Water-soluble conducting polyaniline static-free damping paint and preparation method thereof

A technology of conductive polyaniline and damping coatings, applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of poor anti-static damping coatings, achieve excellent shock absorption effect, and widen the damping temperature range , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

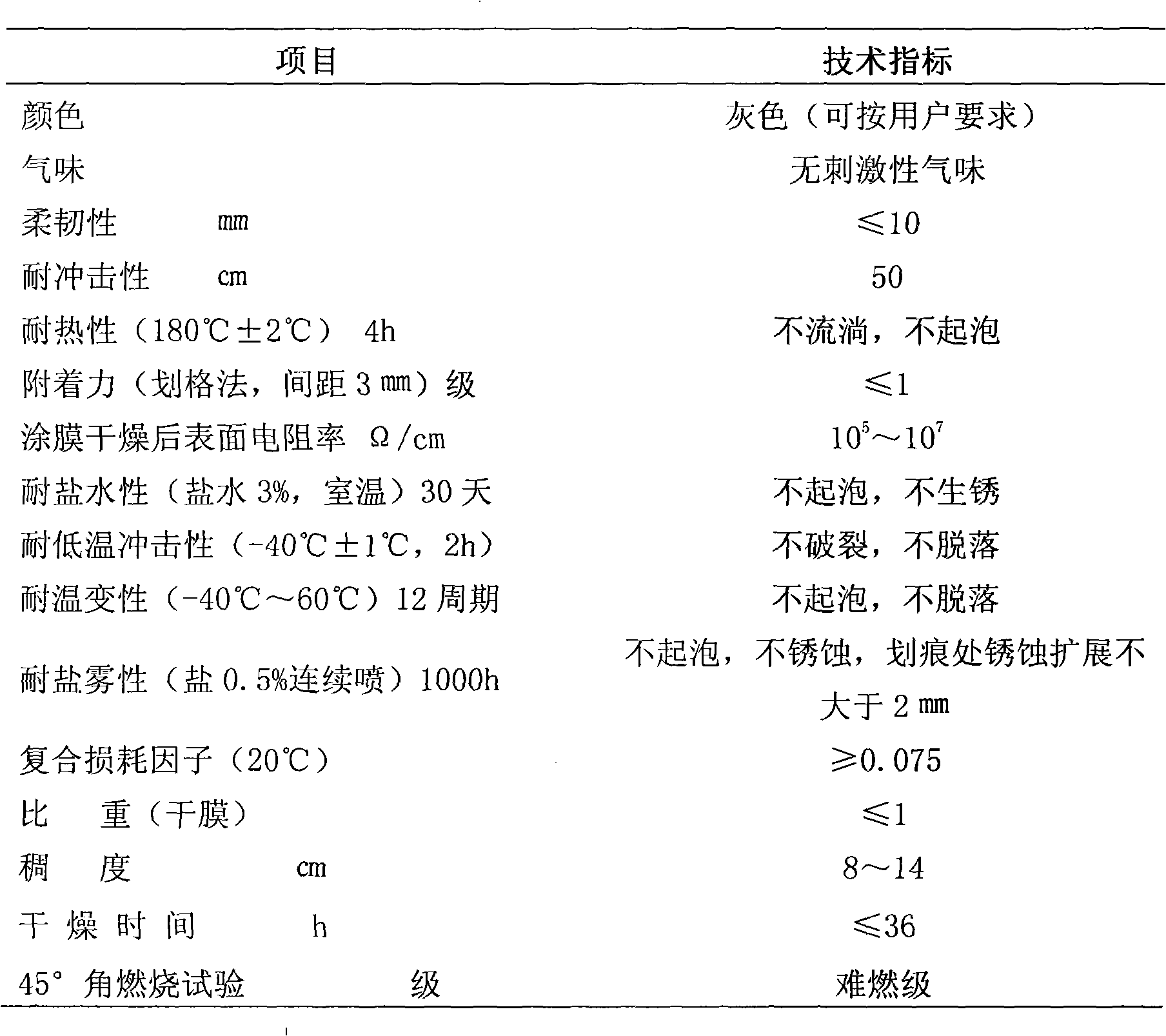

Method used

Image

Examples

Embodiment 1

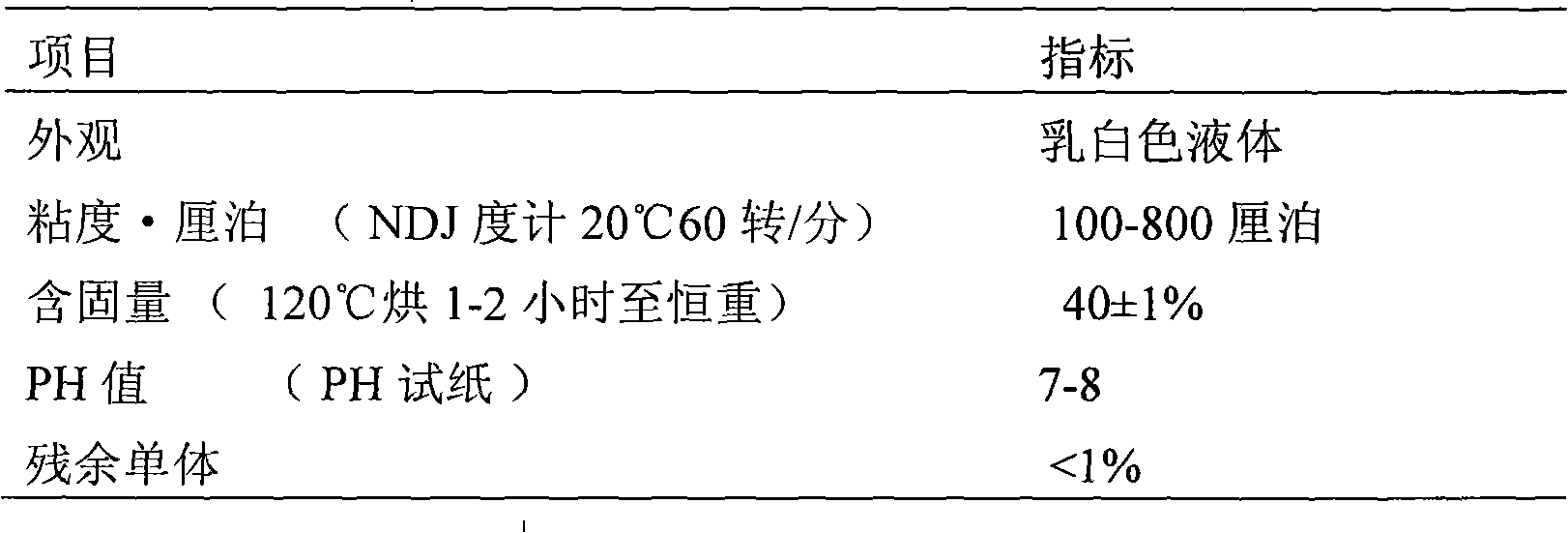

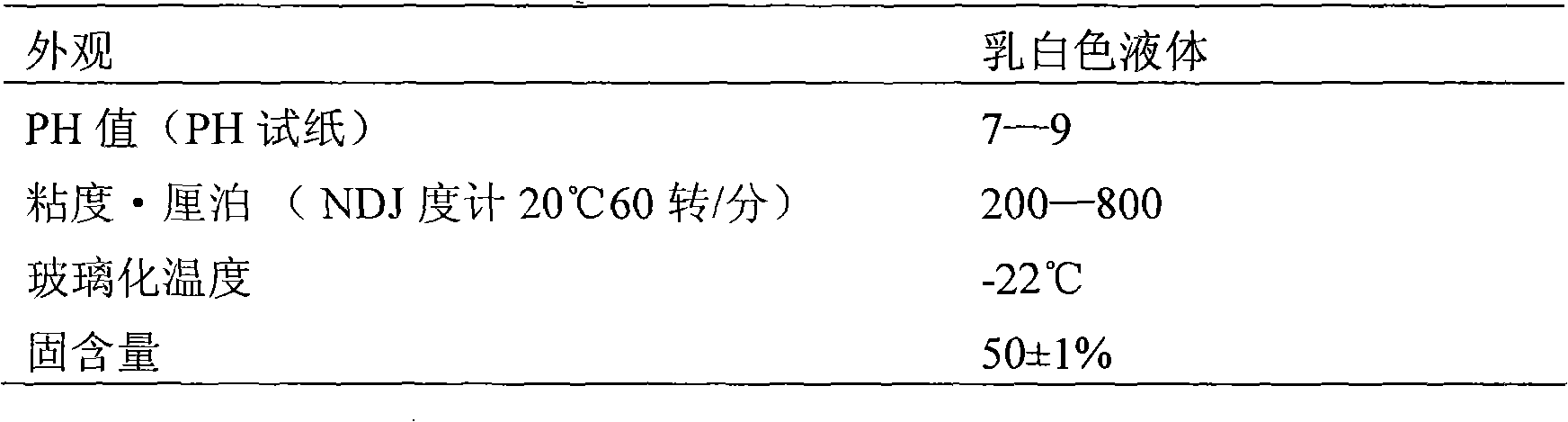

[0034] Add 35 grams of sulfuric acid and 5 grams of silver nitrate into a 100ml three-neck flask, stir and heat up to 80°C, slowly add 10g of intrinsic polyaniline, heat up to 90°C, stir at 60 rpm for 3 hours, and fill in 250ml In the stainless steel container, add 50 grams of water and stir with a high-speed mixer at 1200 rpm to make it all dissolve. An aqueous conductive polyaniline solution with a solid content of 7.5% was obtained.

[0035] Take 8 grams of styrene-acrylic emulsion for water-based damping coatings, 12 grams of water-based elastic pure acrylic emulsion; 18 grams of mica powder (80 mesh), 3.5 grams of zinc phosphate, 5.0 grams of talc, 3.5 grams of barium sulfate, 2.5 grams of light calcium, and 10 grams of silica sand 27.5 grams of water-based conductive polyaniline solution; 1.5 grams of dibutyl phthalate, 5 grams of propylene glycol, 4 grams of alcohol ester, 1.0 grams of superfine active magnesium hydroxide flame retardant, 0.06 grams of isothiazolinone b...

Embodiment 2

[0037] Add 20 grams of sulfuric acid and 5 grams of silver nitrate into a 100ml three-neck flask, stir and heat up to 80°C, slowly add 15g of intrinsic polyaniline, heat up to 90°C, stir at 70 rpm for 3 hours, and put it into a 250ml stainless steel container , add 60 grams of water and stir with a high-speed mixer at 1200 rpm to make it all dissolve. An aqueous conductive polyaniline solution with a solid content of 8.2% was obtained.

[0038] Take 15 grams of styrene-acrylic emulsion for water-based damping coatings, 15 grams of water-based elastic pure acrylic emulsion; 15.4 grams of 80 mesh mica powder, 2.8 grams of zinc phosphate, 3.5 grams of talcum powder, 2.8 grams of barium sulfate, 2.1 grams of titanium dioxide, and 8.4 grams of silica sand; 20 grams of water-soluble conductive polyaniline solution; 3 grams of dibutyl phthalate, 3 grams of propylene glycol, 6 grams of ester alcohol, 3 grams of superfine active magnesium hydroxide flame retardant, 0.13 grams of isothi...

Embodiment 3

[0040] Add 50 grams of sulfuric acid and 3 grams of silver nitrate into a 100ml three-neck flask, stir and heat up to 80°C, slowly add 12g of intrinsic polyaniline, heat up to 90°C, stir at 80 rpm for 3 hours, and put it into a 250ml stainless steel container , add 35 grams of water and stir with a high-speed mixer at 1200 rpm to make it all dissolve to obtain a water-soluble conductive polyaniline solution with a solid content of 7.8%.

[0041] Take 24 grams of water-based damping paint styrene-acrylic emulsion, 16 grams of water-based elastic pure acrylic emulsion; 17.6 grams of mica powder 80 mesh, 3.2 grams of zinc phosphate, 4.0 grams of talcum powder, 3.2 grams of barium sulfate, 2.4 grams of light calcium, 9.6 grams of silica sand; water-soluble 15 grams of conductive polyaniline solution; 1 gram of dibutyl phthalate, 1 gram of propylene glycol, 2 grams of ester alcohol, 5 grams of superfine active aluminum hydroxide flame retardant, and 0.2 grams of isothiazolinone bact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com