Flow-dividing regulation and storage system with spiral steps and pore plate drop well

A technology of falling wells and steps, which is applied in waterway systems, sewer systems, sewage removal, etc., can solve the problem of spiral ramp shafts and falling shafts with weak flood capacity, high maintenance costs, and high pressure on the surface of stilling wells, etc. It can reduce the burden of protection work, facilitate engineering construction, and prevent cavitation and cavitation erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] DETAILED DESCRIPTION OF THE INVENTION The specific embodiments of the present invention will be further described below with reference to the drawings and technical solutions.

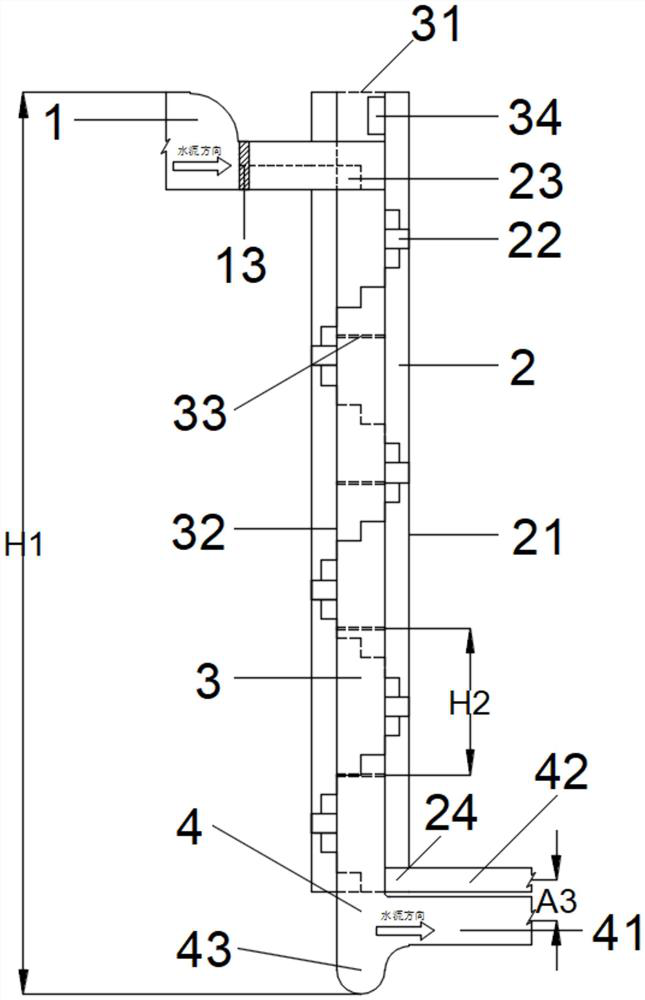

[0044] Such as figure 1 As shown, the shunting system of the spiral step and the hole plate decreased in the present invention includes an inlet pipe 1, a helical step shaft 2, a hole plate, a well 3, and a water port conduit 4.

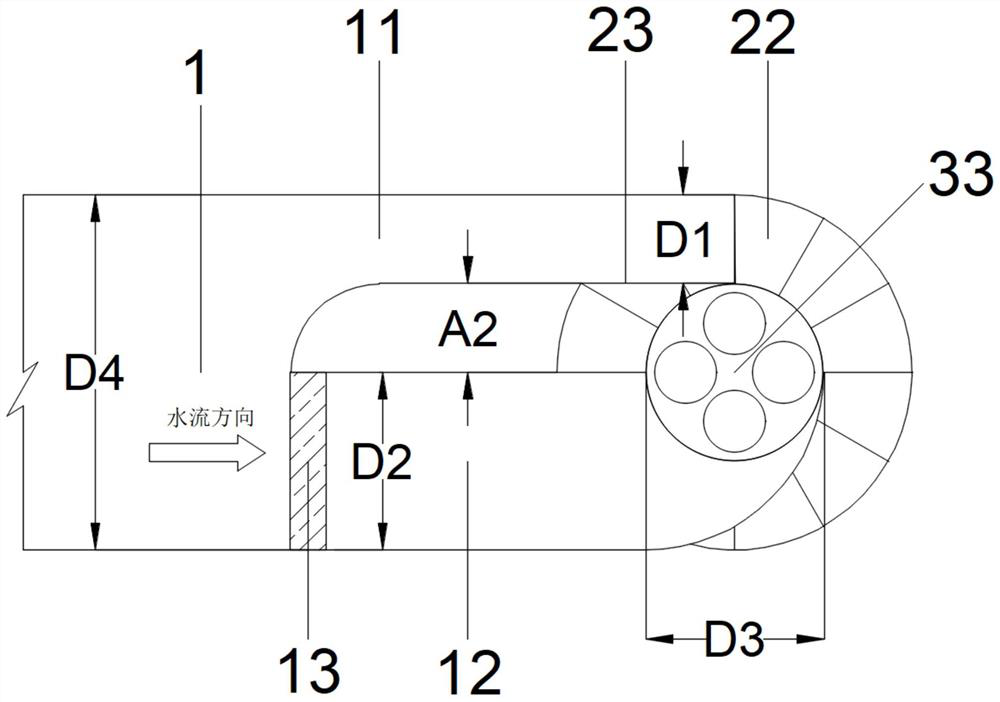

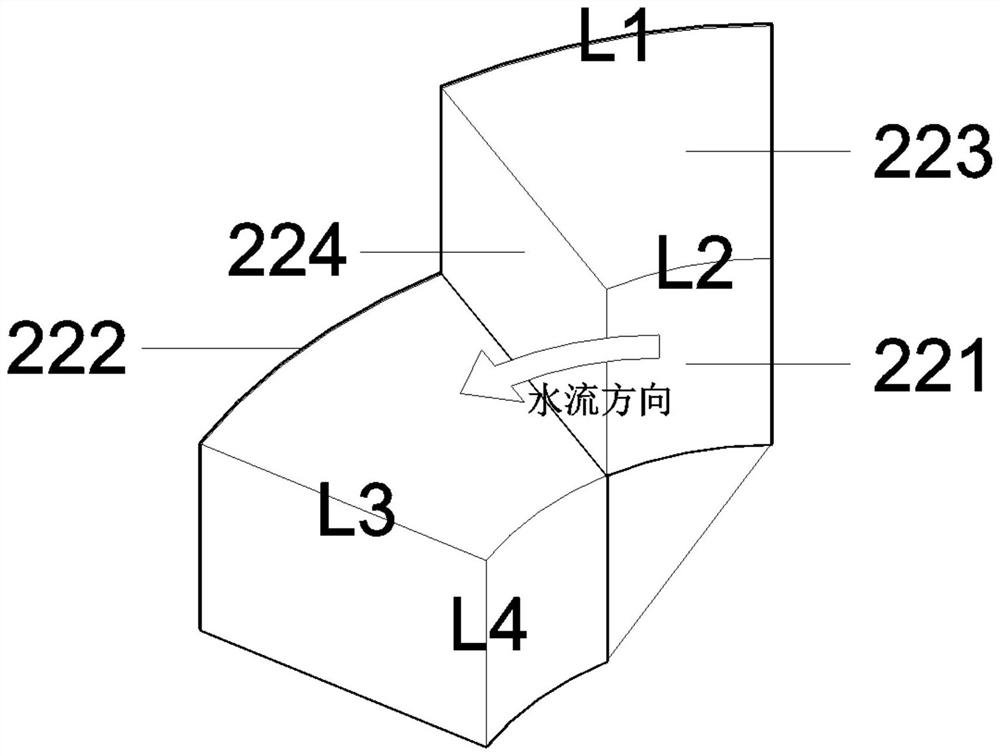

[0045] Such as Figure 2 ~ 4 As shown, the split storage system of the spiral step and the hole plate decreased wells includes an inlet pipe 1 (the spiral step shaft into the water port branch 11, the hole plate drops well into the water port pipe 12, the hydraulic self-control flap gate 13 ), A spiral step shaft 2 (spiral step shaft body 21, spiral step 22, inlet partition block 23, water outlet separator 24), a hole plate drop 3 (ventilator 31, hole plate dropping well body 32 , Well plate 33, ventilation inspection port 34) and two water port pipes 4 (spiral step shaft w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com