Conformal compressing tool of wing wallboard

A technology for wall panels and tooling, applied in the field of digital assembly of large aircraft, can solve the problems of low hole-making accuracy and connection accuracy, weak rigidity, and long and narrow dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

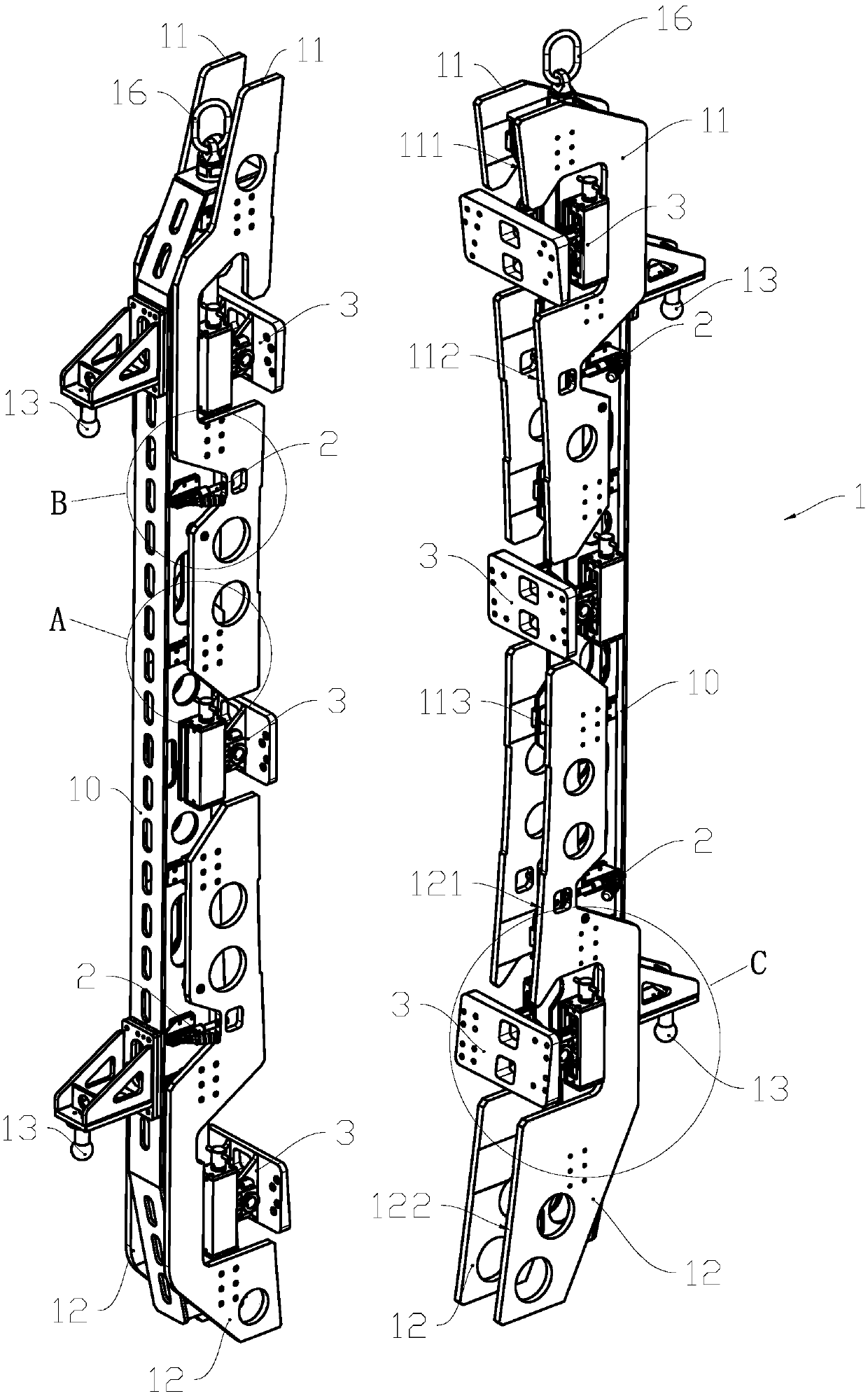

[0031] see Figure 1 to Figure 13 , in this embodiment, the siding shape-retaining tooling includes the main shape-preserving frame 1 installed at the wing root and the main body of the siding, the wingtip auxiliary shape-preserving frame 4 installed at the wing tip of the siding, and used for A pressing plate mechanism 7 that compresses the wall plate and the wing rib frame where the shape-preserving frame is not installed. in, figure 1 Shown are a pair of upper and lower primary conformal frames, Image 6 , 7 Shown is a pair of upper and lower wingtip assist conformal tooling.

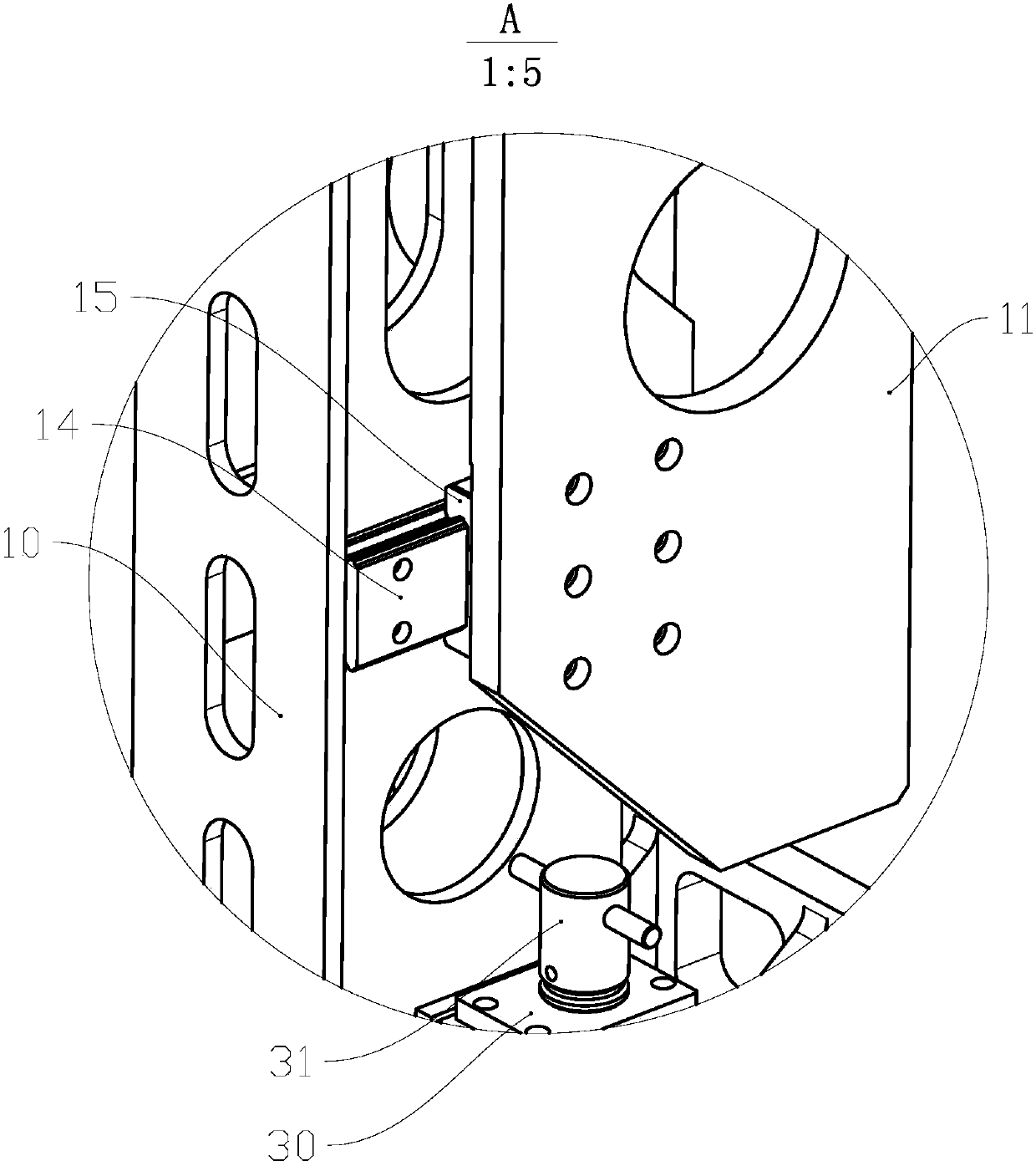

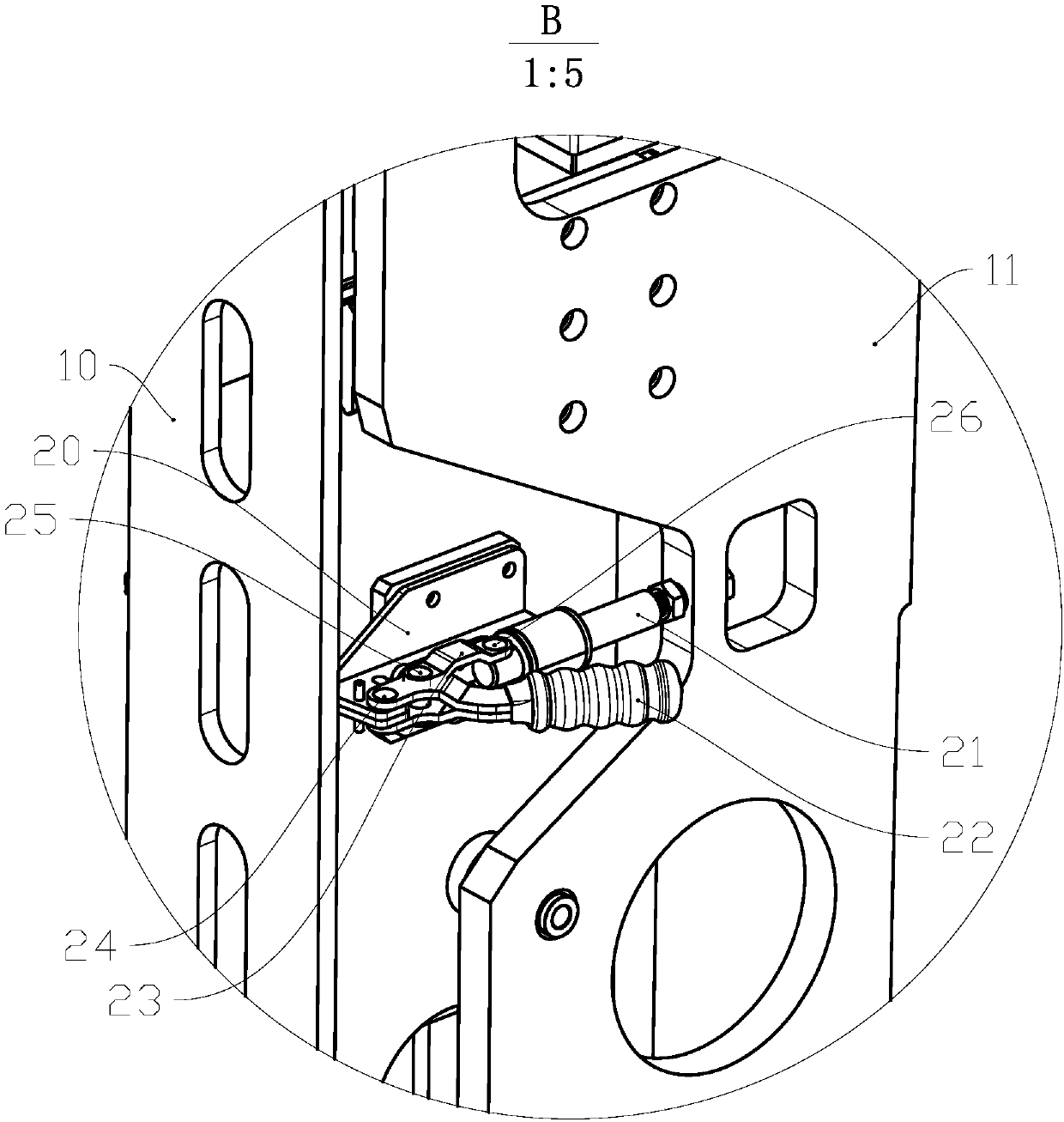

[0032] Such as Figure 1 to Figure 5 As shown, the main shape retaining frame 1 includes a support frame 10 and a wall panel connecting mechanism 3 and a wall panel pressing member installed on the support frame 10 .

[0033] The support frame 10 is a panel structure whose length is arranged along the course of the wall panel and whose width is arranged along the span direction of the wall panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com