Catalyst Au/MnOx-CeO2 used for preferential oxidation of carbon monoxide and preparation method thereof

A technology of oxidation catalyst and carbon monoxide, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problems of low CO selectivity and low catalyst PROX activity, etc. To achieve the effect of improved catalytic activity and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

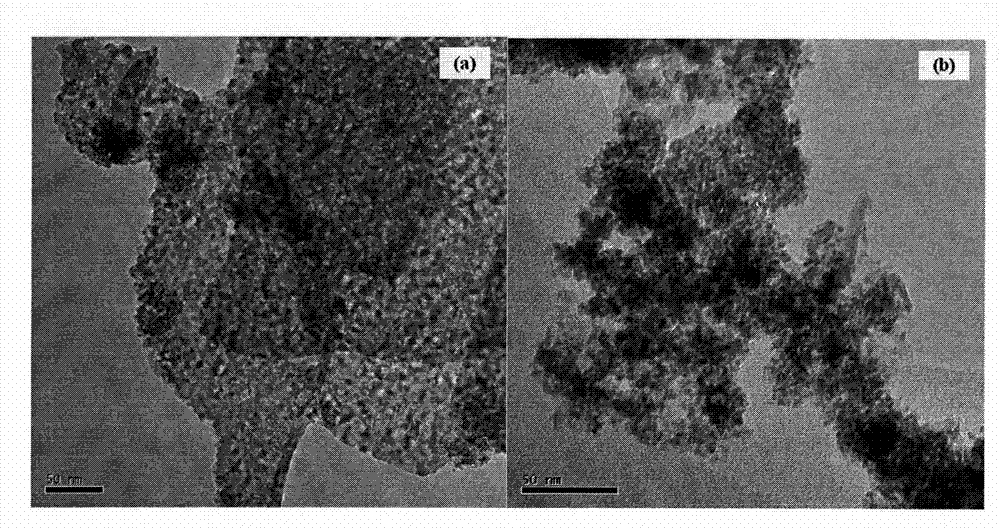

Image

Examples

Embodiment 1

[0015] 1 g of chloroauric acid (HAuCl 4 4H 2 O) be placed in 250mL volumetric flask, add deionized water, be mixed with the active component precursor solution (solution A) that Au concentration is 1.30g / L. Weigh 5.361g Ce(NO 3 ) 3 ·6H 2 O and 3.026gMn(CH 3 COO) 2 4H 2 O was placed in a beaker, and 200 mL of deionized water was added, stirred and dissolved to form a carrier precursor solution (solution B). Under mechanical stirring, add 0.5M Na 2 CO 3 Make it precipitate, adjust the pH = 10.50, keep it constant and stir continuously for 4.5h, then age in a water bath at 50°C for 2h, obtain a precipitate, filter, and dry at a constant temperature of 120°C for 12h, then at 5°C / min The heating rate was increased to 400 ° C, and the constant temperature was roasted for 4 hours to obtain MnO x -CeO 2 Composite oxide support (MnO x for Mn 2 o 3 and MnO 2 mixture). Weigh 3.0g of the obtained carrier and put it in a beaker, add 150mL of deionized water, stir to dissolv...

Embodiment 2

[0019] Weigh 5.361g Ce(NO 3 ) 3 ·6H 2 O and 3.026g Mn(CH 3 COO) 2 4H 2 O was placed in a beaker, and 200 mL of deionized water was added, stirred and dissolved to form a carrier precursor solution (solution B). Under mechanical stirring, add 0.5M Na 2 CO 3 Make it precipitate, adjust the pH = 10.50, keep it constant and stir continuously for 4.5h, then age in a water bath at 50°C for 2h, obtain a precipitate, filter, and dry at a constant temperature of 120°C for 12h, then at 5°C / min The heating rate was increased to 400 ° C, and the constant temperature was roasted for 4 hours to obtain MnO x -CeO 2Composite oxide carrier. Weigh 3.0g of the obtained carrier and put it in a beaker, add 150mL of deionized water, stir to dissolve, and use an ultrasonic cleaner with a power of 100W and a frequency of 40KHz to assist in dissolving for 5 minutes; measure 23.1mL of solution A, put it in a beaker, add Prepare 152mL of 1.0mmol / L Au solution with deionized water, and then add...

Embodiment 3

[0022] Weigh 5.361g Ce(NO 3 ) 3 ·6H 2 O and 3.026g Mn(CH 3 COO) 2 4H 2 O was placed in a beaker, and 200 mL of deionized water was added, stirred and dissolved to form a carrier precursor solution (solution B). Under mechanical stirring, add 0.5M Na 2 CO 3 Make it precipitate, adjust the pH = 10.50, keep it constant and stir continuously for 4.5h, then age in a water bath at 50°C for 2h, obtain a precipitate, filter, and dry at a constant temperature of 120°C for 12h, then at 5°C / min The heating rate was increased to 400 ° C, and the constant temperature was roasted for 4 hours to obtain MnO x -CeO 2 Composite oxide carrier. Weigh 3.0g of the obtained carrier and put it in a beaker, add 150mL of deionized water, stir to dissolve, and use an ultrasonic cleaner with a power of 100W and a frequency of 40KHz to assist in dissolving for 5 minutes; measure 23.1mL of solution A, put it in a beaker, add Prepare 152mL of 1.0mmol / L Au solution with deionized water, and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com