Modified PVC biologic filler

A biological filler and modified technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor hydrophilic performance and biological affinity, poor thermal stability, impact strength Low problems, to achieve the effect of enhancing hydrophilic performance and flexibility, good heat resistance, and strong impact resistance

Inactive Publication Date: 2011-03-30

LOGISTICAL ENGINEERING UNIVERSITY OF PLA

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Currently, the common polyvinyl chloride biofillers on the market have poor hydrophilicity and bio-affinity, resulting in insufficient film-hanging speed, film-hanging amount, and tightness between the film and the filler. Water and biological affinity modification, activated carbon and magnetic modification are expected to improve the mass transfer, film formation and water treatment performance of the packing

In addition, the impact strength of PVC is only 3 ~ 5kJ / m2, which has the disadvantages of low impact strength and poor thermal stability, which makes the filler easy to age and has a short service life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment

[0036] Element

[0037] According to each embodiment of the above table, the ingredients are prepared, and then the prepared ingredients are mixed and thrown into the feed hopper of the injection molding machine, and extruded through the filler mold.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a modified PVC biologic filler comprising the following components according to part by weight: 4-6 parts of polyvinyl alcohol, 2-4 parts of polyethylene glycol octyl phenyl ether, 2-4 parts of stearic acid, 0.5-1.5 parts of polyacrylamide, 1-3 parts of active carbon, 4-6 parts of magnetic powders and 66.5-79.5 parts of PVC elastomers. The invention mainly carries out hydrophilic modification, active carbon modification, magnetic modification and toughening modification on the PVC biologic filler, enhances the hydrophilic performance and the flexible performance of thebiologic filler, prolongs the contact time of microorganisms and organic substances and further induces the activity of the microorganisms. The obtained microorganism filler enables the biologic filler to have high film hanging speed and large film hanging quantity, and enable a film and the filler to have sufficient compactness. The obtained biologic filler has better heat resisting performance,difficult aging and strong shock resistance capability.

Description

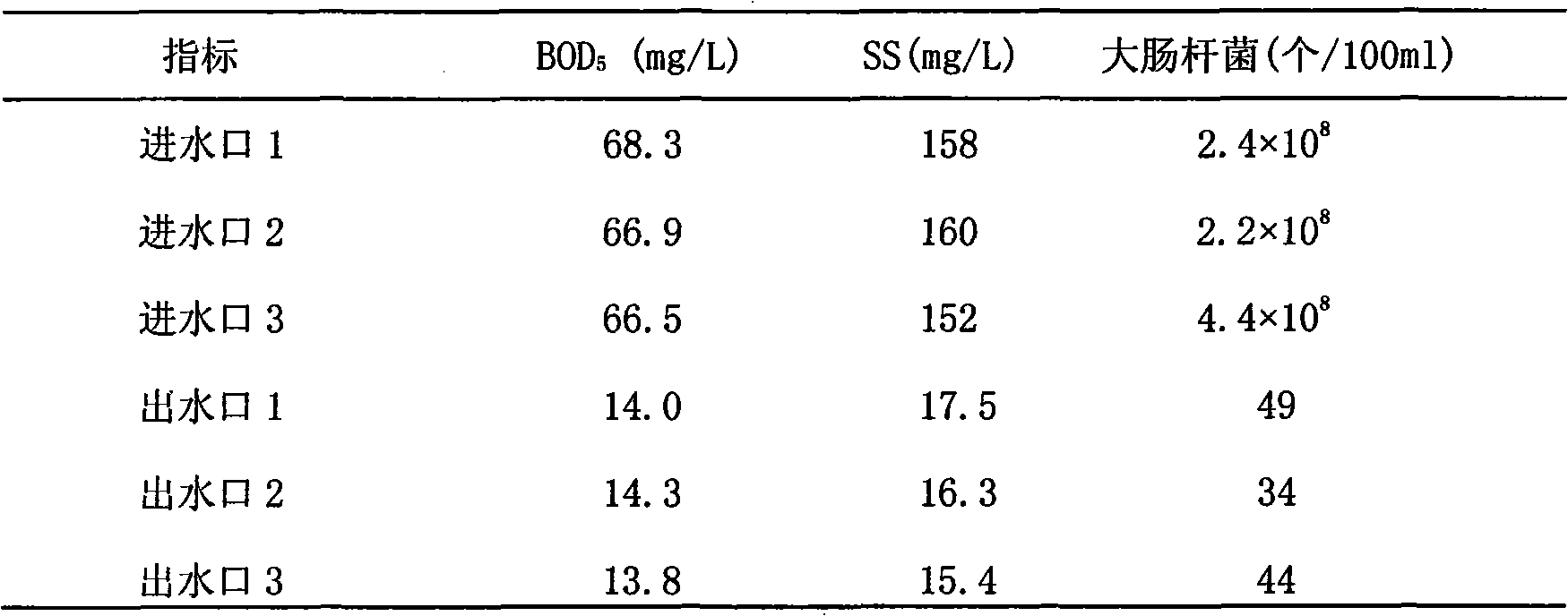

technical field [0001] The invention belongs to biological fillers, in particular to a modified PVC biological filler for biofilm water treatment in sewage treatment. Background technique [0002] Biofiller is one of the cores of wastewater biological treatment technology. Its material and surface properties will directly affect the attachment and growth of microorganisms, and then affect the treatment effect of wastewater. Currently, the common polyvinyl chloride biofillers on the market have poor hydrophilicity and bio-affinity, which lead to deficiencies in the film-hanging speed, the amount of film-hanging, and the tightness between the film and the filler. Water and biological affinity modification, activated carbon and magnetic modification are expected to improve the mass transfer, film formation and water treatment performance of the filler. In addition, the impact strength of PVC is only 3-5kJ / m2, which has the disadvantages of low impact strength and poor thermal ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F3/34C02F3/10

CPCY02W10/10

Inventor 陈志莉熊开生王文标易其臻

Owner LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com