Full-automatic continuous filtering and filter pressing slag unloading machine

A fully automatic and slag discharge technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor filtration effect, increased processing difficulty, and increased equipment manufacturing costs, and achieve enhanced filtration capacity and filtration efficiency. The effect of improving and reducing assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

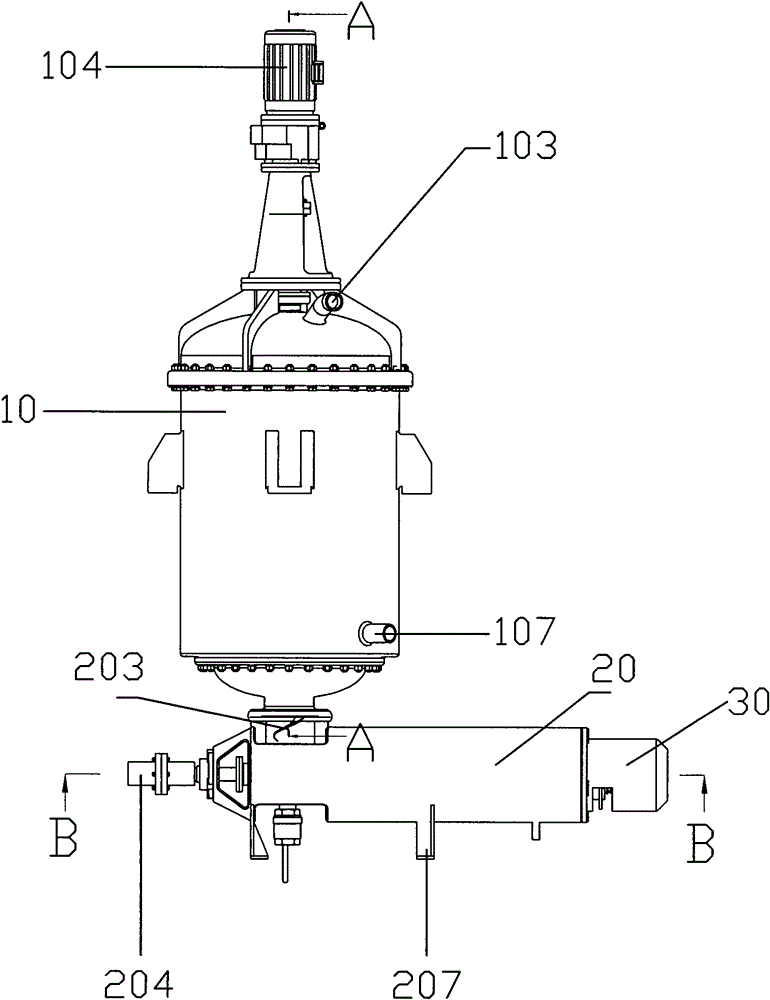

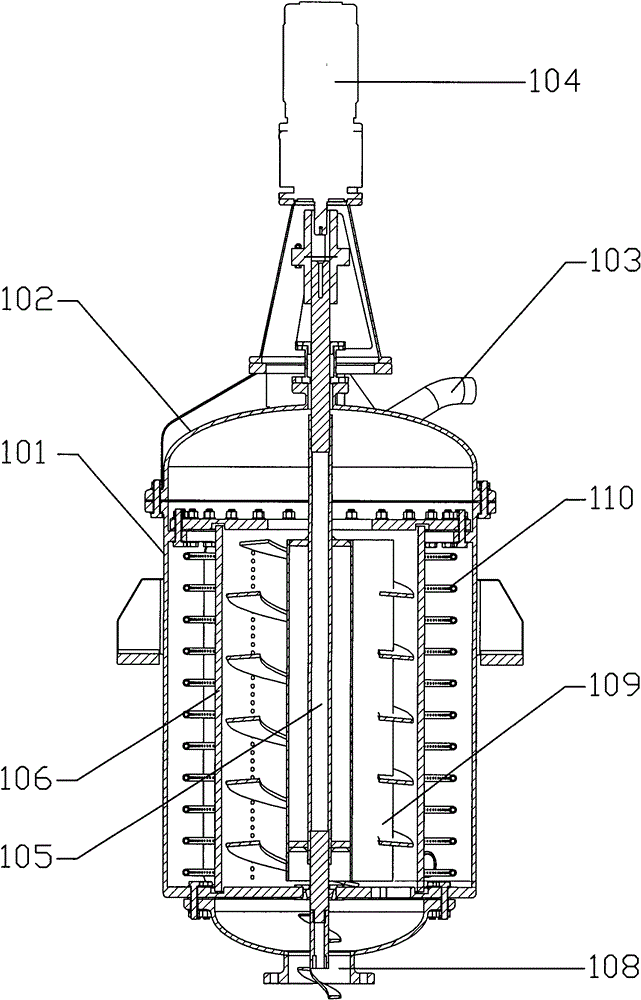

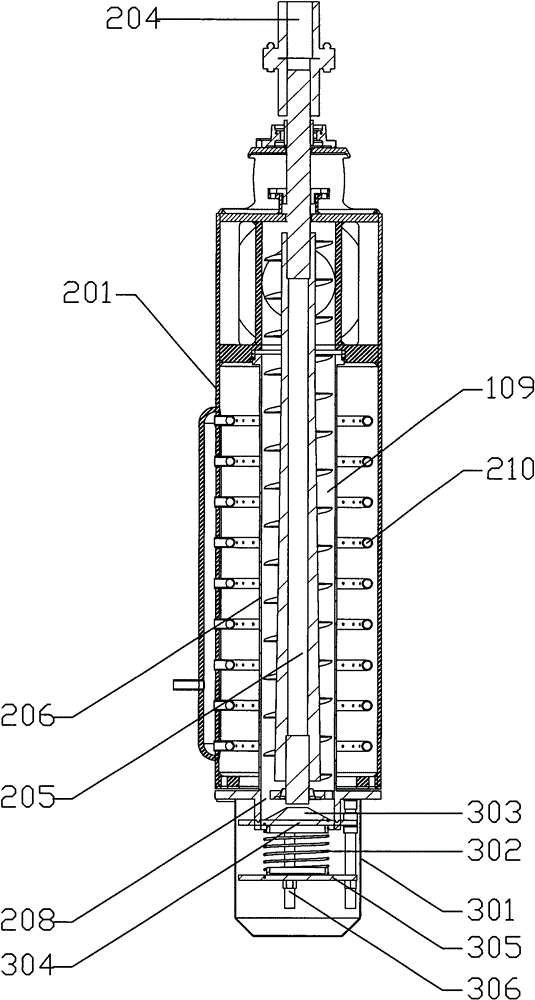

[0034] Such as Figure 1 ~ Figure 3As shown, the fully automatic continuous filter press filter unloading machine includes a filter device 10, the filter device 10 includes a cylindrical filter cartridge 101, the filter cartridge 101 is arranged perpendicular to the horizontal plane, and the top of the filter cartridge 101 is provided with a concave end cover 102, a first partition is tiled between the filter cartridge 101 and the end cover 102, a through hole is provided in the middle of the first partition, and a liquid inlet 103 is provided on the end cover 102, and the end cover 102 and the first partition A filter material storage box is formed between the plates; a first motor 104 is arranged above the end cover 102, and the output shaft of the first motor 104 is connected to a filter stirring shaft 105, and the filter stirring shaft 105 is driven by the first motor 104 to rotate , the filter stirring shaft 105 is located in the filter cartridge 101, the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com