Method for depositing an insulating material into a via

A technology of insulating material layer and conductive hole, applied in metal material coating process, circuit, electrical components and other directions, can solve the problem of unavailability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

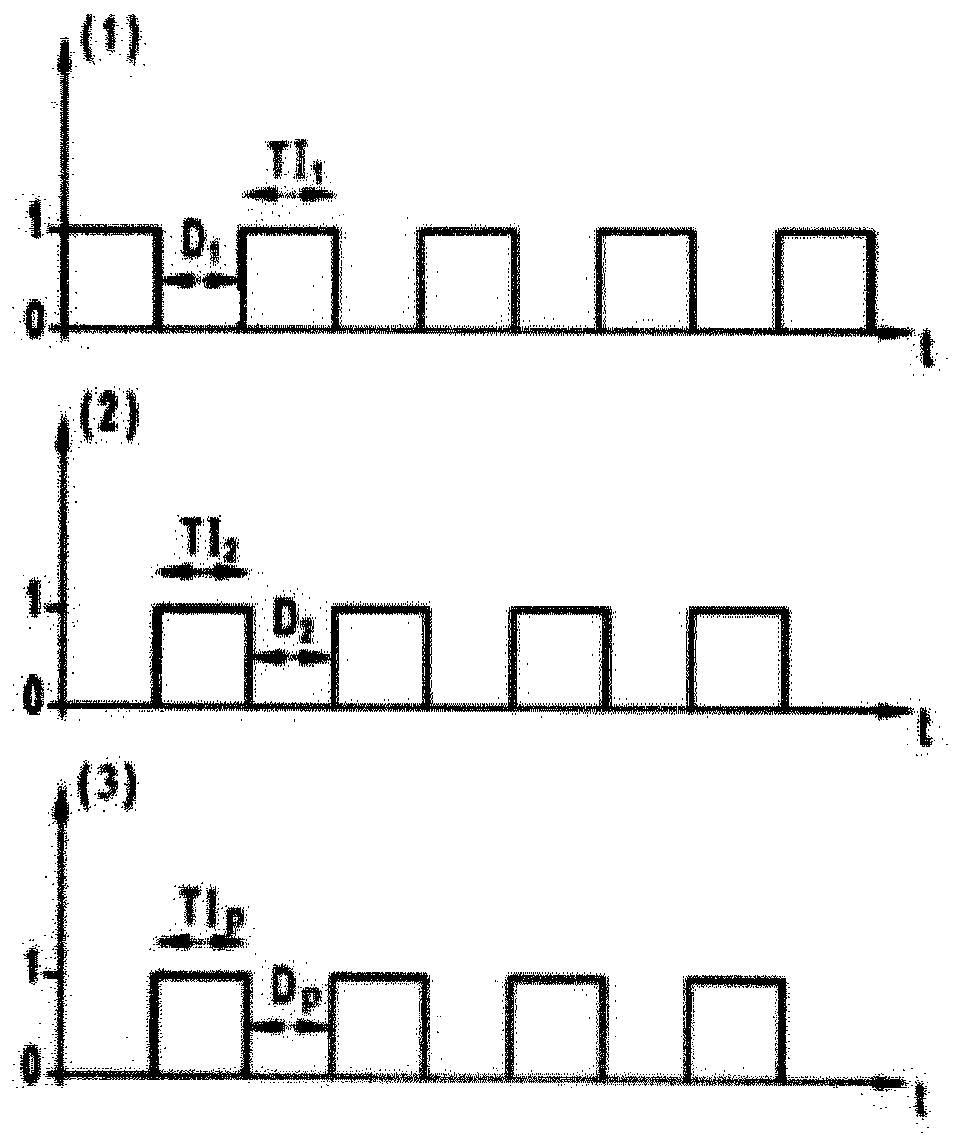

[0071] - the duration TI1 of one pulse of the first pulse sequence and / or the duration TI2 of one pulse of the second pulse sequence may be in the range of 0.02 s to 1 s, respectively;

[0072] - the time interval D1 between two pulses of the first pulse sequence and the time interval D2 between two pulses of the second pulse sequence may be in the range of 0.02s to 1s, respectively;

[0073] According to other implementations:

[0074] - the duration TI1 of one pulse of the first pulse sequence and the duration TI2 of one pulse of the second pulse sequence may be in the range of 1 s to 5 s, respectively;

[0075] - the time interval D1 between two pulses of the first pulse sequence and the time interval D2 between two pulses of the second pulse sequence may be in the range of 1 s to 10 s, respectively;

[0076] By definition, a plasma corresponds to an excited or ionized state of a gas, which further corresponds to the transfer of electrical energy from an electrical source ...

no. 1 approach

[0087] Similar to Sequence 1 and Sequence 2, the following terms are defined for Sequence 3 of the plasma as follows:

[0088] - Duration of one plasma pulse: TIp

[0089] - Time interval between two consecutive plasma pulses: Dp.

[0090] In the specific example of plasma sequence 3, the plasma pulse corresponds to the pulse of injection sequence 2 of the second chemical species. Thus, duration TIp corresponds to duration TI2, and time interval Dp corresponds to time interval D2.

[0091] E.g,

[0092] - the duration TIp of one plasma pulse may be in the range of 0.02s to 5s, and the time interval Dp between two plasma pulses may be in the range of 0.02s to 10s;

[0093] - the duration TIp of one plasma pulse may be in the range of 0.02s to 1s, and the time interval Dp between two plasma pulses may be in the range of 0.02s to 1s;

[0094] - the duration TIp of one plasma pulse may be in the range of 1 s to 5 s, and the time interval Dp between two plasma pulses may be in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com