Metal plating method for carbon nanotubes

A metal coating and carbon nanotube technology, applied in the field of metal coating, can solve the problem of uneven distribution of the coating, and achieve the effects of large field enhancement factor, increased current density, and easy release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

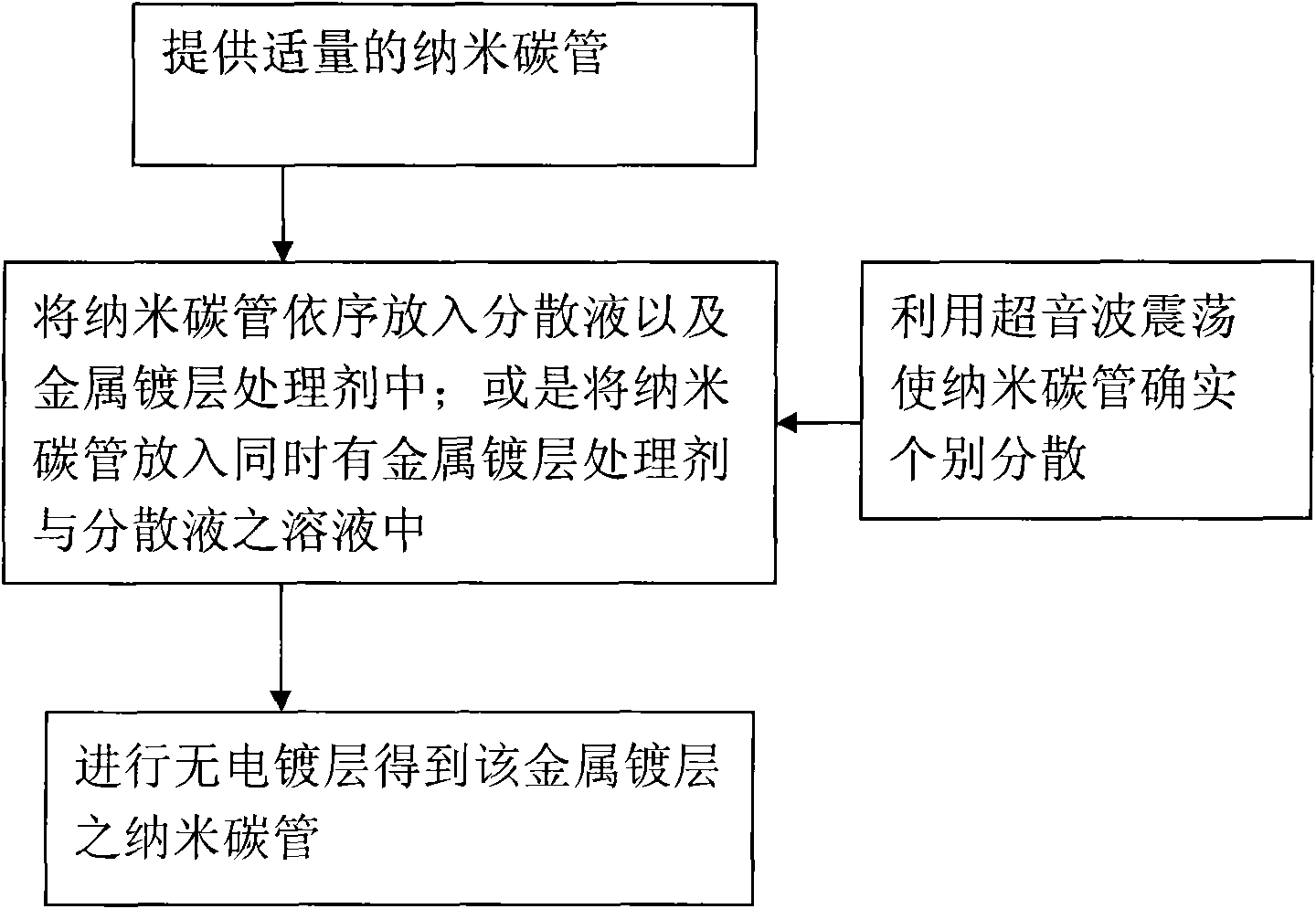

[0014] Please refer to Figure 3 to Figure 5 As shown, the process and results of the metal coating method for carbon nanotubes of the present invention, wherein one embodiment of the present invention is to first take carbon nanotubes 30 of appropriate length on the utensil, put the carbon nanotubes 30 into an alcohol solution, and use super Take it out after oscillating with sound waves for three seconds, wash with ultrasonic waves in water for three seconds, and repeat the cleaning step three times. The composition of each step chemical solution adopted in this embodiment and the operating conditions of coordination are as follows:

[0015] Operating conditions:

[0016] (1) Sodium hydroxide (NaOH), water (H 2 O) and alcohols (C n h 2n+1 OH) mixed solution (preferably containing 5-30% alcohol solution), 80°C;

[0017] (2) Sulfuric acid (H 2 SO 4 ), water (H 2 O) and alcohols (C n h 2n+1 OH) mixed solution (5-30% alcohol solution is better), room temperature;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com