Method and apparatus for laser soldering

一种激光焊接、激光的技术,应用在激光焊接设备、送锡装置、辅助装置等方向,能够解决电子零部件4烧损、导电不良、外观不良等问题,达到消除烧损问题的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

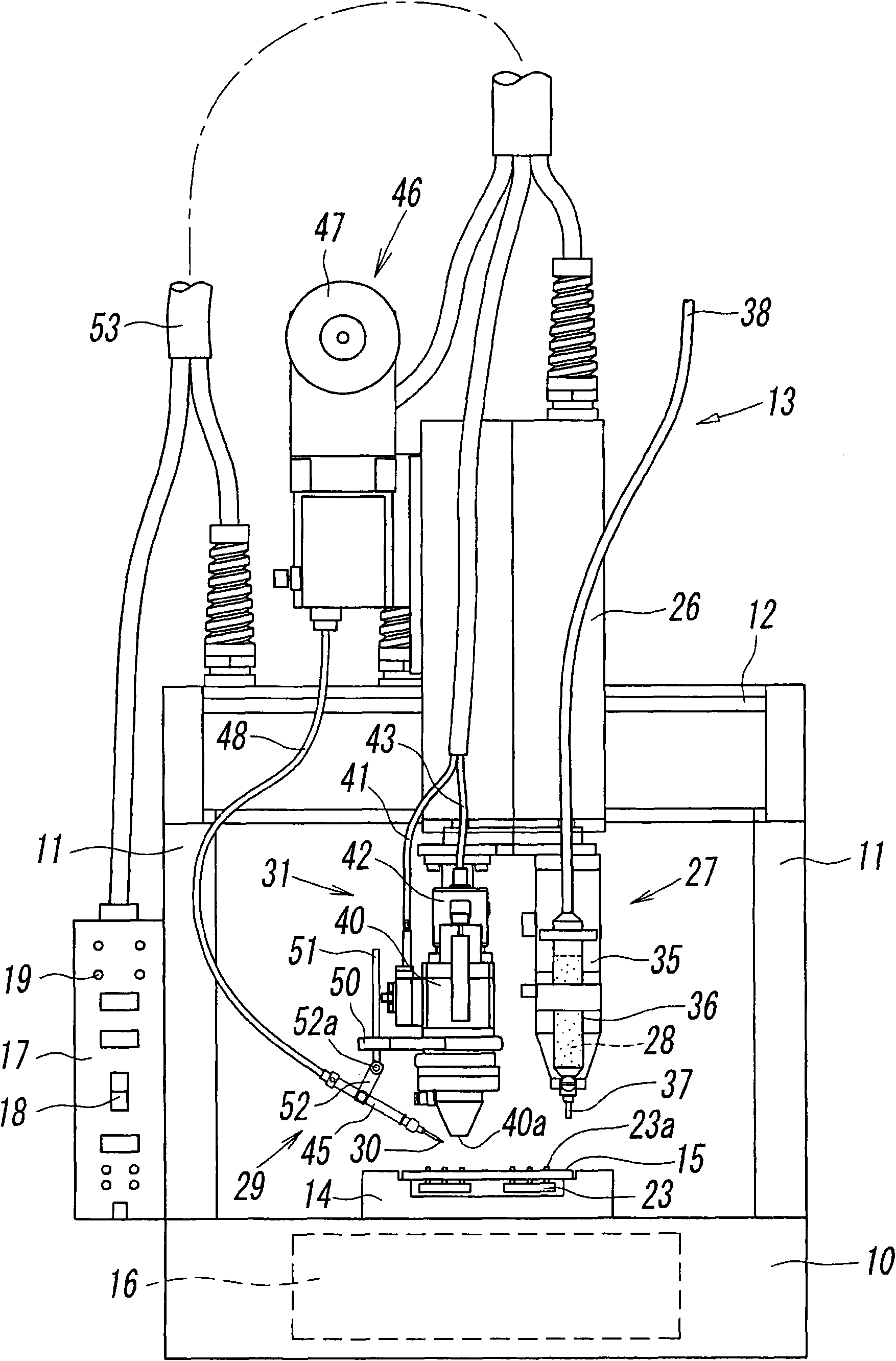

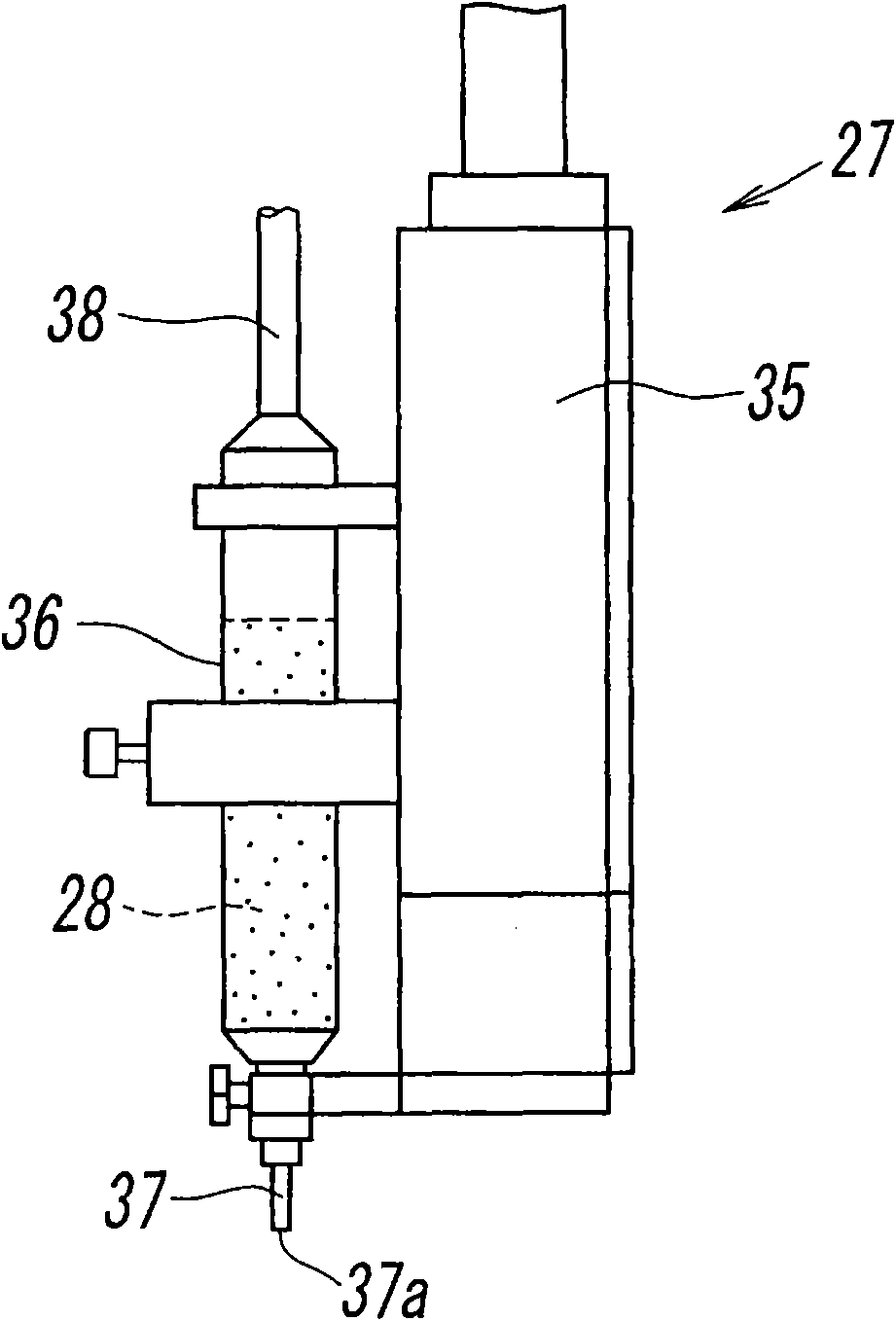

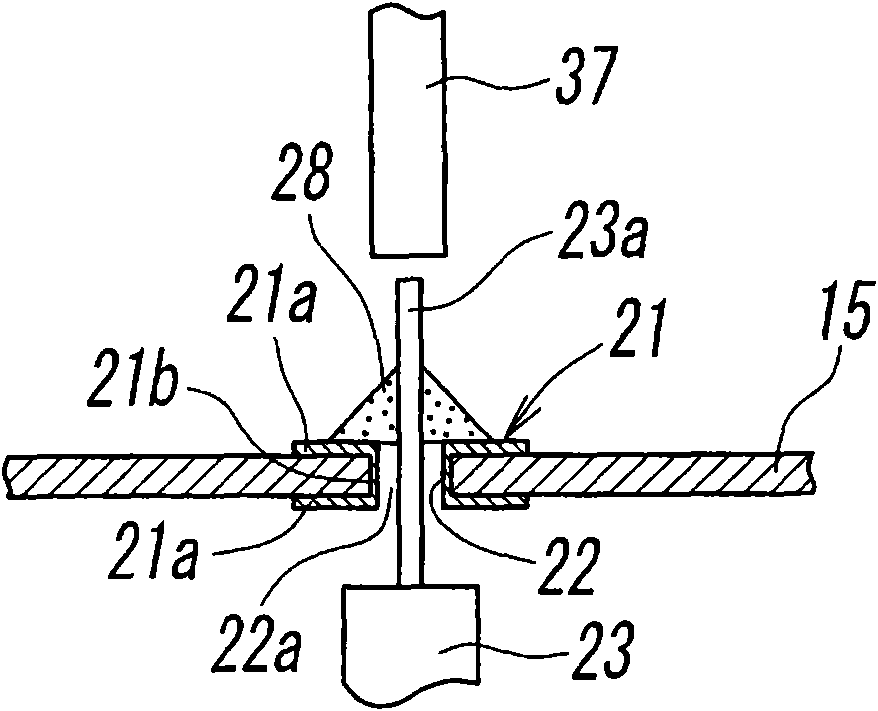

[0024] figure 1 It is a figure which shows one Embodiment of the laser welding apparatus of this invention. The laser welding device automatically performs welding according to the set program, including: a welding platform 10 with a rectangular top view shape; a pair of supporting columns 11 arranged at the left and right ends of the welding platform 10; horizontally spanning between the upper ends of the supporting columns 11 The guide rail 12; the welding head 13 that can move laterally (X direction) along the guide rail 12; the substrate support table 14 that is arranged on the described soldering station 10 for carrying the printed circuit board 15 as the welding object. The substrate supporting table 14 is operable to move in the front-back direction (Y direction) of the soldering table 10 .

[0025] Inside the soldering station 10, a control device 16 for controlling the action of the entire device is built in, and an operation panel 17 is provided on the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com