Method for preparing methane chloride by dimethyl sulfate

A technology of dimethyl sulfate and monochloromethane, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of low economic benefit, low concentration, influence on utilization, etc., and achieves remarkable economic benefits, Simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

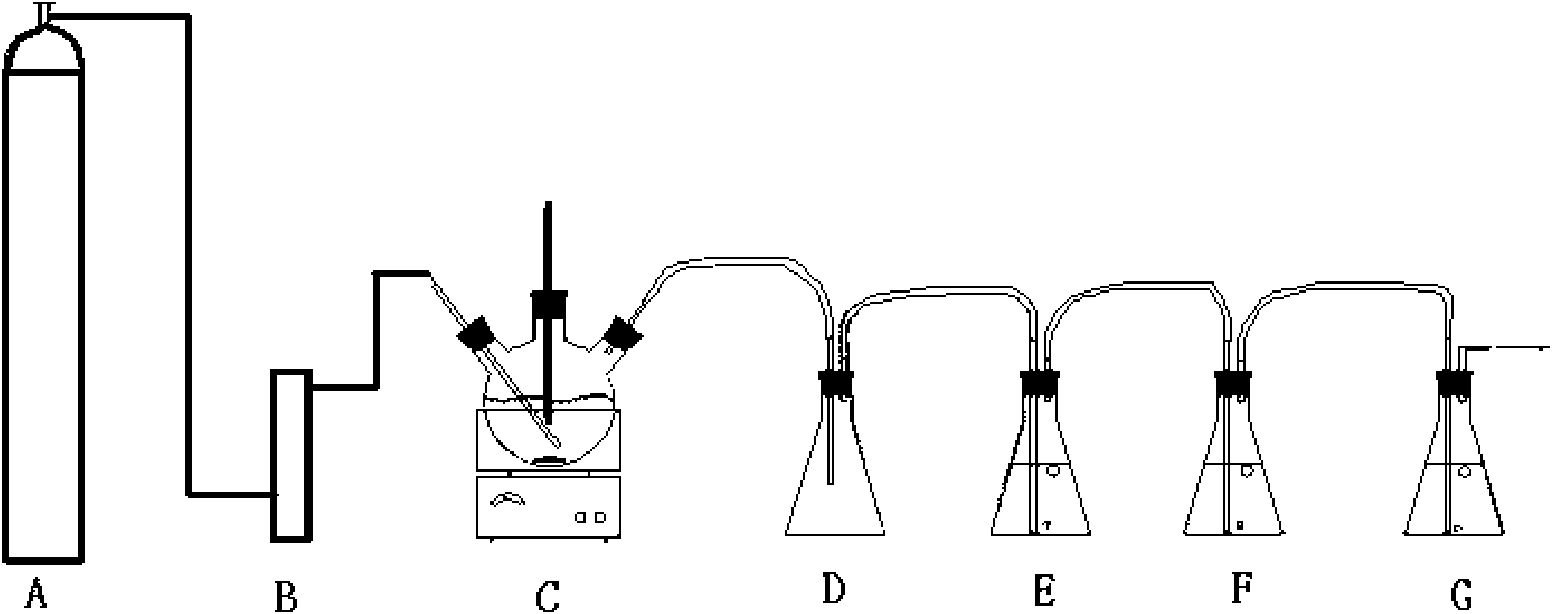

Image

Examples

Embodiment 1

[0017] Mix 1 mol of dimethyl sulfate with 98.3wt% concentrated sulfuric acid, and the ratio of dimethyl sulfate to sulfuric acid is 1:1. Put the mixture into a flask, heat it to 100°C, and then pass in hydrogen chloride gas to react for 8 hours. The generated gas is washed with water, washed with alkali, and dried to obtain the product gas. Wherein the rate of the hydrogen chloride that feeds is 1mol / h, and the used lye of alkali washing is the sodium hydroxide solution of 5wt%.

[0018] The generated gas was detected, and the conversion rate of dimethyl sulfate was calculated to be 54.6%, the yield of monochloromethane was 54.6%, and the purity of monochloromethane was 99.1%.

Embodiment 2

[0020] Mix 0.5mol dimethyl sulfate with 95wt% concentrated sulfuric acid, the ratio of dimethyl sulfate to sulfuric acid is 1:1. Put the mixture into a three-necked flask, heat it to 120°C, and then pass in hydrogen chloride gas to react for 10 hours. The generated gas is washed with water, washed with alkali, and dried to obtain the product gas. Wherein the rate of the hydrogen chloride that feeds is 1mol / h, and the lye used for alkali washing is 10wt% sodium hydroxide solution.

[0021] The generated gas was detected, and the conversion rate of dimethyl sulfate was calculated to be 76.7%, the yield of monochloromethane was 76.7%, and the purity of monochloromethane was 99.4%.

Embodiment 3

[0023] Put 0.8 mol of dimethyl sulfate into a three-necked flask, heat it to 60°C, and inject hydrogen chloride gas to react for 0.5 h. The generated gas is washed with water, washed with alkali, and dried to obtain product gas. Wherein the rate of the hydrogen chloride that feeds is 8mol / h, and the used lye of alkali washing is the sodium hydroxide solution of 15wt%.

[0024] The generated gas was detected, and the conversion ratio of dimethyl sulfate was calculated to be 32.3%, the yield of monochloromethane was 32.3%, and the purity of monochloromethane was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com