High-quality pavement petroleum asphalt material and preparation method thereof

A kind of road petroleum asphalt, high-quality technology, used in building insulation materials, building components, construction and other directions, can solve the problem of high-grade road construction that cannot meet heavy load, large traffic volume, lack of high-quality road petroleum asphalt production technology, and high asphaltene content. Advanced problems, to achieve excellent technical performance and road performance, improve the use value, improve the effect of low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

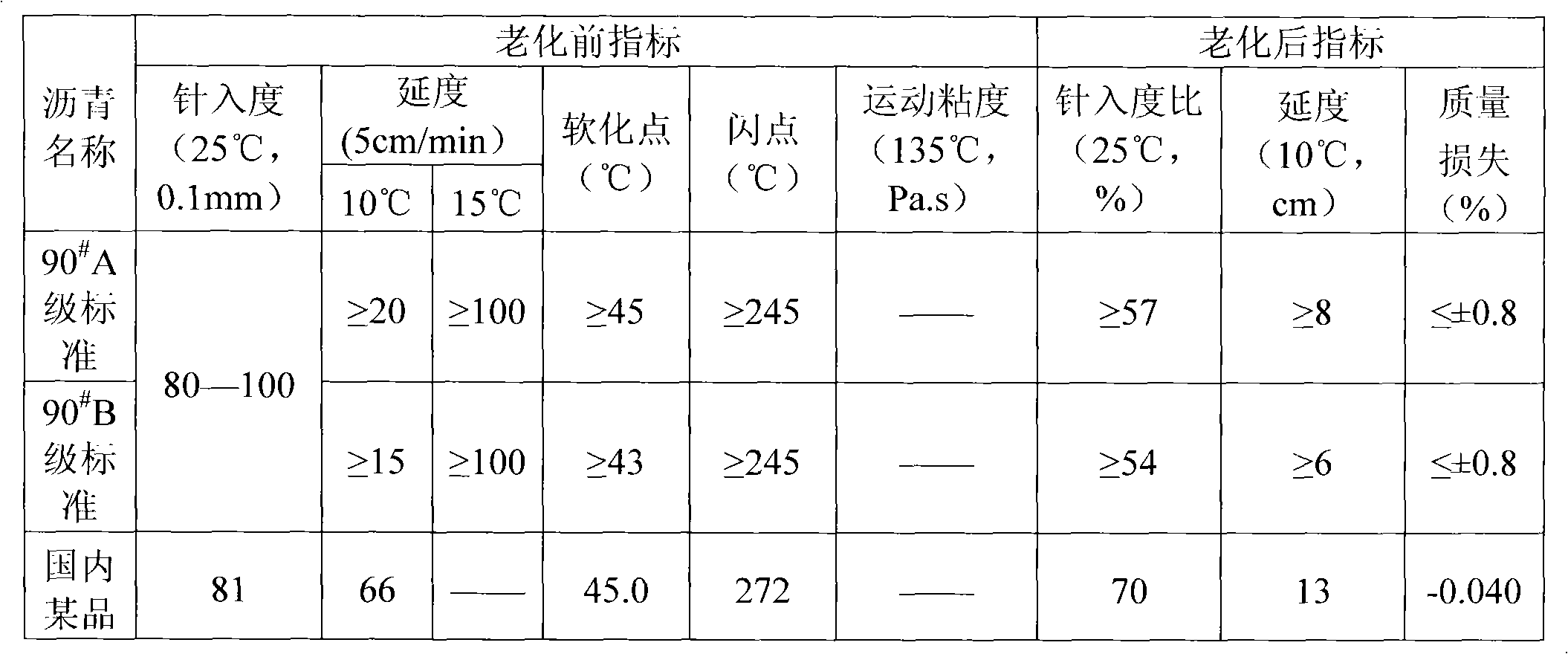

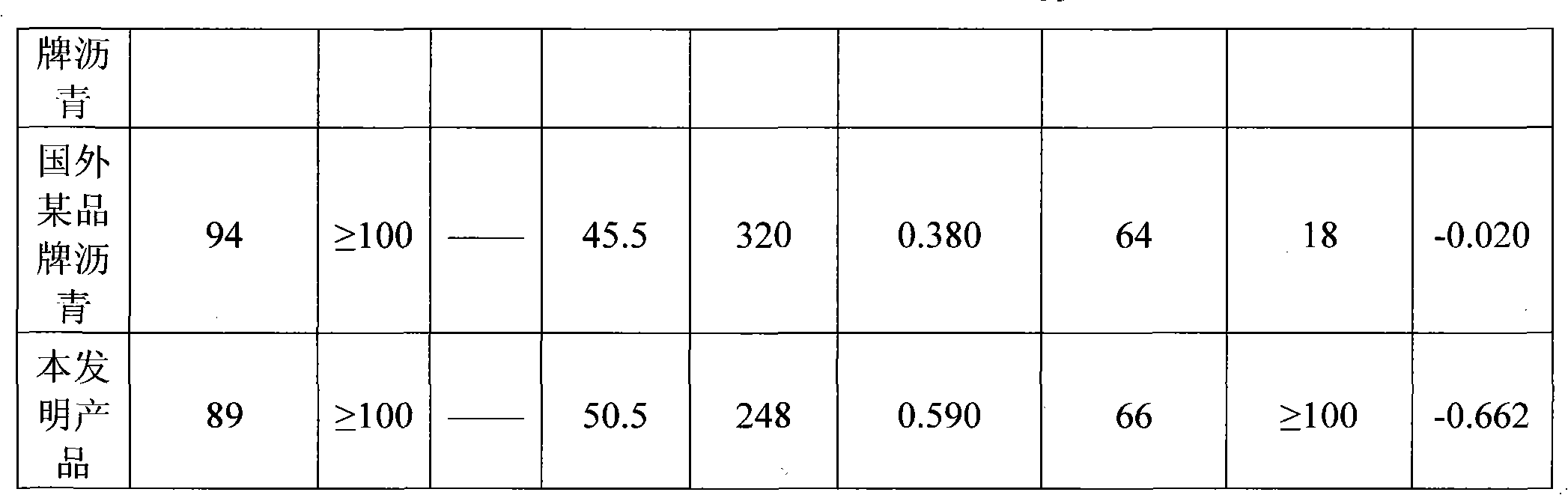

[0029] The high-quality road petroleum asphalt material deployment method of the present invention is as follows:

[0030] 1) Under the condition of 120-200°C, heat 89 parts by mass of the main asphalt to a molten state, pump it into the batching tank, add 1 part by mass of polymer cross-linking agent under the condition of 135°C-140°C, and stir for 30 minutes , after stirring evenly, three-stage high-speed shearing is carried out by a shearing machine;

[0031] 2), pump into the blending tank, add 10 parts of quality blended asphalt and stir evenly;

[0032] 3) Add 0.1 part of mass heat stabilizer, stir for 30 minutes, and then grind it through a colloid mill to obtain high-quality road petroleum asphalt.

[0033] Among them, the main asphalt used refers to the vacuum deep-drawn residual oil and the vacuum residual oil of heavy crude oil, and its four-component content is: asphaltene30%, Aroma > 15%. The blended asphalt used refers to ordinary road petroleum asphalt with h...

Embodiment 2

[0039] The high-quality road petroleum asphalt material deployment method of the present invention is as follows:

[0040] 1) Under the condition of 120-200°C, heat 90 parts by mass of the main asphalt to a molten state, pump it into the batching tank, add 1.2 parts by mass of polymer cross-linking agent under the condition of 140°C-145°C, and stir for 35 minutes , after stirring evenly, three-stage high-speed shearing is carried out by a shearing machine;

[0041] 2), pump into the blending tank, add 8 parts of quality blended asphalt and stir evenly;

[0042] 3) Add 0.05 parts of heat stabilizer by mass, stir for 35 minutes, and then grind it further through a colloid mill to obtain high-quality road petroleum asphalt.

[0043] Among them, the main asphalt used refers to the vacuum deep-drawn residual oil and the vacuum residual oil of heavy crude oil, and its four-component content is: asphaltene30%, Aroma > 15%. The blended asphalt used refers to ordinary road petroleum...

Embodiment 3

[0049] The high-quality road petroleum asphalt material deployment method of the present invention is as follows:

[0050] 1) Under the condition of 120-200°C, heat 87 parts by mass of the main asphalt to the molten state, pump it into the batching tank, add 0.9 parts by mass of polymer cross-linking agent under the condition of 135°C-140°C, and stir for 30 minutes , after stirring evenly, three-stage high-speed shearing is carried out by a shearing machine;

[0051] 2), pump into the blending tank, add 12 parts of quality blended asphalt and stir evenly;

[0052] 3) Add 0.1 part of heat stabilizer by mass, stir for 20-40 minutes, and then grind it through a colloid mill to obtain high-quality road petroleum asphalt.

[0053]Among them, the main asphalt used refers to the vacuum deep-drawn residual oil and the vacuum residual oil of heavy crude oil, and its four-component content is: asphaltene30%, Aroma > 15%. The blended asphalt used refers to ordinary road petroleum asph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com