Reuse treating method of flying ash of incinerators

A treatment method and reuse technology are applied in the field of incinerator fly ash reuse treatment, and can solve the problems of low heavy metal dissolution, low water permeability, and low risk of heavy metal dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

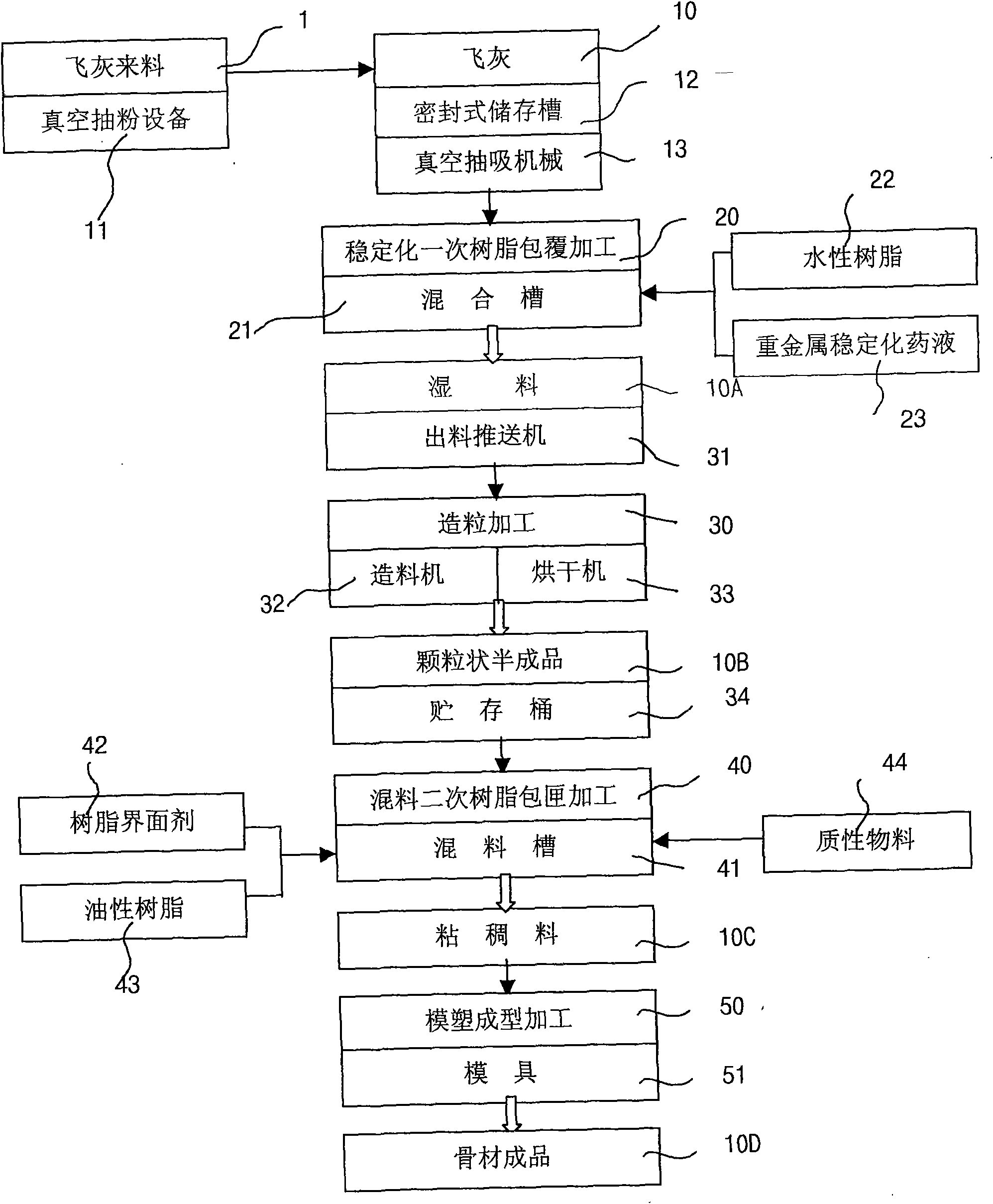

[0011] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0012] A kind of incinerator fly ash reuse processing method, such as figure 1 , is the fly ash 10 stored in the factory, at least through the steps of stabilized primary resin coating processing 20, granulation processing 30, compounding secondary resin encapsulation processing 40, molding processing 50, etc., to complete the non-hazardous engineering skeleton finished material; the stabilized primary resin coating process 20 is to put the fly ash 10 into a closed mixing tank 21 and mix the water-based resin 22 and the heavy metal stabilizing liquid (agent) 23, so that the heavy metals contained in the fly ash can be regenerated The stabilization treatment before utilization is used to form a wet material 10A; the granulation process 30 is to push the wet material 10A of the mixing tank 21 by the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com