Oviductus ranae soft capsule and manufacturing process thereof

A production process and technology of huskies oil, which is applied in the directions of capsule delivery, non-active ingredients of oil/fat/wax, and medical preparations containing active ingredients, etc. The loss of ingredients and other problems, to achieve the effect of preventing oxidation, low sterilization temperature, and high nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

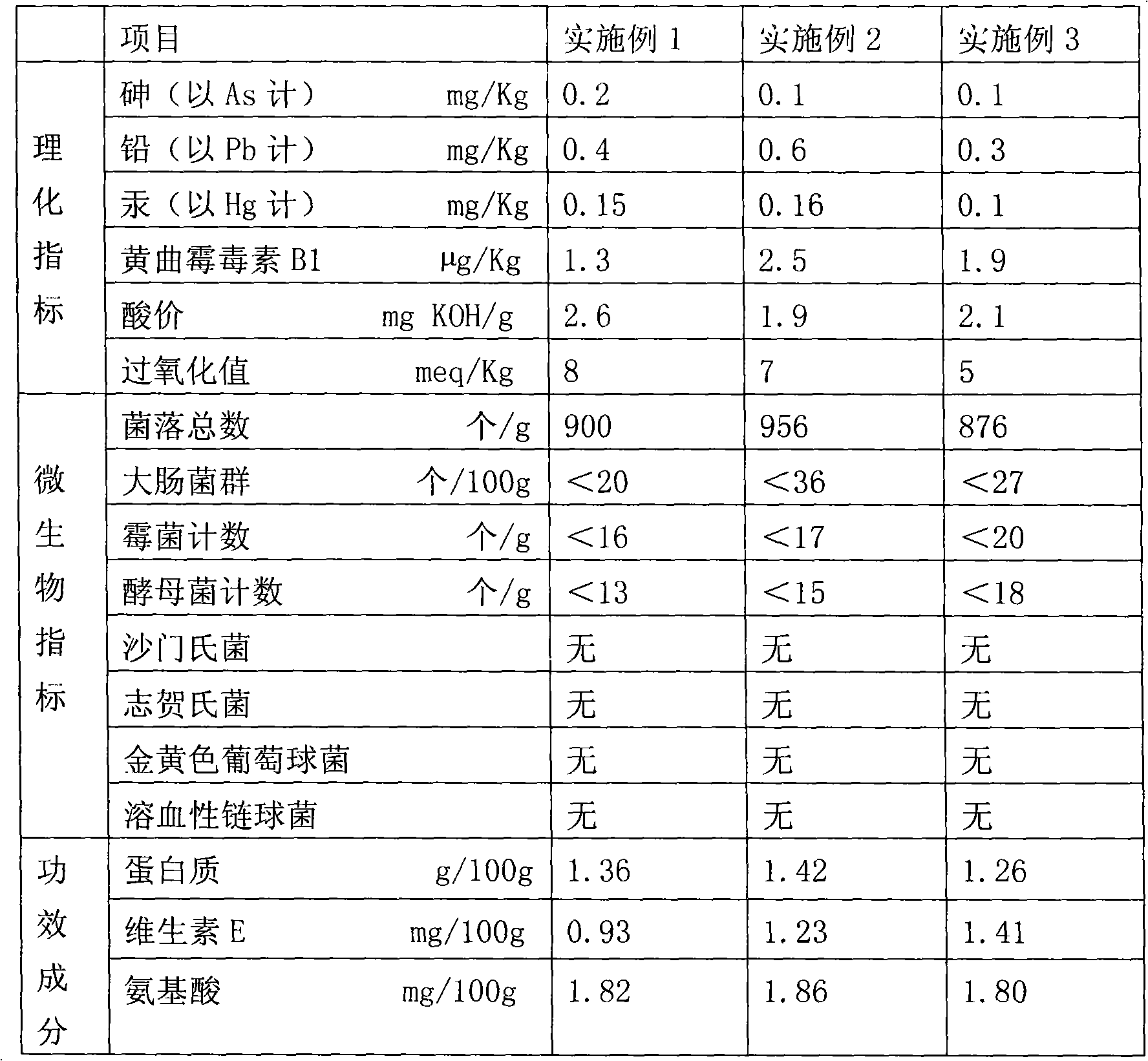

Examples

Embodiment 1

[0013] The toad oil soft capsule is prepared from the following raw materials in proportion by weight: 70 parts of processed toad oil, 29.5 parts of soybean salad oil, 0.5 part of vitamin E and 1.5 parts of glyceryl monostearate.

[0014] The manufacturing process includes the following steps:

[0015] 1) Preparation of active toad oil: take fresh toad oil, remove viscera, skin, meat, mud and eggs, wash, and dry; microwave sterilization at a temperature of 40°C for 2 to 3 minutes, send to put into a freeze dryer, and freeze for 8 hours at a temperature of -40°C; start the vacuum pump, and heat up for the first time at a vacuum of 5Pa, and heat and sublimate for 10 hours at 30°C; At 80°C, heat and sublimate for 12 hours; for the third time, at 80°C, heat and sublimate for 10 hours to obtain active haasia oil;

[0016] 2) hair preparation: add the active toad oil into sterile water 4 times its weight, and make hair at room temperature for 10 hours;

[0017] 3) Two-step cooling...

Embodiment 2

[0023] Hashi toad oil soft capsule is made of the following raw materials in proportion by weight: 60 parts of hair-made toad oil, 29 parts of soybean salad oil, 0.3 part of vitamin E and 1 part of glyceryl monostearate;

[0024] The manufacturing process includes the following steps:

[0025] 1) Preparation of active toad oil: take fresh toad oil, remove viscera, skin, meat, mud and eggs, wash, and dry; microwave sterilization at a temperature of 30°C for 2 to 3 minutes, send to put into a freeze dryer, and freeze for 9 hours at a temperature of -45°C; start the vacuum pump, and heat up for the first time at a vacuum of 1.3 PaPa, and heat and sublimate for 11 hours at 25°C; Heating and sublimation at 55°C for 13 hours; heating and sublimation for the third time at 75°C for 11 hours to obtain active haasia oil;

[0026] 2) hair preparation: add the active haasia oil to 4 times the weight of sterile water, and make it at room temperature for 8 hours;

[0027] 3) Two-step cool...

Embodiment 3

[0033] Hashi toad oil soft capsule is made of the following raw materials in proportion by weight: 60 parts of hair-made toad oil, 30 parts of soybean salad oil, 0.7 part of vitamin E and 2 parts of glyceryl monostearate;

[0034] The manufacturing process includes the following steps:

[0035] 1) Preparation of active toad oil: take fresh toad oil, remove viscera, skin, meat, mud and eggs, wash, and dry; microwave sterilization at a temperature of 50°C for 2 to 3 minutes, send to put into a freeze dryer, and freeze for 7 hours at a temperature of -35°C; start the vacuum pump, and in the state of a vacuum of 13Pa, heat up for the first time, and sublimate for 9 hours at 35°C; At 85°C, heat and sublimate for 11 hours; for the third time, at 85°C, heat and sublimate for 9 hours to obtain active haasia oil;

[0036] 2) hair preparation: add the active husky toad oil into sterilized water with 4 times its weight, and make hair at room temperature for 12 hours;

[0037] 3) Two-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com