Sample reservoir for carrying out in-situ characterization on crystallization process of molecular sieve based catalyst, and use method thereof

A technology of catalyst and molecular sieve, which is applied in the direction of material analysis using wave/particle radiation, electromagnetic means, material analysis using radiation diffraction, etc., to achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

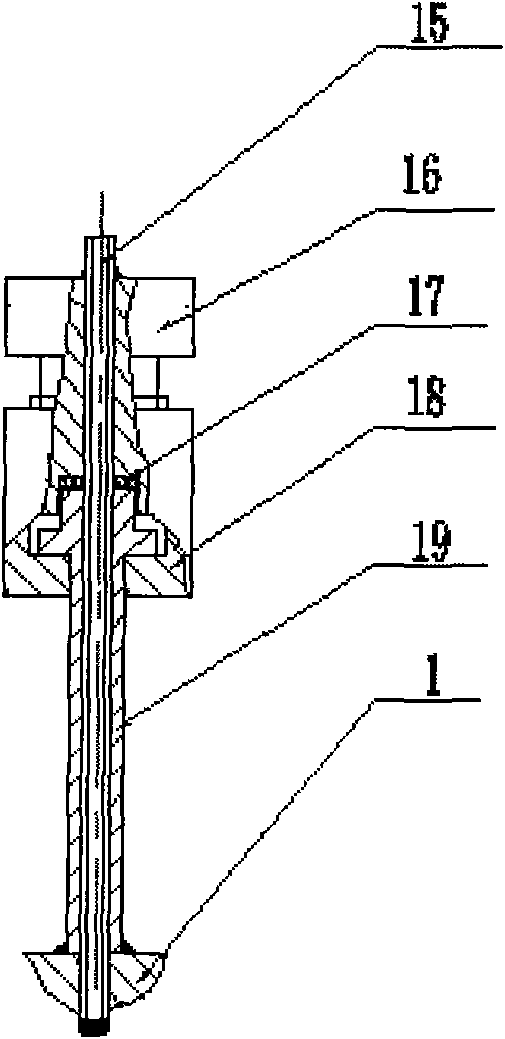

[0034] The pool body 1 is a cylinder with stepped holes, the small holes are through holes, and the stepped large holes at both ends of the pool body 1 are symmetrical; the pool body 1 has a radial circular hole leading from the outer surface to the axis in the radial direction. There is an annular inner core 8 in the small hole of the body 1, and a radial circular hole is arranged in the radial direction of the inner core 8, and the radial circular hole of the inner core 8 communicates with the radial circular hole of the pool body 1, and the inner core 8 has two Each side has a circular window 4,9, and the inner core 8 forms a cavity with the two circular windows 4,9; the sum of the thicknesses of the inner core 8 and the two circular windows 4,9 communicates with the pool body The length of the hole is equivalent, and the end faces of the two stepped holes of the pool body 1 are respectively provided with an annular gasket 3,10; Circular hole 14, there is a long hole 13 in ...

Embodiment 2

[0048] Embodiment 2: wherein the sample imported is a microemulsion molecular sieve precursor; the material of the windows 4,9 is boron nitride ceramics, and the thickness is 2mm; the material of the gaskets 3,10 is polyimide; the thickness of the inner core 8 0.5mm; the material of the gasket 17 is polytetrafluoroethylene; the control temperature is 280°C, and the pressure is self-boosting pressure. All the other are with embodiment 1.

Embodiment 3

[0049] Embodiment 3: wherein the sample introduced is a reverse micellar molecular sieve precursor; the material of the windows 4 and 9 is metal beryllium with a boron nitride thin film deposited on the inner surface, and the thickness is 0.8mm; the material of the gaskets 3 and 10 is polyamide imide; the thickness of the inner core 8 is 2 mm; the material of the gasket 17 is polyimide; the controlled temperature is 300° C., and the pressure is a self-boosting pressure. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com