2: The temperature and humidity in the electrical cabinet is sensed by the temperature and humidity sensor element inside the temperature and humidity controller. When the humidity is too high and exceeds the preset upper threshold B1, the electric heater on the clamp block is pushed to expand and contract by the second electric push rod Move, open the door of the box, and the electric heater will heat the inside of the electrical cabinet to remove the moisture;

[...

Embodiment 2

[0070] like Figure 8 As shown, an adaptive weather-resistant electrical cabinet control adjustment method, the control adjustment method includes the following steps:

[0071] A control and adjustment method for an adaptive weather-resistant electrical cabinet, the control and adjustment method comprising the following steps:

[0072] S1: Fix the control device of the electrical cabinet in the electrical cabinet with a connecting plate or a clamp structure, and adjust the orientation of the bottom box;

[0073] S2: The temperature and humidity in the electrical cabinet is sensed by the temperature and humidity sensor element inside the temperature and humidity controller. When the humidity is too high and exceeds the preset upper threshold B1, the electric heater on the clamp block is pushed to expand and contract by the second electric push rod Move, open the door of the box, and the electric heater will heat the inside of the electrical cabinet to remove the moisture;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com