Collected waste heat recycling oven

An oven and waste heat technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of more energy consumption, safety hazards, complex structure, etc., to reduce the heating tube power and avoid safety Hidden dangers and the effect of avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

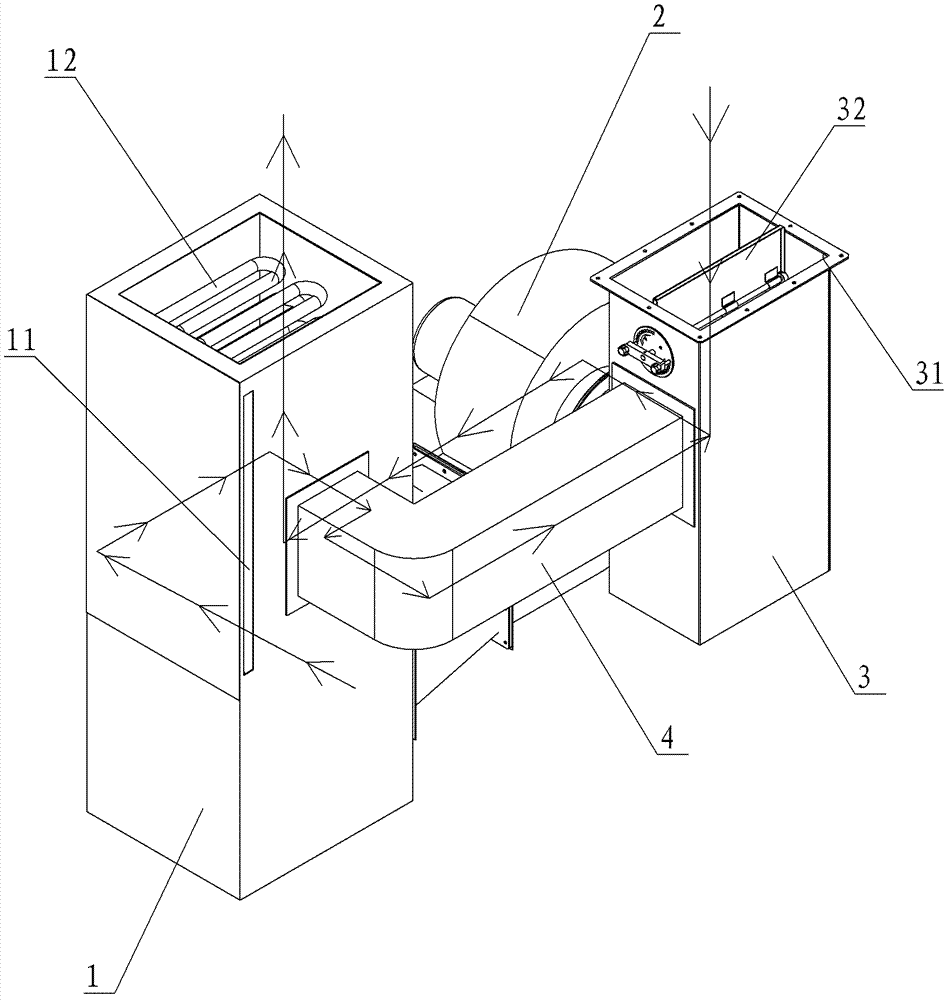

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

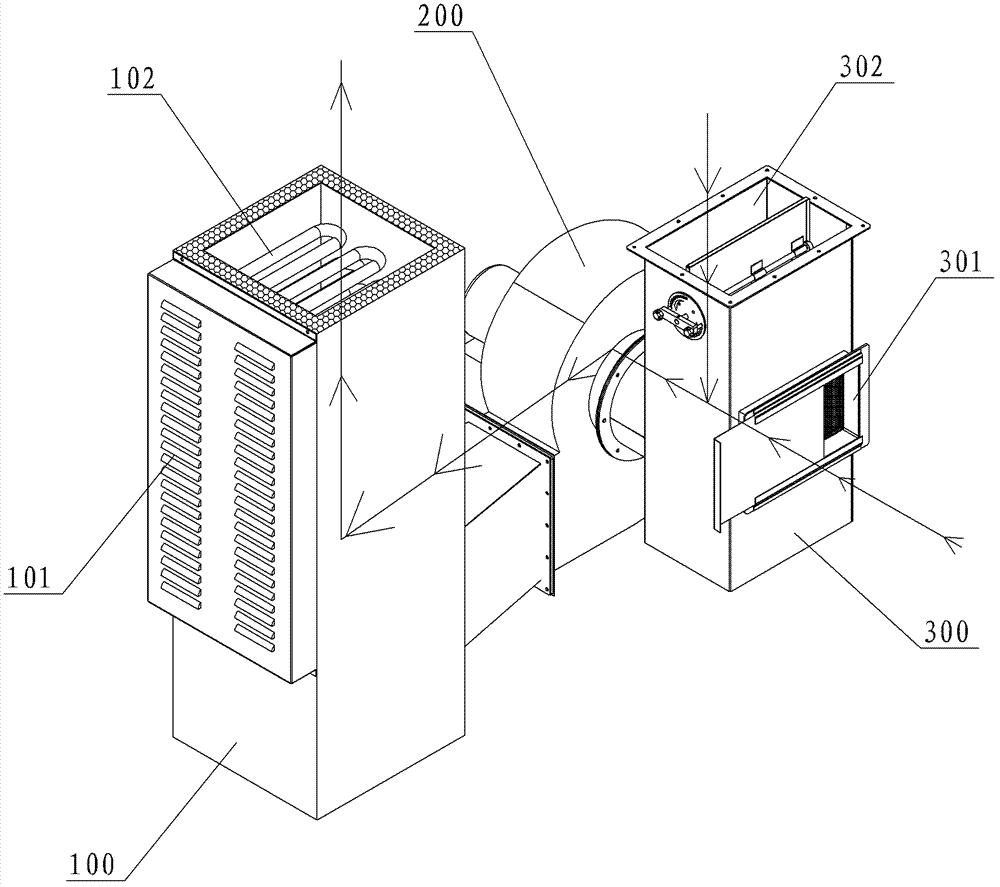

[0019] see image 3 as well as Figure 4 , The present invention relates to a recycling oven for waste heat collection, which includes a first box 1, a blower 2, a second box 3, a heating pipe 12 and a preheating air communication pipe 4.

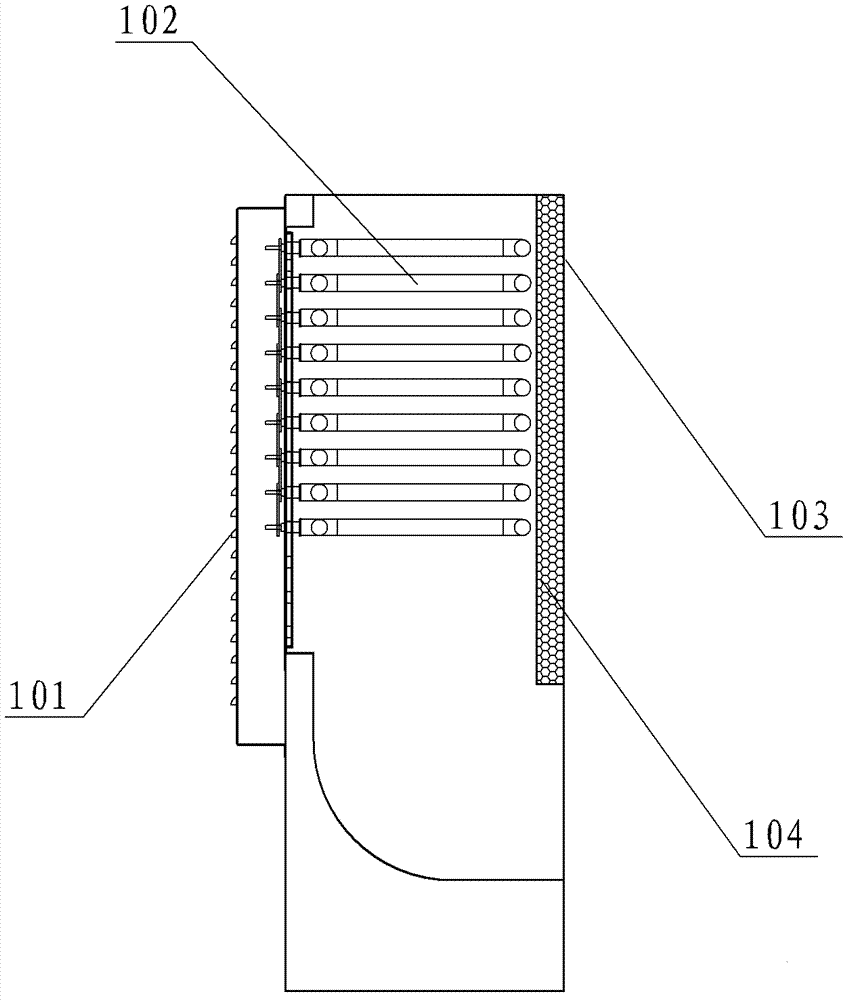

[0020] Wherein, the first box body 1 includes an inner container 13 and an outer container 14 . The inner bag 13 is hollow to form a first fluid channel 17, and a second fluid channel 15 is formed between the inner bag 13 and the outer bag 14. Considering the characteristics of the fluid, preferably, the second fluid channel 15 is formed by the inner bag. 13. The side walls of the outer bladder 14 are formed by airtight intervals. In addition, the inner tank 13 is also provided with a fluid inlet 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com