Method for winding superconductive magnet

A winding method and technology for superconducting magnets, which are applied in the manufacture of superconducting magnets/coils, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of increasing winding complexity and uncertainty, complex structure, difficult cooling and protection and other issues, to achieve the effect of reducing the twisting force and the influence on the flow capacity, increasing the compactness of the structure, and reducing the difficulty of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

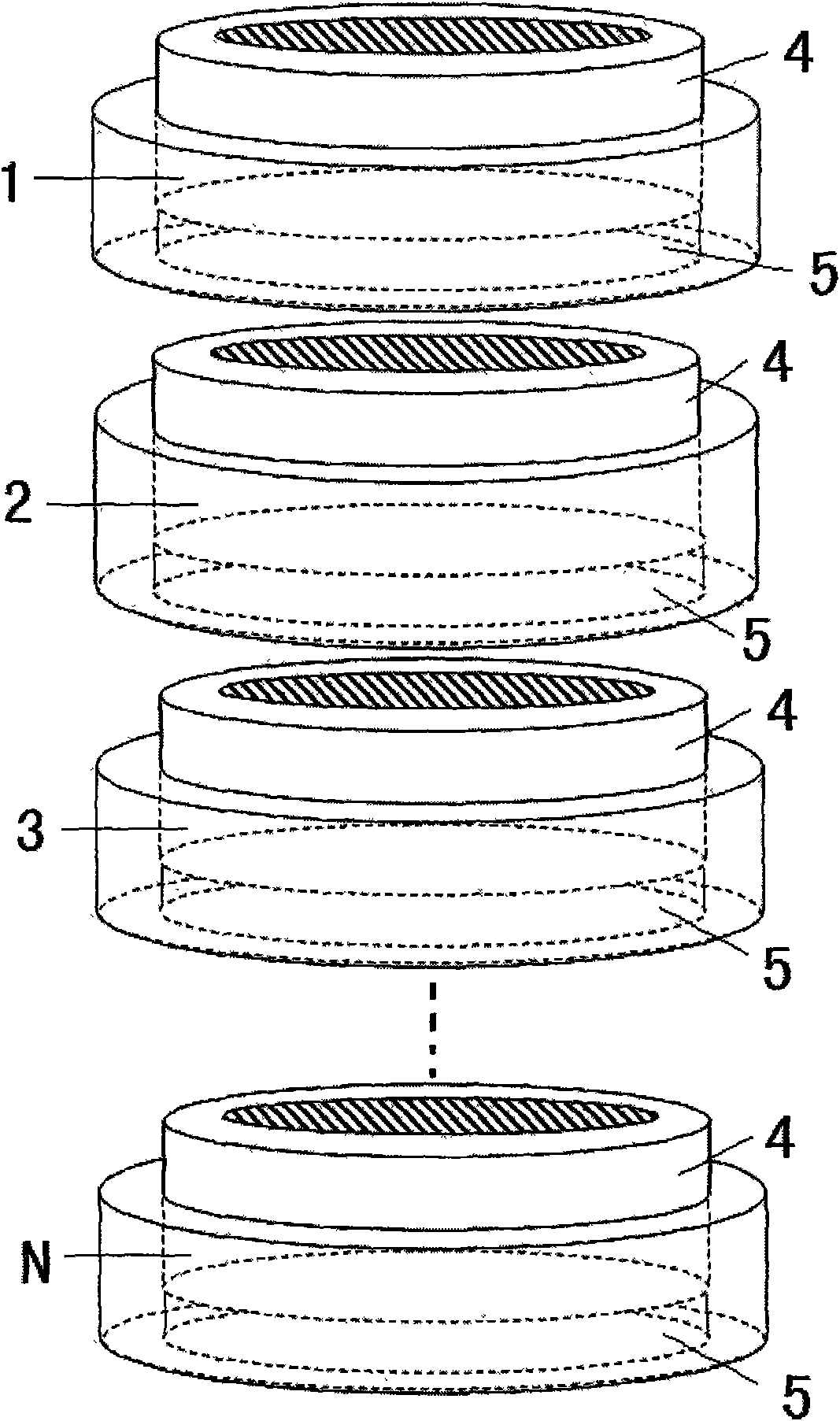

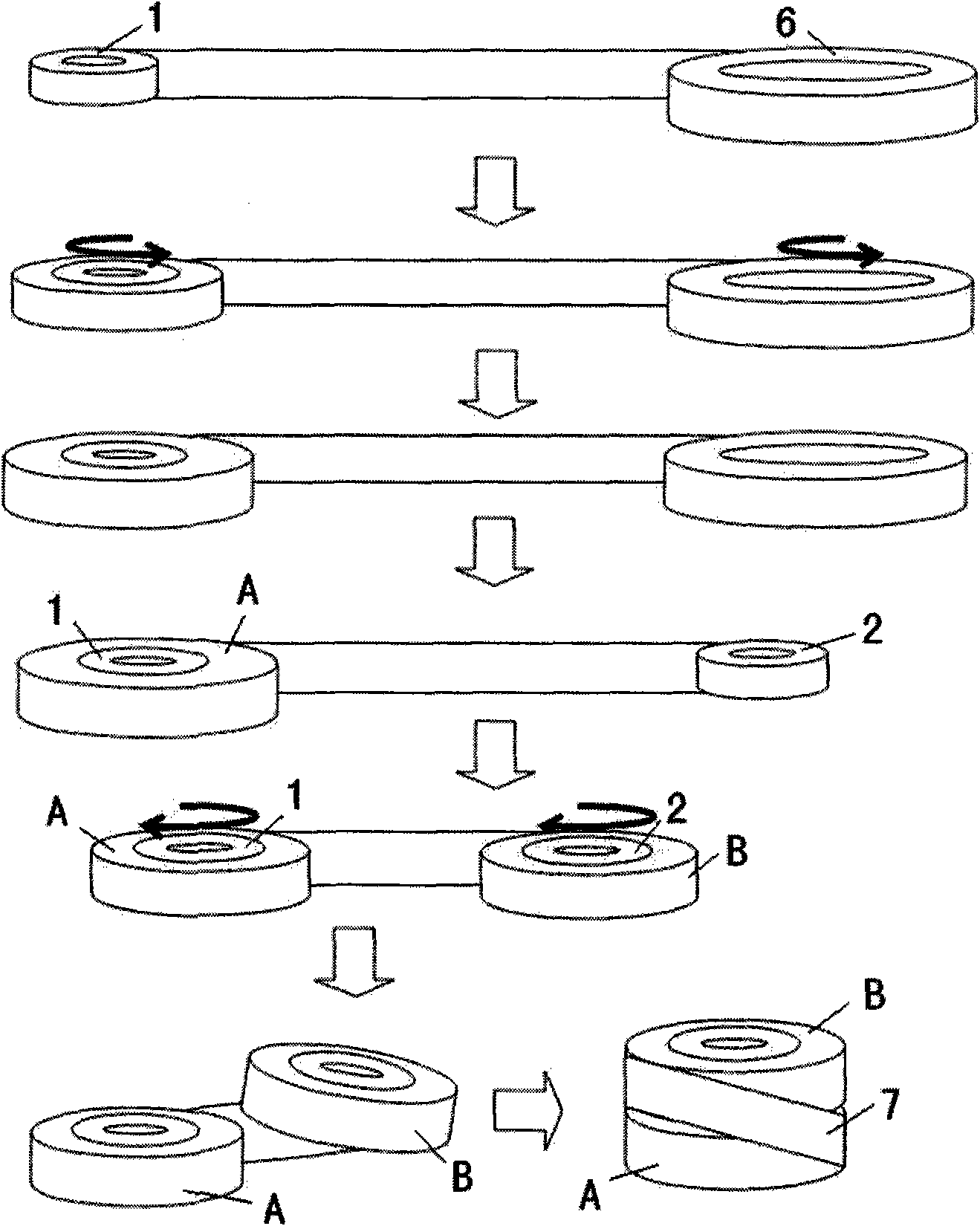

[0027] Such as figure 1 As shown, according to the winding method of the present invention, the winding and assembly steps of the solenoid-shaped magnet of the present embodiment are as follows:

[0028] 1. Design and manufacture of double-cake spools: the spools in the double-cake are spool 1 and spool 2 respectively, and spools 1 and 2 have the same contour and concentric design, both of which are processed with red copper. Wherein, the outermost diameter of the bobbin 1 is 56mm, the innermost diameter is 42mm, and the total length is 7mm. The protruding ring 4 of copper on one side of the bobbin 1 has a length of 2 mm, an outer diameter of 48 mm, and an inner diameter of 42 mm. The other side recessed portion 5 of the spool 1 has a length of 2mm, an outer diameter of 56mm, and an inner diameter of 50mm, so that the outer diameter of the spool 2 is 50mm, and the inner diameter is a tight fit of the ceramic protruding ring 4 of 42mm. The outermost diameter of the spool 2 is 5...

Embodiment 2

[0036] Such as figure 1 As shown, according to the winding method of the present invention, the winding and assembly steps of the solenoid-shaped magnet insulated by polyimide tape in this embodiment are as follows:

[0037] 1. The design and manufacture of double cake spools: the spools in the double cake are made of red copper processing spool 1 and spool 2, and the spools 1 and 2 have circular contours and are concentric. The outermost diameter of the spool 1 is 56mm, the innermost diameter is 42mm, and the total length is 7mm. The protruding ring 4 on one side of the spool 1 has a length of 2 mm, an outer diameter of 48 mm, and an inner diameter of 42 mm. The length of the concave portion 5 on the other side is 2mm, the outer diameter is 56mm, and the inner diameter is 48mm, which is used for tight fitting with the protruding ring 4 of the outer diameter 48mm of the bobbin 2 and the inner diameter 42mm.

[0038] 2. Winding double cakes:

[0039] (1) First fix the positi...

Embodiment 3

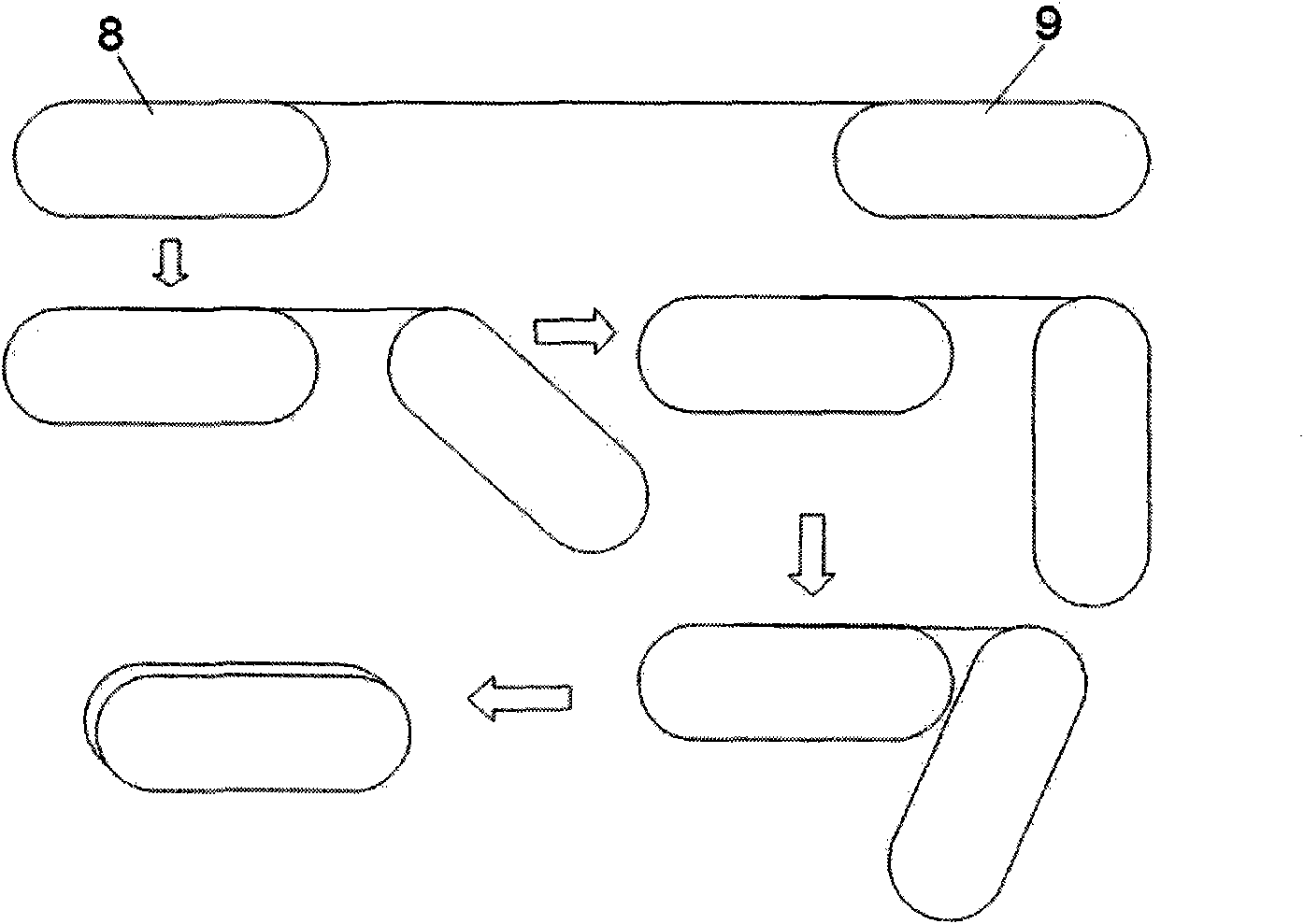

[0045] Such as image 3 As shown, according to the winding method of the present invention, the winding and assembly steps of the racetrack-shaped magnet of the present embodiment are as follows

[0046] 1. Design and manufacture of double cake spools: the design method is similar to that of embodiment 1, except that the shape of the spool becomes a racetrack shape, the size of the semicircles on both sides is the same as that of the half of the circle in embodiment 1, and the straight part in the middle is a length of 60mm.

[0047] 2. Winding double cakes: the winding process requires strict calculations to control the length error of the strip to not exceed 1mm.

[0048] (1) First fix the position of the spool 8 of one of the double cakes, and clean the inner surface of the strip that needs to be attached to the spool 8 from the end point of the strip, and clean the spool at the same time. The outer surface of 8 is cleaned, and the contact surfaces of the two are welded t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com