Can blocking rod, compression type garbage truck and using method of compression type garbage truck

A garbage truck and compression technology, which is applied in the direction of garbage receptacle, transportation and packaging, etc., can solve the problems that the garbage can cannot be blocked, the position of the bucket stop lever is difficult to determine, and the structure of the bucket stop lever cannot be adjusted, etc., so as to improve the anti-corrosion and Topcoat quality, reduced protective work, one-off assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

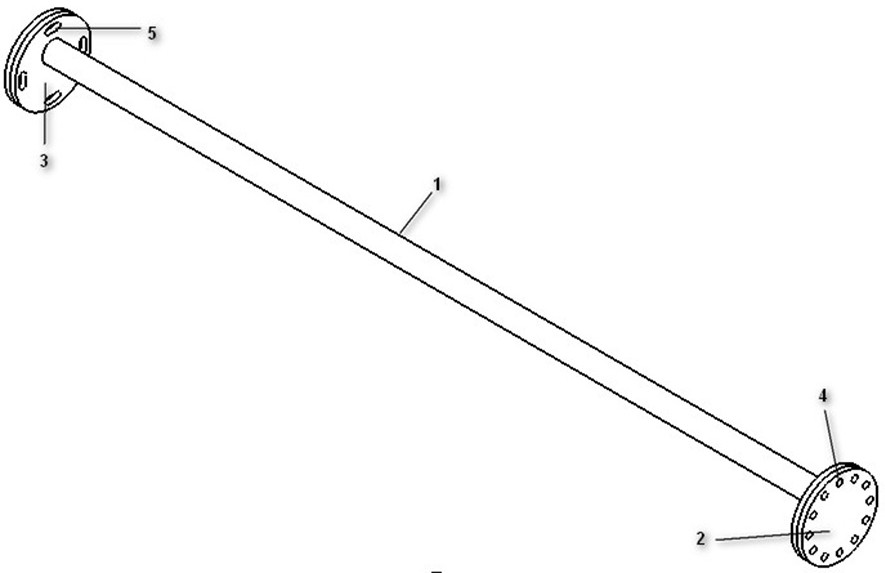

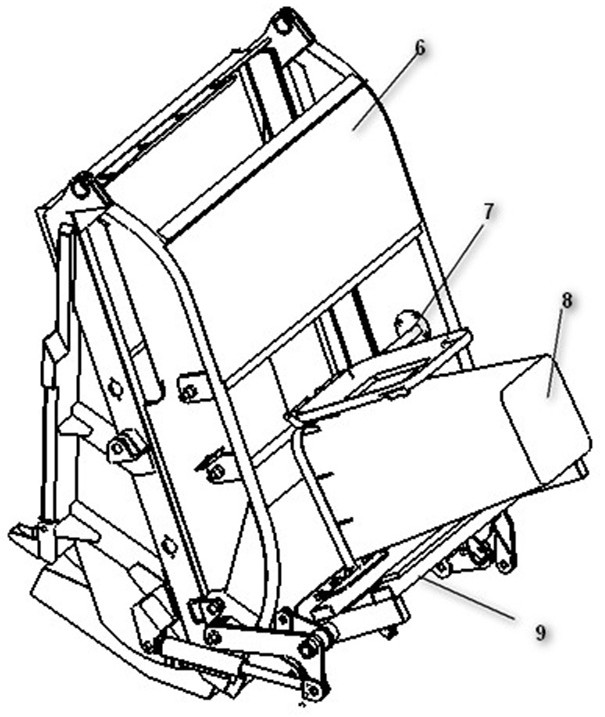

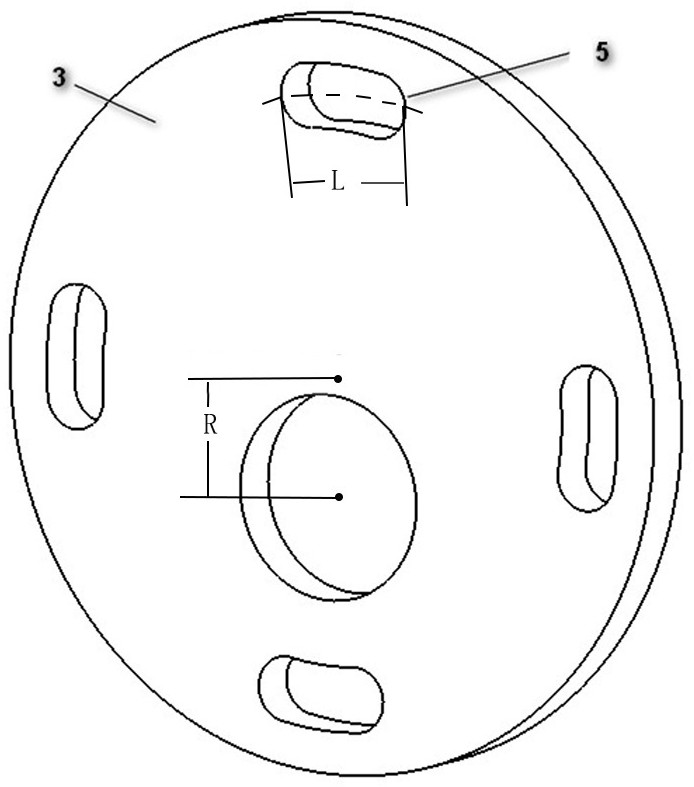

[0027] Such as figure 1 As shown, a barrel bar, comprising a barrel bar body 1 and two connecting plates 2 for being connected to a garbage truck filler 6, two ends of the barrel bar body 1 are respectively connected with reinforcing plates 3, The distance between the axis of the barrel rod body 1 and the center of the reinforcement plate 3 is the eccentric radius R, R>0; the connection plate 2 is provided with connection holes I4 at intervals along its circumference, and the reinforcement plate 3 is arranged along its circumference There are connecting holes II5 at intervals in the direction, the axial length L of the connecting hole II5 is greater than the axial length of the connecting hole I4, and a connecting piece (not shown in the figure) is fixed in the connecting hole I4 and the connecting hole II5 to connect The connecting plate 2 and the reinforcing plate 3 are fixed together. The structure of the reinforcing plate 3 is as image 3 As shown, the reinforcing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com