Vertical rolling-compaction tester

A detection machine, vertical technology, applied in the direction of measuring device, measurement of the change force of the optical properties of the material when it is stressed, metal sawing equipment, etc., can solve the problem of not having detection function, etc., to reduce labor intensity , enhance durability, and eliminate internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

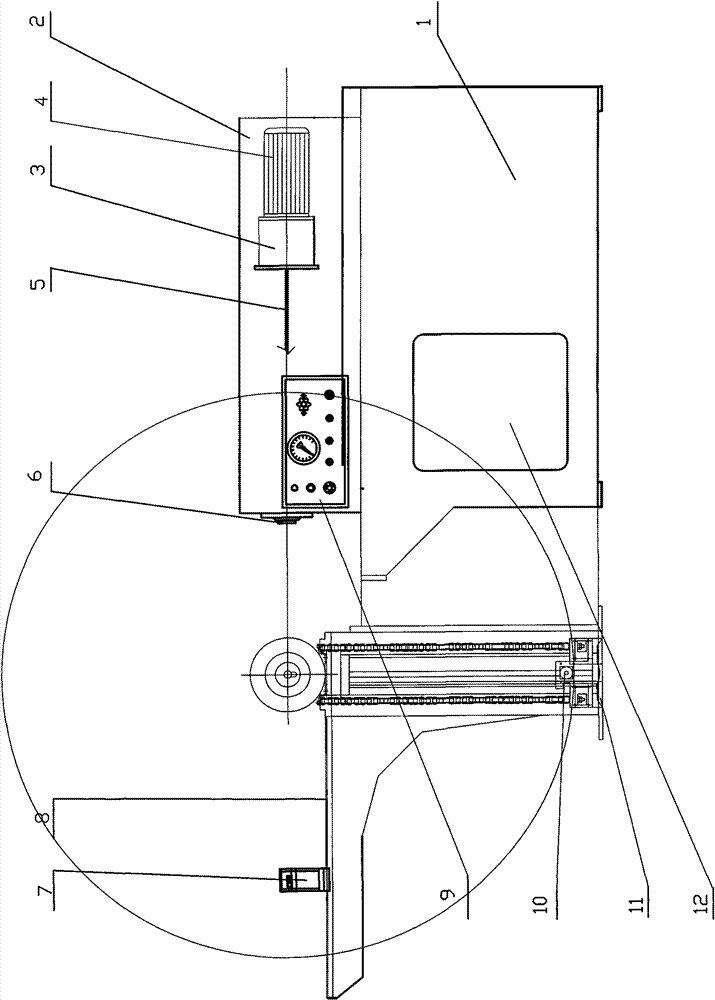

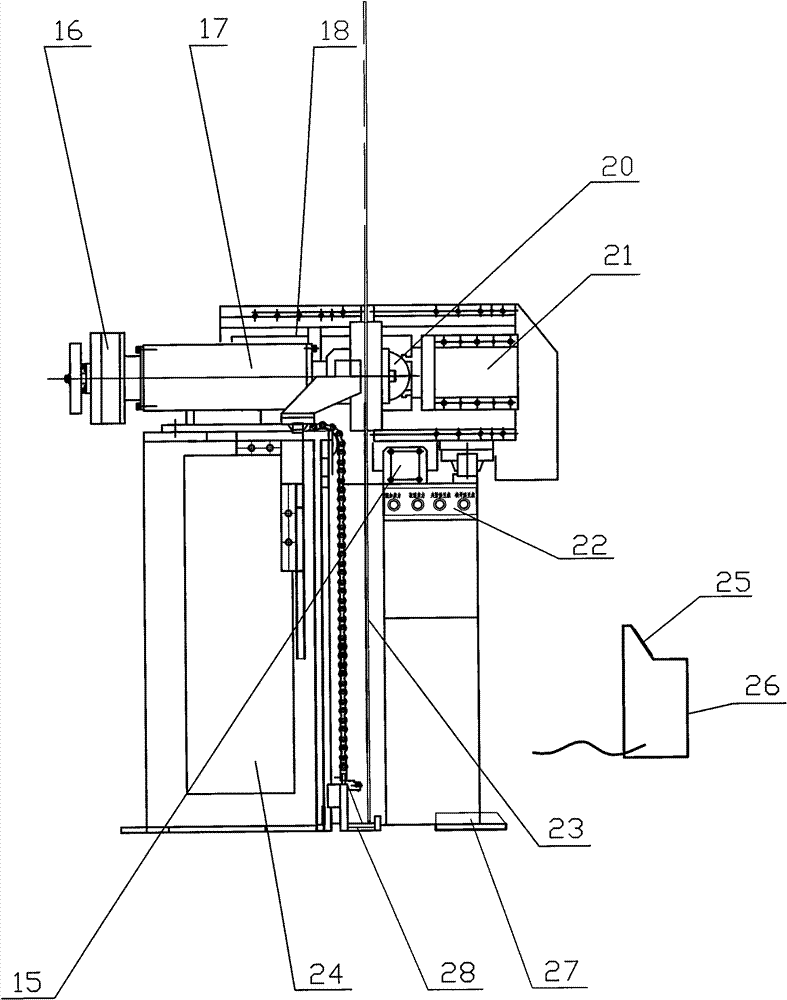

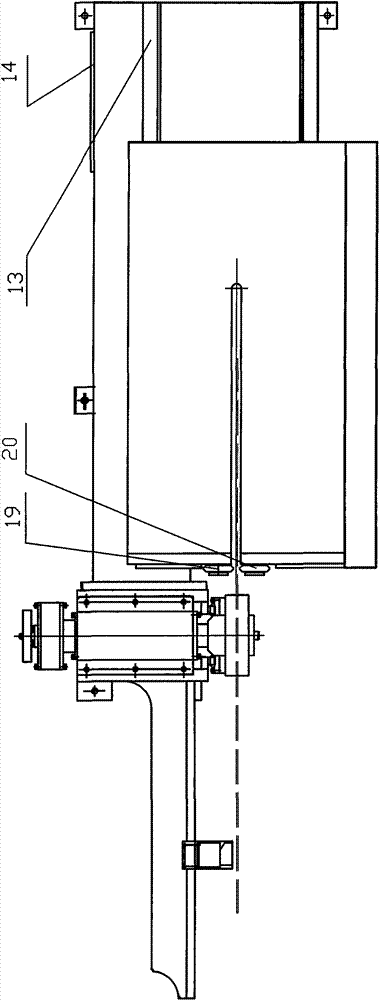

[0028] Such as figure 1 , figure 2 and image 3 As shown, a vertical rolling inspection machine,

[0029] The rolling head 2 is installed on the fuselage 1 through the rolling guide rail 13, and the rolling head oil cylinder 15 drives the rolling head 2 to run along the rolling guide rail 13;

[0030] The clamping device 17 is installed on the fuselage 1 on one side of the rolling head 2, the clamping device 17 is perpendicular to the rolling head 2, and the axis of the clamping device 17 is also parallel to the horizontal plane. After the workpiece 23 is clamped, the workpiece 23 and the The ground is vertical, and the clamping device 17 is provided with a clamping cylinder 16. The clamping cylinder 16 is connected with the pull rod in the shaft. After the workpiece 23 is installed, the movable flange is placed on the pull rod, and then a chuck is mounted on the outside to clamp After the tight cylinder 16 moves, the pull bar promptly drives the movable flange to clamp th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com