Reversible hot-rolling process of titanium plate coil

A titanium plate and process technology, which is applied in the field of hot rolling process for manufacturing titanium plate and coil, can solve the problems of high production capacity of continuous casting and rolling process, uneven flatness of extension deformation, etc., and achieve improvement of surface quality and mechanical properties, and production automation degree and high productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

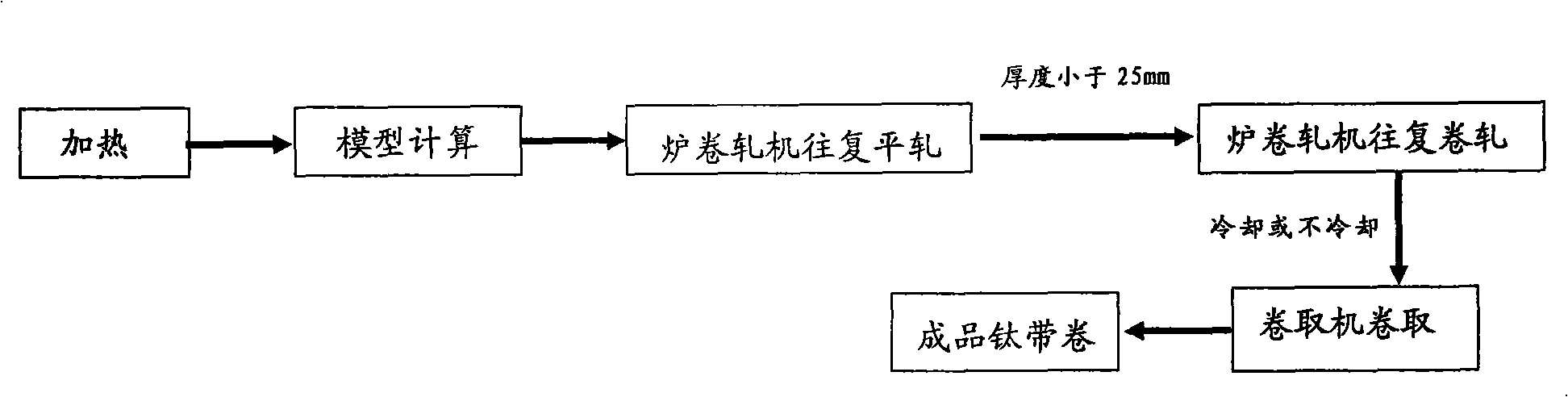

Method used

Image

Examples

example 1

[0032] Put a titanium slab with a specification of 123mm×1290mm×6347mm (thickness×width×length) into the heating furnace, heat it at a heating rate of 0.75mm / min, the furnace temperature is 880°C, the rolling start temperature is 843°C, and the final rolling The temperature is 521°C, and the rolling target thickness is 3.8mm. The distribution of rolling force, speed and reduction of each pass is calculated by the model calculation module as follows:

[0033] pass

[0034] After 14 passes of rolling, the actual thickness of the finished product is 3.74-3.81mm, the average thickness is 3.77mm, which is close to the target thickness of 3.8mm, the width is 1283-1298mm, the average width is 1288mm, and the surface quality reaches the corresponding standard.

example 2

[0036] A titanium slab with a size of 135mm×1285mm×6413mm (thickness×width×length) is loaded into a walking beam heating furnace, heated at a heating rate of 0.77mm / min, the furnace temperature is 900°C, and the rolling temperature is 880°C ℃, the final rolling temperature is 695 ℃, and the rolling target thickness is 3.2mm. The distribution of rolling force, speed and reduction of each pass is calculated by the model calculation module as follows:

[0037] pass

[0038] After 14 passes of rolling, the thickness of the finished product is 3.13-3.25mm, with an average thickness of 3.19mm, which is close to the target thickness of 3.2mm. The average width is 1279mm, and the flatness and surface quality are good, meeting the corresponding standards.

example 3

[0040] Put a titanium slab with a specification of 117mm×1005mm×5227mm (thickness×width×length) into the heating furnace, heat it at a heating rate of 0.55mm / min, the furnace temperature is 880°C, the starting rolling temperature is 860°C, and the final rolling The temperature is 689°C, and the rolling target thickness is 3.5mm. The distribution of rolling force, speed and reduction of each pass is calculated by the model calculation module as follows:

[0041] pass

[0042] After 14 passes of rolling, the thickness of the finished product is 3.41-3.56mm, the average thickness is 3.46mm, which is close to the target thickness of 3.5mm, and the average width is 1013mm. The flatness and surface quality are good, reaching the corresponding standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com