Braking cylinder of braking device of railway wagon

A technology of braking device and railway freight car, applied in railway car body parts, brake parts, brake type and other directions, can solve the problems of poor sealing performance, reduced reliability of brake cylinder, shortened service life, etc. The effect of reducing sealing performance, manufacturing accuracy requirements, and prolonging working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The brake cylinder of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

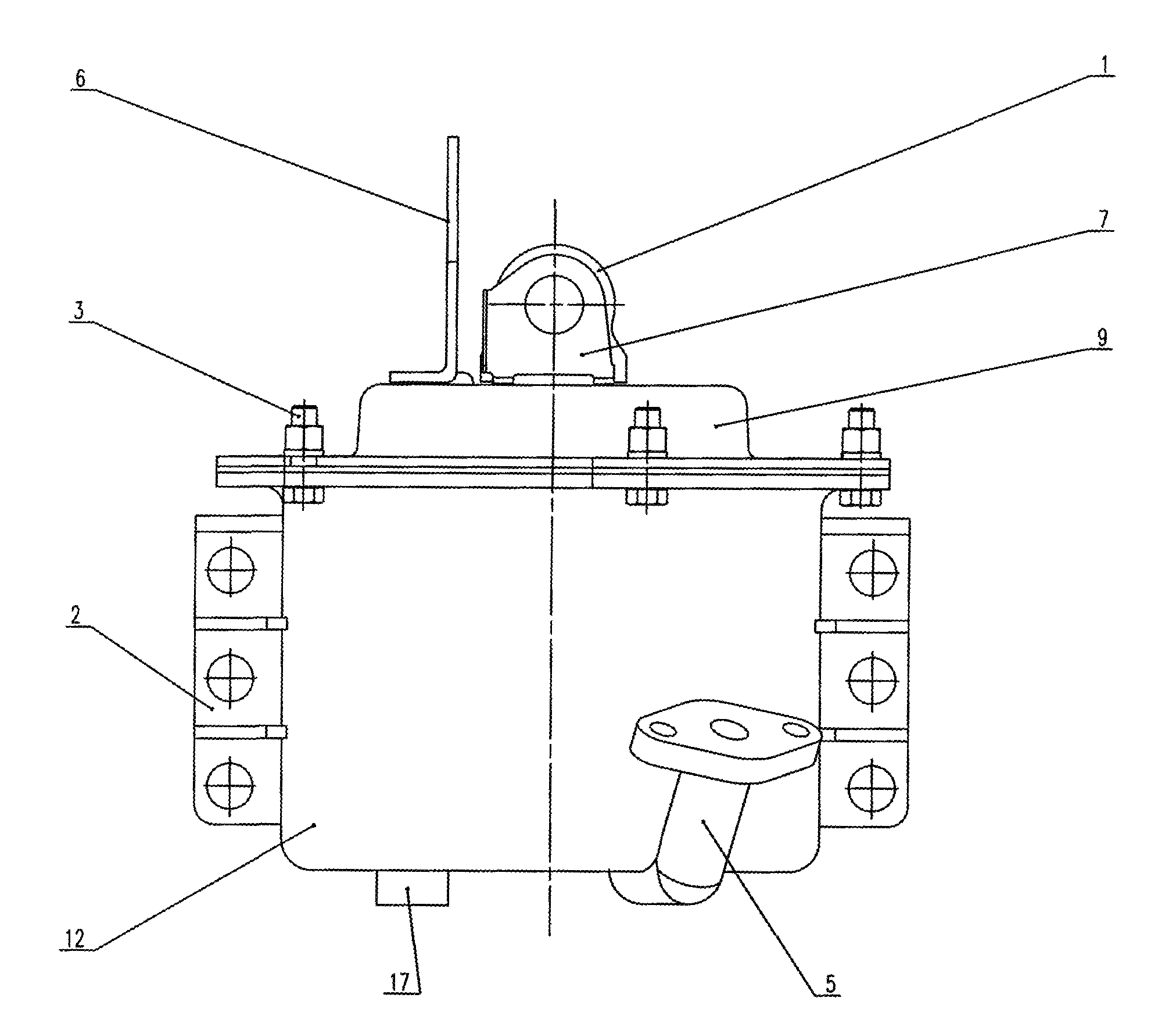

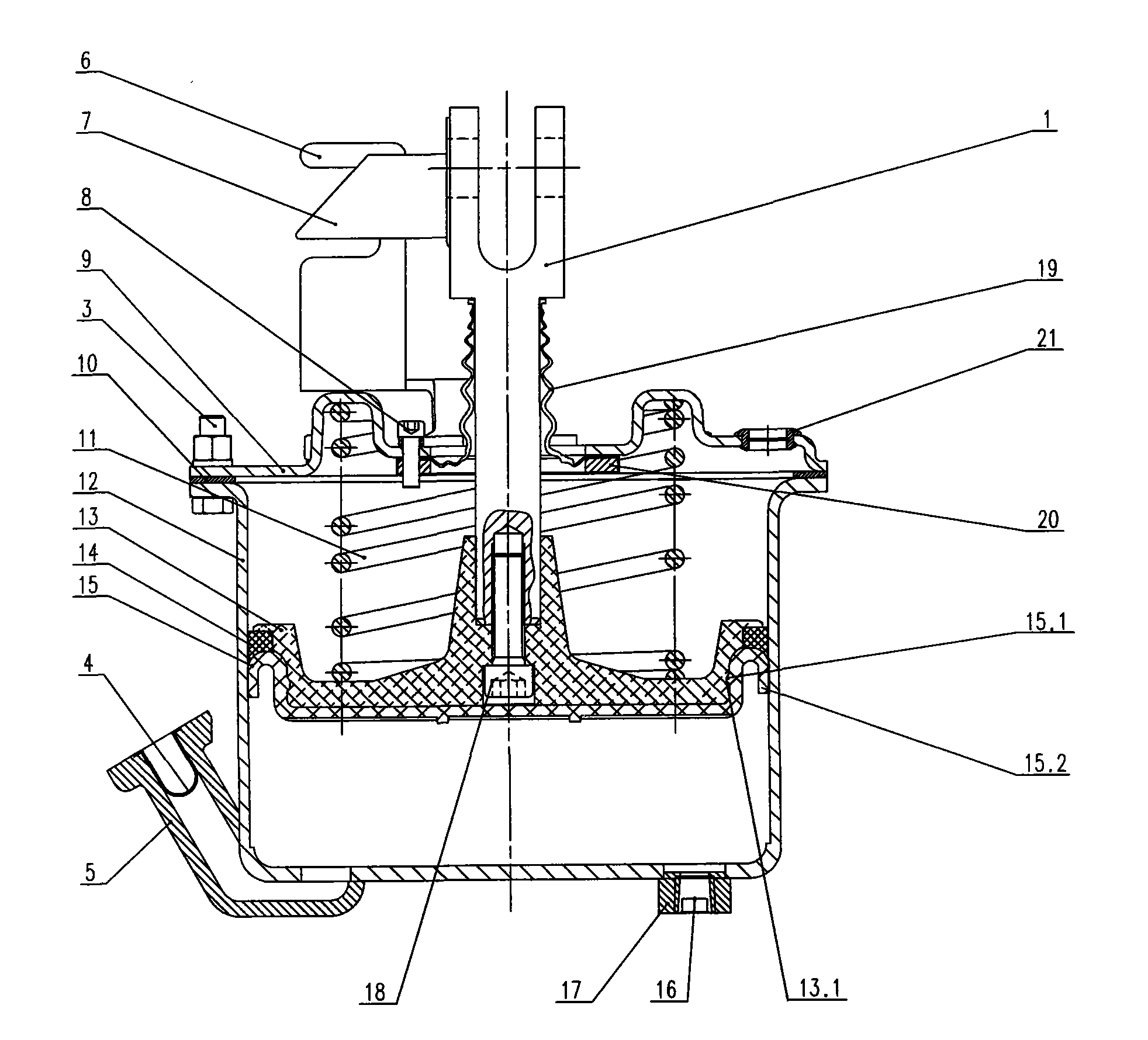

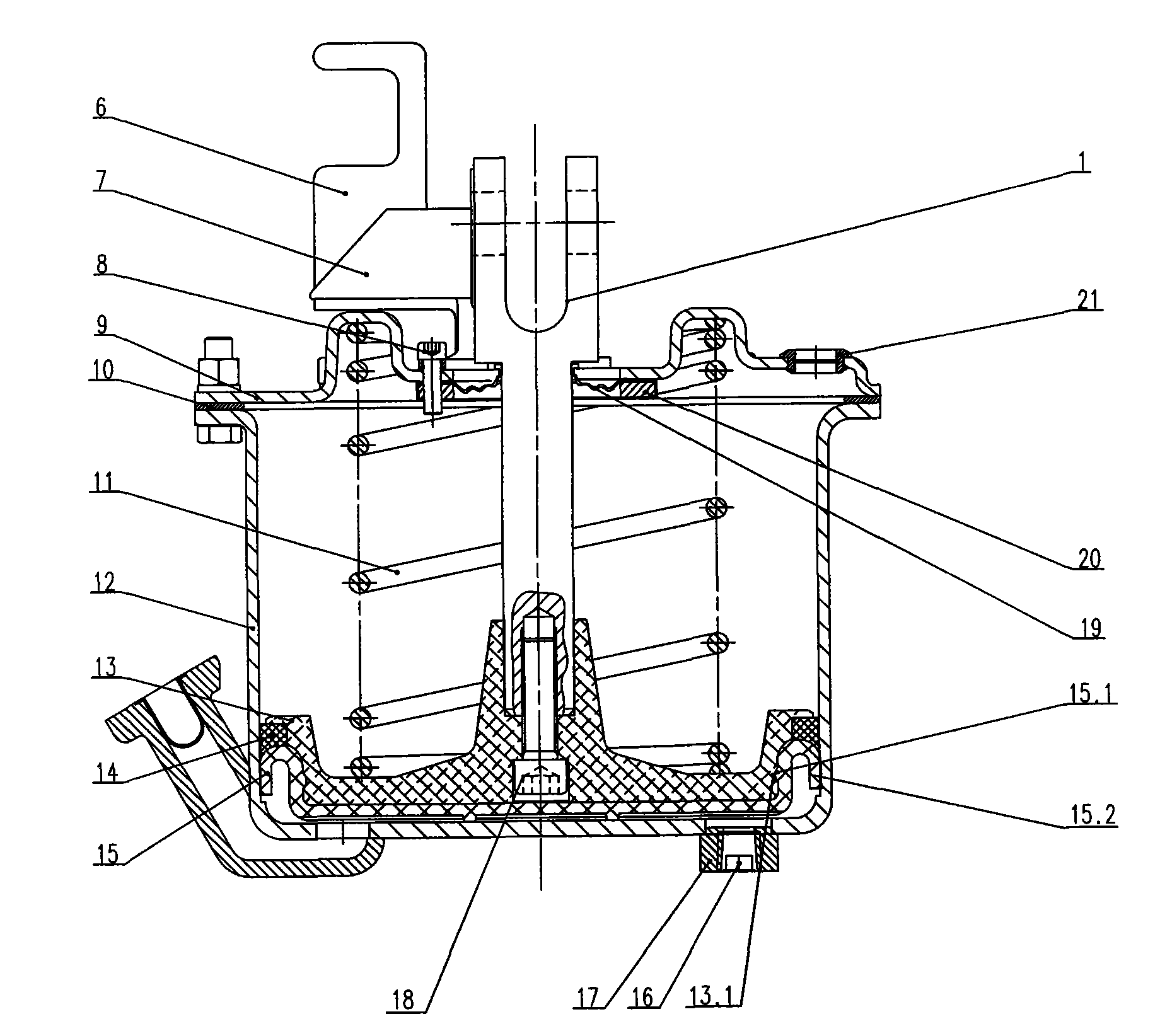

[0017] The brake cylinder of the railway wagon braking device shown in the figure includes a cylinder body 12 and a cylinder head 9, and the cylinder body 12 and the cylinder head 9 can be made of stainless steel to improve their corrosion resistance and service life. The cylinder block 12 is made by a spinning process, and is fixedly mounted on the cylinder block 2 . The cylinder head 9 is fastened on the cylinder block 12 through the bolt assembly 3 and the liner 10 . One side of the bottom of the cylinder body 12 is welded with an air inlet and outlet flange elbow 5 , and a dust filter 4 is arranged in the air inlet and outlet flange elbow 5 to prevent dust particles in the air from being sucked in the cylinder body 12 . The other side of the bottom of the cylinder body 12 is provided with a pipe joint 17 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com