Environmental-friendly efficient hot air circulating system and recycling method

A circulating system and environment-friendly technology, applied in the field of environment-friendly and high-efficiency hot air circulation system and recycling, can solve the problems of lack of heat energy recovery device, inability to achieve uniform drying, and inability to realize full utilization of heat energy cycle, so as to reduce heat energy loss and achieve The effect of making full use of thermal energy and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

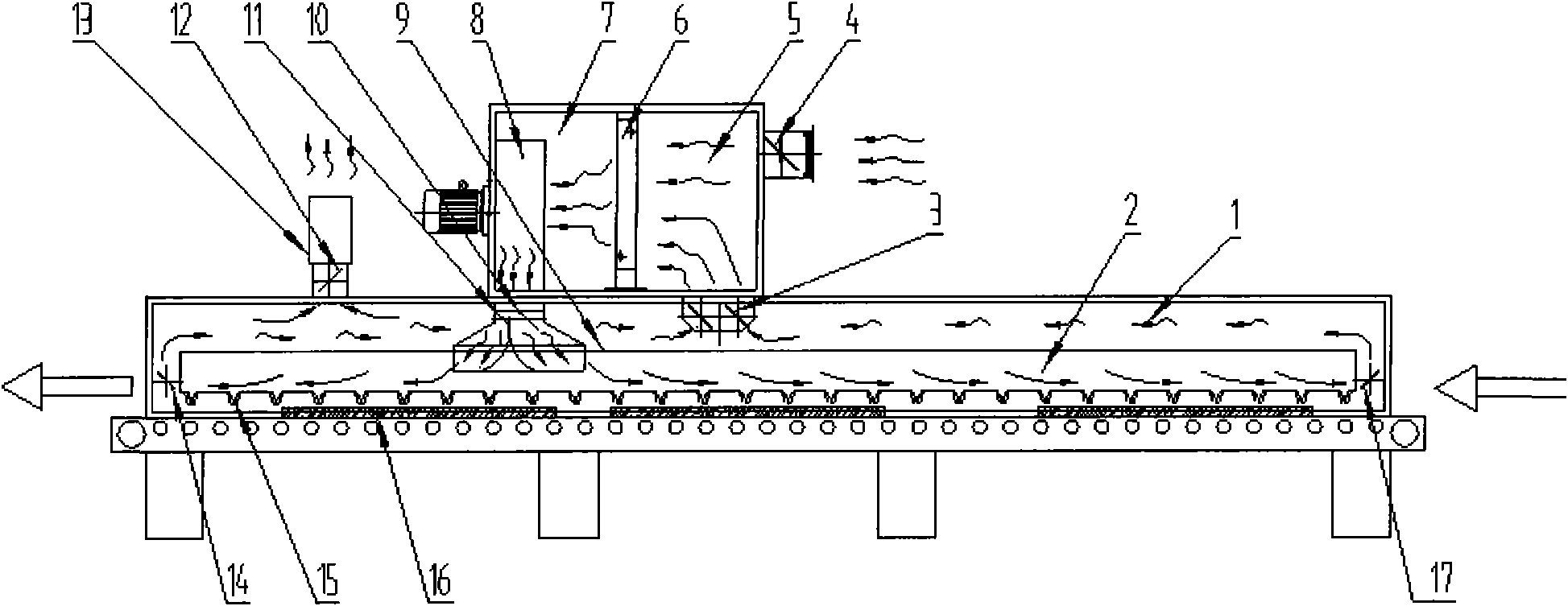

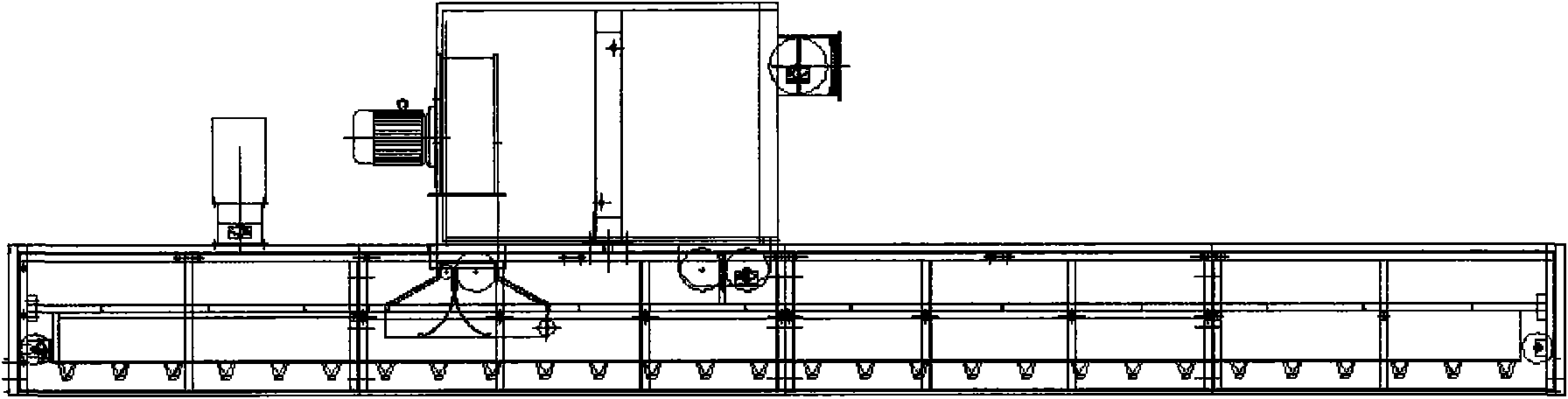

[0010] Embodiment 1: with reference to attached Figure 1~2 . An environment-friendly high-efficiency hot air circulation system, which includes a drying system. There is a cover on the upper part of the heated workpiece 16 of the drying system, and an airtight container is arranged on the upper part of the cover. One end of the container is provided with a valve baffle 4. A gas mixing chamber 5 is provided on the part in contact with the valve baffle plate 4, a heater 6 is arranged at the other end of the gas mixing chamber 5, and an air suction chamber 7 is arranged next to the heater 6. The joint part is provided with a valve baffle 3 to control the circulating hot mixed air entering the mixing chamber 5, and a circulating fan 8 is provided at the other end of the airtight container, and extends to the inside of the pressurized air duct 9, and the inside of the cover is provided There is a pressurized air duct 9, and uniformly distributed air outlet nozzles 15 are arranged...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the recycling method of the environment-friendly high-efficiency hot air circulation system, the tunnel hot air 2 passes through the air nozzle 15 and acts on the workpiece 16, and then is divided into two parts. One part of the wet and dirty air is discharged through the valve 12 and the fan 13 system, another part of the hot mixed air 1 enters the air mixing chamber 5 through the valve 3, together with the fresh air entering the air mixing chamber 5 through the valve 4, it is heated by the heater 6 to form dry hot air and enters the suction chamber 7, and then passes through the circulating fan 8, Valve 10 and valve 11 form pressurized working hot air 2 in pressurized air duct 9, and then act on the surface of workpiece 16 through air outlet 15, thus completing the recycling process of hot mixed air 1 in the whole system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com