Continuous drying device for polyester chips

A polyester chip and drying device technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problem of inability to dry, lack of mechanism to break up polyester chips, and affect drying efficiency question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

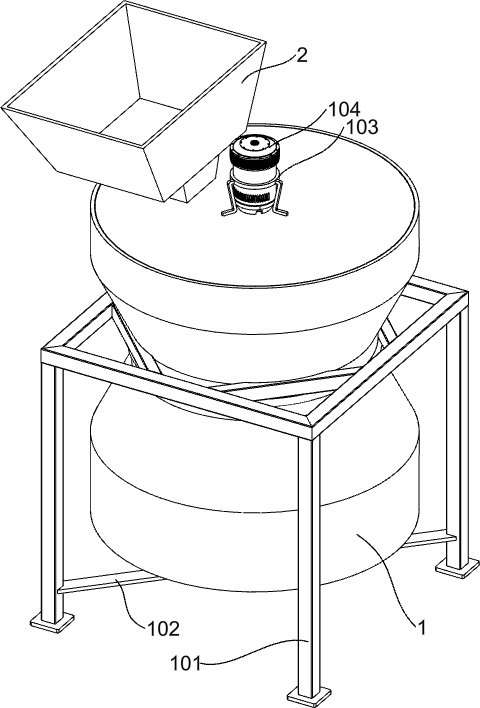

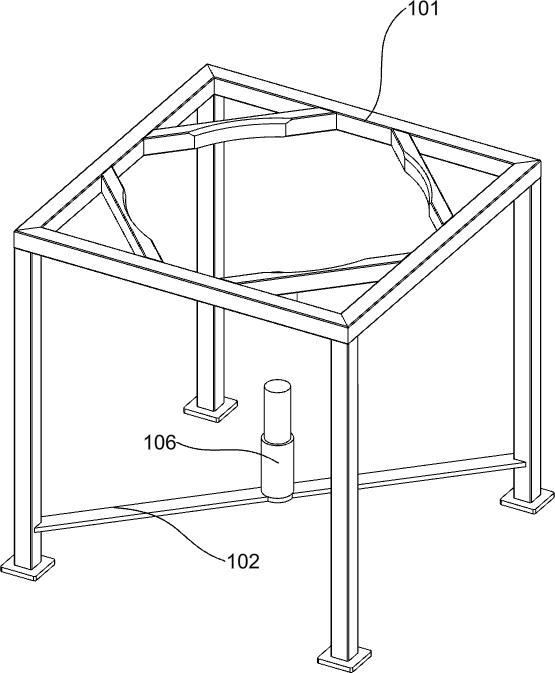

[0035] A continuous drying device for polyester chips, such as Figure 1-10 As shown, it includes a drying bin 1, a fixing frame 101, a fixing rod 102, a supporting frame 103, a power motor 104, a rotating shaft 105, a blanking frame 2 and a drum 201, and a drying bin 1 is fixedly installed in the fixing frame 101. The dry bin 1 is provided with a multi-layer drying structure. After multi-layer rolling and continuous drying treatment, the moisture inside the polyester chips will be completely dried. The bottom of the fixing frame 101 is fixedly connected with a fixing rod 102. The top of the drying bin 1 is The wall is provided with a support frame 103, a power motor 104 is installed in the support frame 103, a rotating shaft 105 is rotatably connected in the drying bin 1, the output shaft of the power motor 104 is connected with the rotating shaft 105, and the power motor 104 drives the drying bin 1 through the rotating shaft 105. The drying structure of each inner layer oper...

Embodiment 2

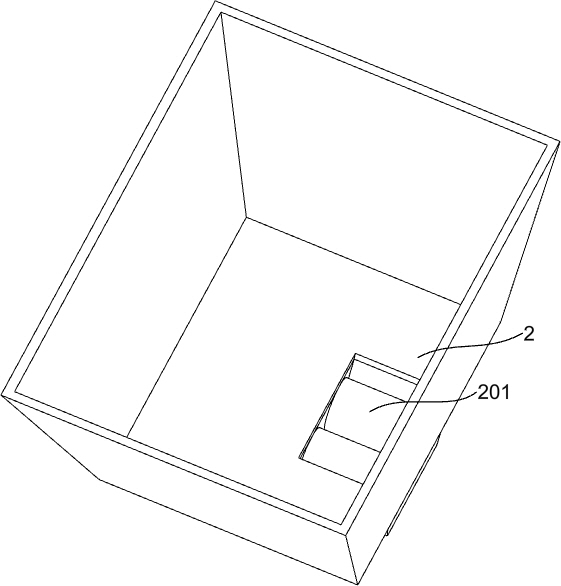

[0038] On the basis of Example 1, as Figure 4 As shown, it also includes a fixed feeding plate 3, a material pushing slant plate 301, a first connecting ring 302, a flattening stop rod 303 and a first connecting rod 304, and a fixed feeding plate 3 is fixed on the inner top of the drying bin 1, A first connecting ring 302 is rotatably connected to the top of the rotating shaft 105 , a first connecting rod 304 is fixed between the first connecting ring 302 and the drying chamber 1 , and a flattening block 303 is rotatably connected to the first connecting rod 304 , and the top of the rotating shaft 105 A pusher inclined plate 301 is fixed, and the side of the pusher inclined plate 301 in contact with the polyester chips is a vertical wall. The pusher inclined plate 301 pushes the polyester chips to move. The polyester chips will be spread out to a fixed thickness, and finally the polyester chips will be pushed to the rectangular through holes of the fixed feeder plate 3 by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com