Chemical method for preparing three-dimensional dendritic copper selenide nano-crystalline photoelectric film material

A technology for optoelectronic thin films and thin film materials, applied in the field of material chemistry, can solve the problems of harsh conditions, high solvent toxicity, impure products, etc., and achieve high coverage, convenient operation, good light absorption and photoluminescence performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation: Put the analytically pure metal copper sheet into a beaker filled with dilute hydrochloric acid solution (concentrated hydrochloric acid and deionized water, volume ratio 1:20), clean it with an ultrasonic cleaner for 0.5 hours, and then soak it in absolute ethanol ready for use. Wash the polytetrafluoroethylene container successively with tap water, distilled water, and absolute ethanol, and dry it for use.

[0031] (2) Reaction steps: put the processed metal copper sheet into the polytetrafluoroethylene container, add n-hexanol solvent to the height of 80% of the container and add selenium powder simultaneously, the selenium powder concentration is 0.0007 g / ml, polytetrafluoroethylene The vinyl fluoride container was placed in a stainless steel jacket and placed in an oven with a temperature-programmed function at a rate of 2°C / min, and the temperature was raised to 190°C for 3 hours.

[0032] (3) Post-treatment: after the reaction, turn off the powe...

Embodiment 2

[0034] (1) preparatory work: with embodiment 1.

[0035] (2) Reaction steps: put the processed metal copper sheet into the polytetrafluoroethylene container, add cyclohexanol solvent to the height of 80% of the container and add selenium powder simultaneously, the selenium powder concentration is 0.0007 g / ml, polytetrafluoroethylene The tetrafluoroethylene container was placed in a stainless steel jacket and placed in an oven with a temperature-programmed function at a rate of 2°C / min, and the temperature was raised to 190°C for 3 hours.

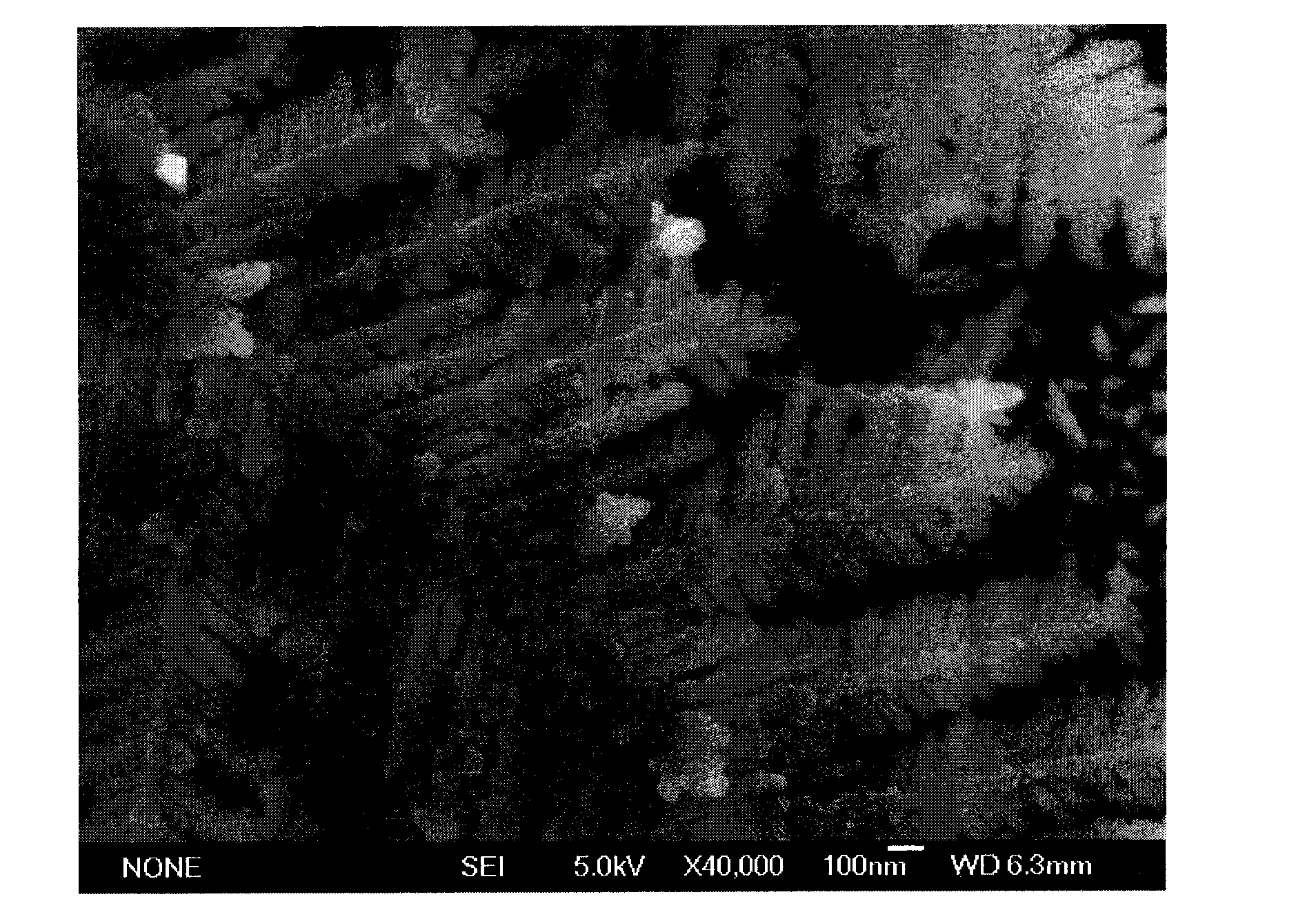

[0036] (3) Post-treatment: after the reaction, turn off the power of the oven and cool down to room temperature naturally. Wash the product with absolute ethanol for 5 times, put it into a vacuum drying oven and dry at 50°C for 5 hours to obtain a copper selenide film sample, and then carefully transfer it to a sample bottle and store it in a dark and dry environment. The color of the product is dark black, and the microstructure under the ...

Embodiment 3

[0038] (1) preparatory work: with embodiment 1.

[0039] (2) Reaction steps: put the processed metal copper sheet into the polytetrafluoroethylene container, add dehydrated alcohol solvent to the height of 80% of the container and add selenium powder simultaneously, the concentration of selenium powder is 0.0007 g / ml, polytetrafluoroethylene The tetrafluoroethylene container was placed in a stainless steel jacket and placed in an oven with a temperature-programmed function, and the temperature was raised to 200° C., and the reaction was carried out for 1 hour, and the heating rate was 2° C. / min.

[0040] (3) Post-treatment: after the reaction, turn off the power of the oven and cool down to room temperature naturally. Wash the product twice with absolute ethanol and put it into a vacuum drying oven at 50°C to dry for 4 hours to obtain a copper selenide film sample, then carefully transfer it to a sample bottle and store it in a dark and dry environment. The color of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com