Vacuum switch and vacuum switchgear

A vacuum switch and equipment technology, which is applied to electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of insulation damage and inability to cover insulation cylinders, etc., and achieve the effect of higher insulation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

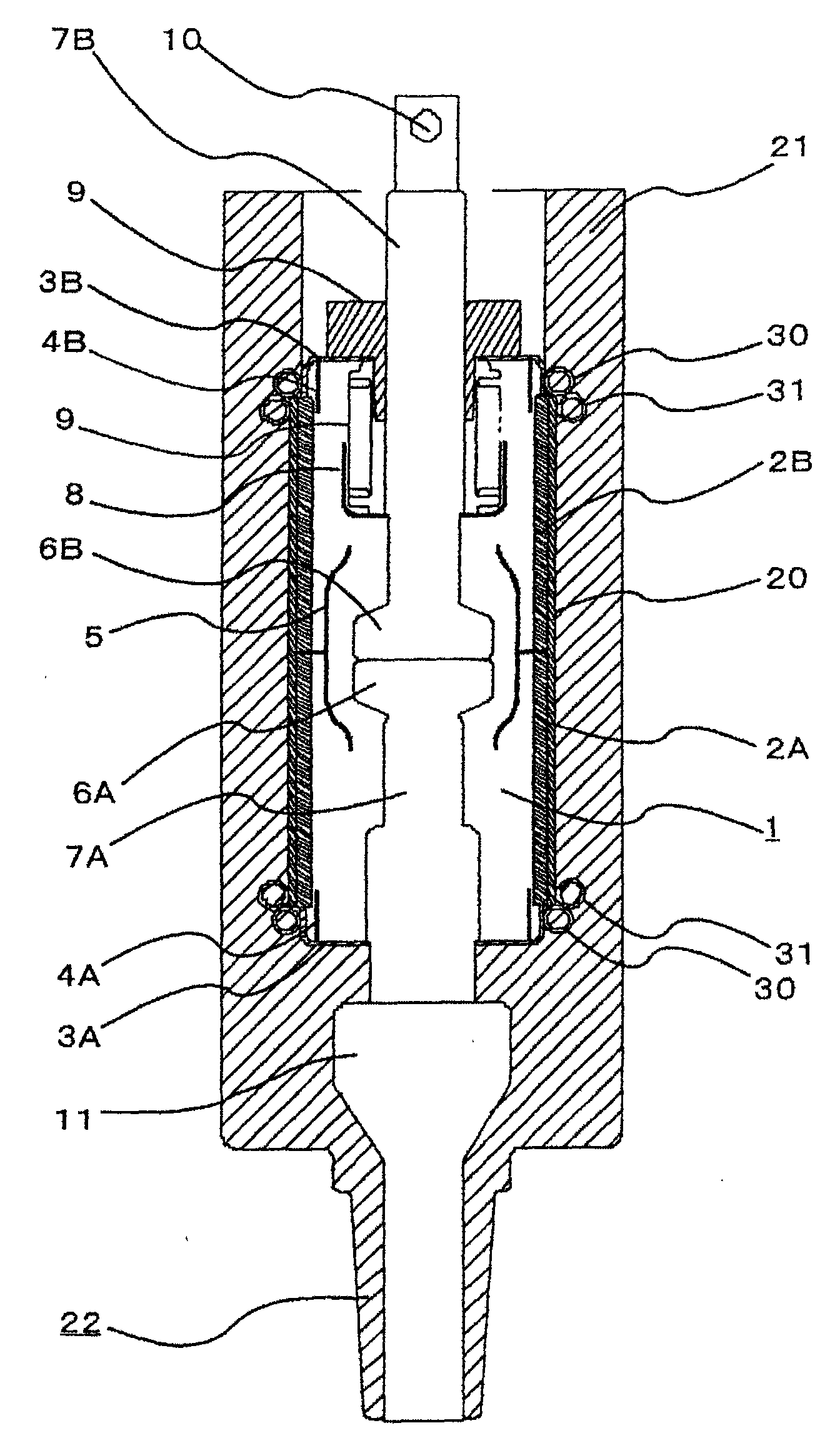

[0033] use Figure 1 to Figure 5 A first embodiment of the vacuum switch of the present invention will be described.

[0034] Such as figure 1 As shown, the vacuum switch 1 of this embodiment roughly includes: a vacuum container 2 ; fixed and movable electrodes 6A and 6B arranged in the vacuum container 2 ; and a solid insulating resin 21 covering the periphery of the vacuum container 2 .

[0035] The vacuum container 2 includes: a fixed-side ceramic insulating cylinder 2A; a movable-side ceramic insulating cylinder 2B connected to the fixed-side ceramic insulating cylinder 2A; 2A, 2B thin metal fixed-side end plate 3A; and metal movable-side end plate 3B connected to the axially movable side of the movable-side ceramic insulating cylinder 2B, the inside of which is kept in a high vacuum state. In order to achieve bonding with the metallic end plates 3A, 3B on the bonding surfaces of the insulating cylinders 2A, 2B with the two end plates 3A, 3B, thermal bonding (metallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com