Supersonic condensation and cyclone separation device

A cyclone separation device, supersonic technology, applied in cyclone devices, devices whose axial direction of cyclone remains unchanged, solidification and other directions, can solve the problem of large total pressure loss, poor flow field uniformity, affecting separation efficiency and pressure. Recycling efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

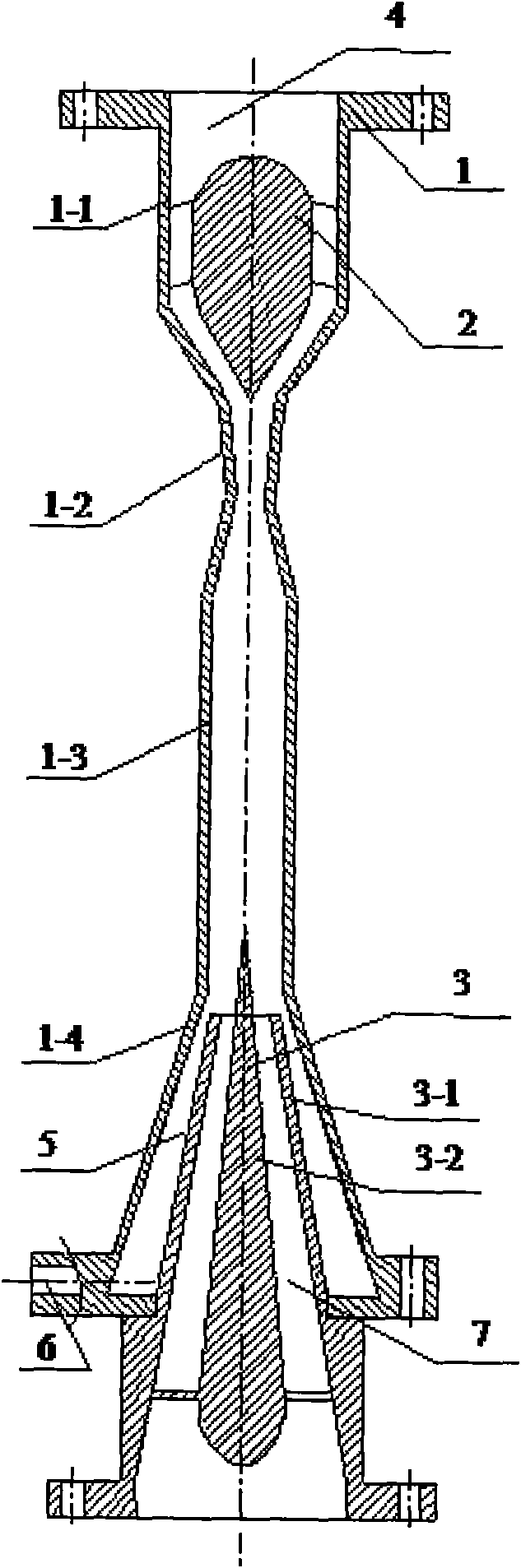

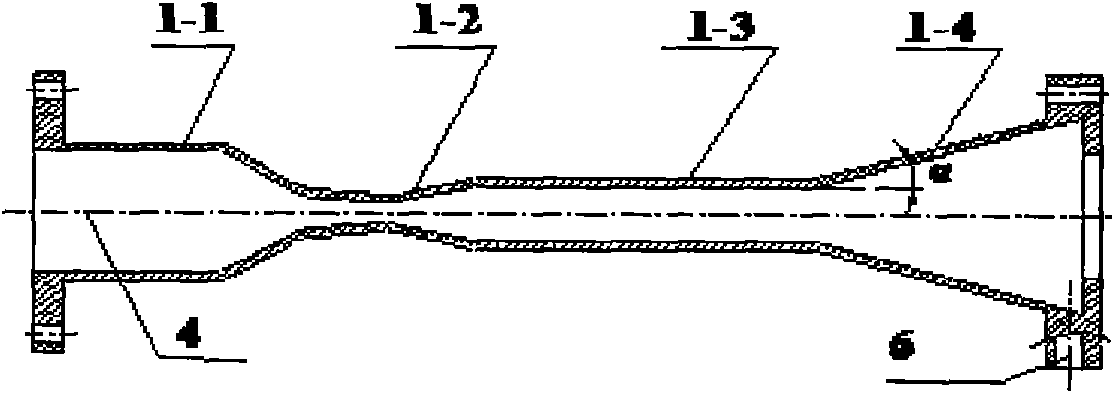

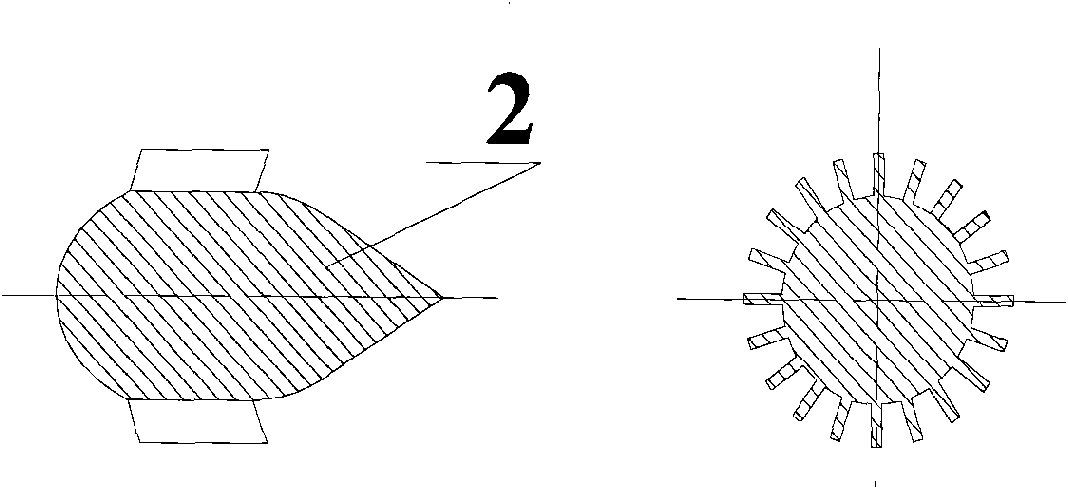

[0016] see figure 1 , 2, the present invention comprises the pipeline 1 that is made up of the inlet section 1-1 that is provided with gas inlet 4, scaling section 1-2, equal straight section 1-3 and expansion section 1-4, in the inlet section 1-1 of pipeline 1 1 is provided with a diversion spindle body 2 with cascades, an annular channel is formed between the diversion spindle body 2 with cascades and the pipeline 1, and a swirl recovery booster 3 is provided at the expansion section 1-4 of the pipeline 1, The swirl recovery booster 3 includes a housing 3-1 and a central cone 3-2 arranged in the housing 3-1, an annular gas outlet 7 is formed between the central cone 3-2 and the housing 3-1, and the housing 3 A liquid collection chamber 5 is formed between -1 and the expansion section 1-4 of the pipeline 1, and a liquid discharge port 6 is also opened at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com