Production method of encapsulated component of copper wire bonding IC chip

A chip packaging and bonding technology, used in electrical components, electrical solid devices, semiconductor devices, etc., can solve the problems of quality and reliability, restrict copper wire bonding packaging, IC chip pad craters, etc., and achieve savings The cost of gold wire bonding wire, good economic and social benefits, and the effect of strengthening the strength of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

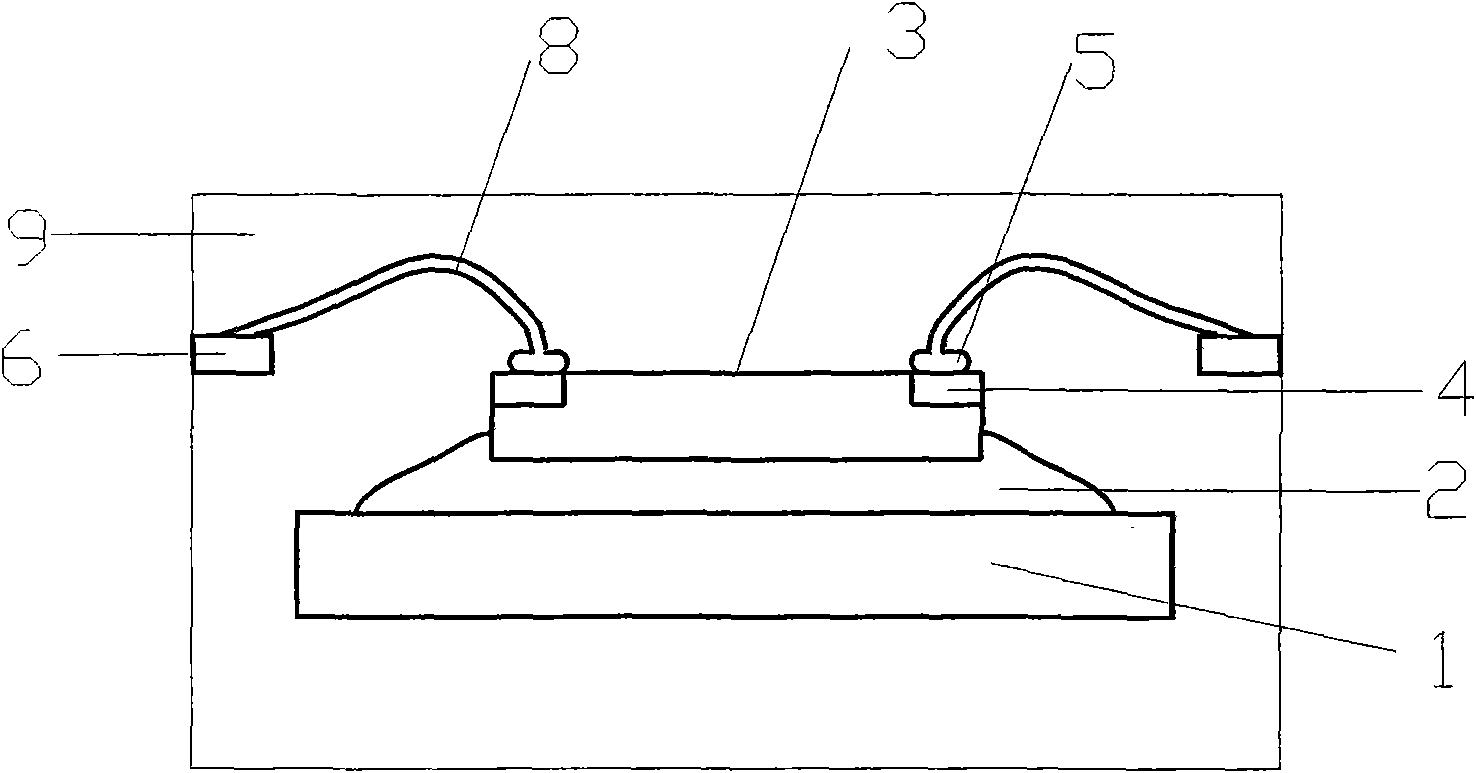

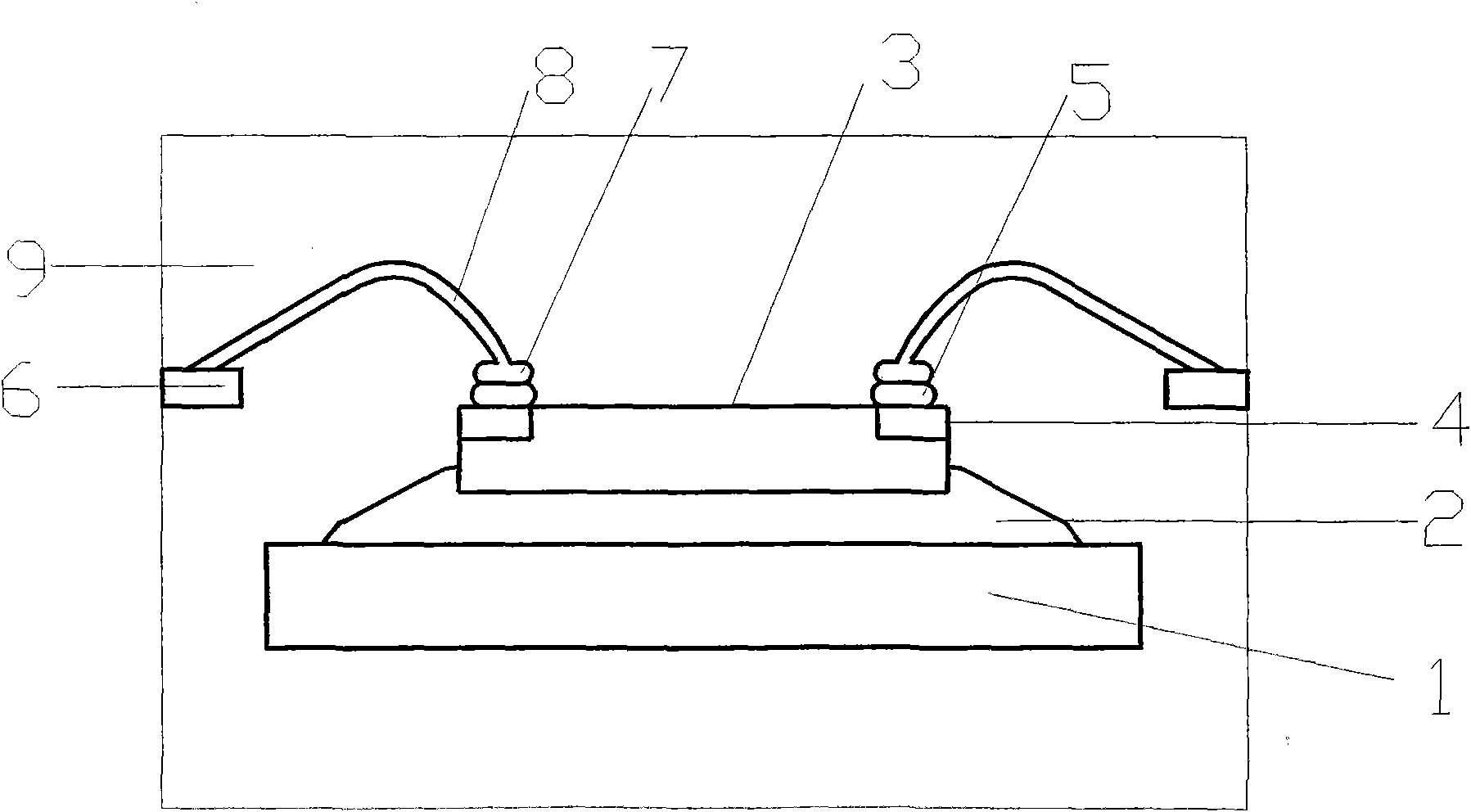

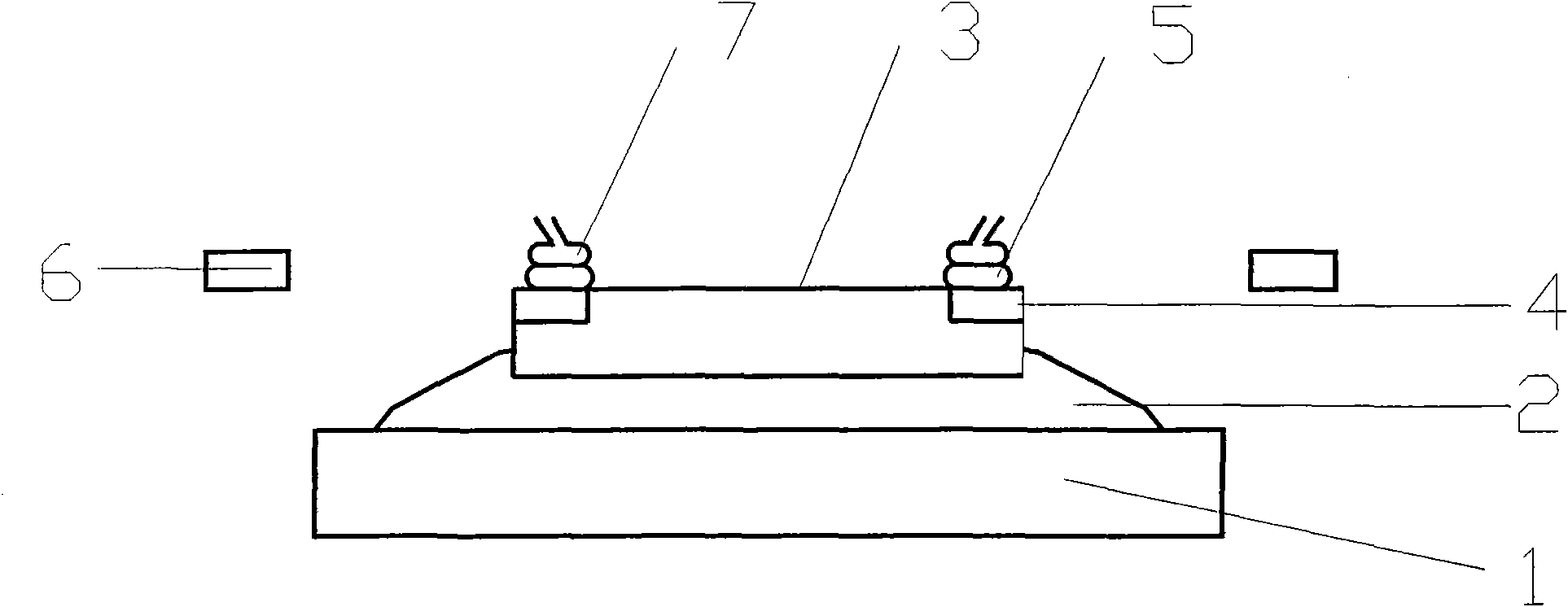

[0028] Thinning, scribing, core loading, plastic encapsulation, post-curing, rib cutting, electroplating, printing, forming separation, and packaging in the full-line process of the production method are the same as those of conventional gold wire and copper wire bonding packaging production, and the pressure welding operation The process is

[0029] 1. Plant golden ball

[0030] Fix the gold wire shaft on the pressure welding station, after the wire is threaded, the frame with the IC chip attached is automatically transferred to the track, and after preheating, it is transferred to the pressure welding fixture. Plant a golden ball on disc 4, and send the frame of the golden ball to the receiving folder after playing;

[0031] 2. Stack the ball

[0032] Fix the copper wire shaft on the pressure welding table, after threading the wire, automatically transfer the frame with gold balls to the track, and transfer it to the pressure welding fixture after preheating, and put gold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com