Process for producing ethyl levulinate

A technology of ethyl levulinate and production process, which is applied in the directions of carboxylate preparation, organic chemistry, chemical instruments and methods, etc., can solve the problems of producing more waste water, low conversion rate, low output and the like, saving raw materials, simplifying Production process, the effect of improving product purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

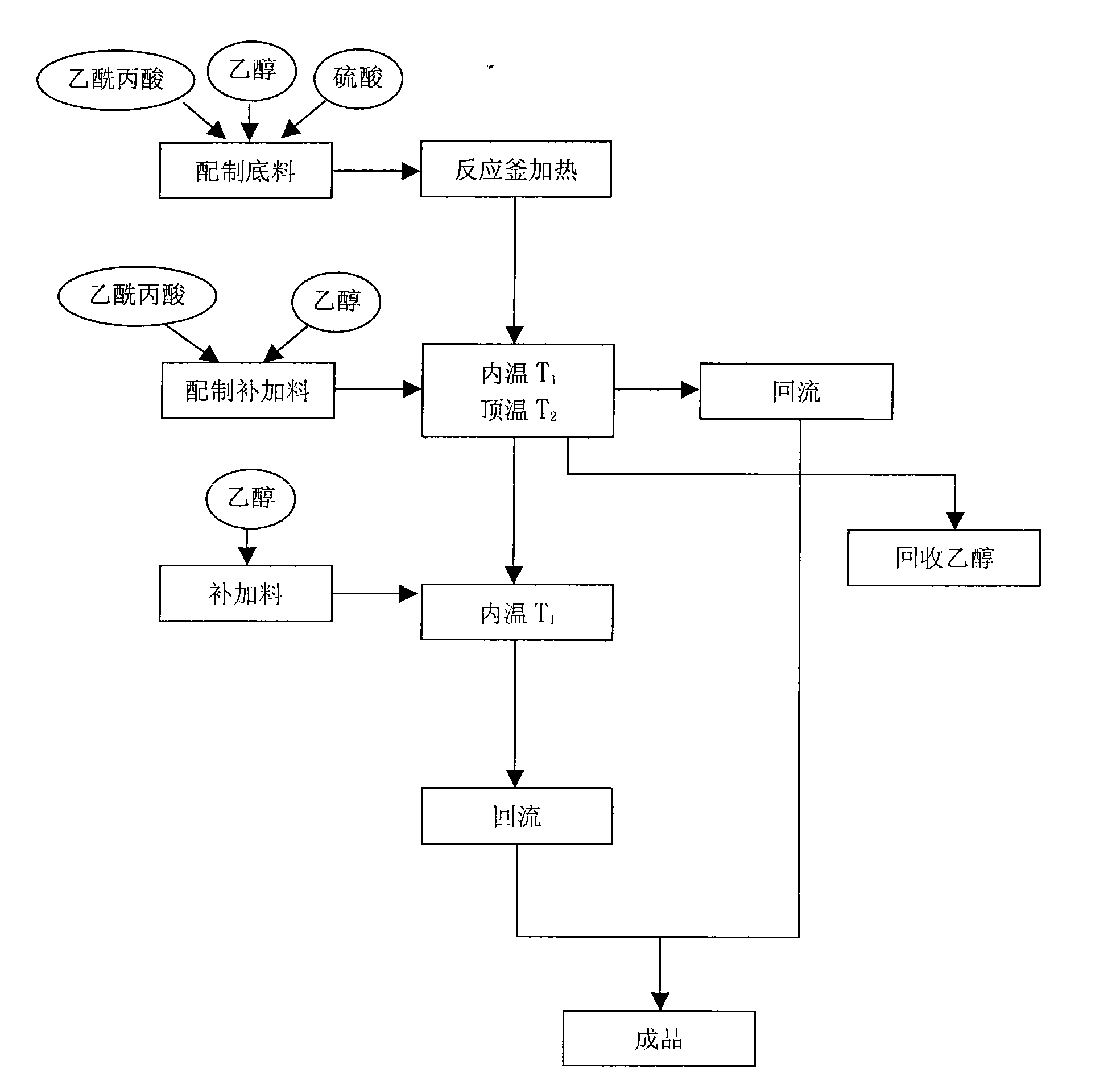

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] The esterification reaction is a typical reversible reaction. The reaction rate of the esterification reaction is inversely proportional to the concentration of the product and directly proportional to the concentration of the reactant. Therefore, in order to effectively promote the transfer of the reaction to the direction of the forward reaction, the best way is to lead the product out of the reaction system at any time. Reduce the concentration of the product while continuously feeding into the reaction pot to increase the concentration of the raw material, thereby reducing the concentration of ethyl levulinate that has been generated, and promoting the esterification reaction to continue in the direction of the positive reaction.

[0020] The present invention relates to a kind of ethyl levulinate production technique, it is characterized in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com