Measuring reflection piece support

A technology of reflectors and cartridges, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of being easily polluted by dust and sprayed grout, non-reusable brackets, and increased cost of observation materials, etc., to achieve guaranteed The effect of measuring accuracy and reliability, reducing the input of observation materials, and shortening the cycle time of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

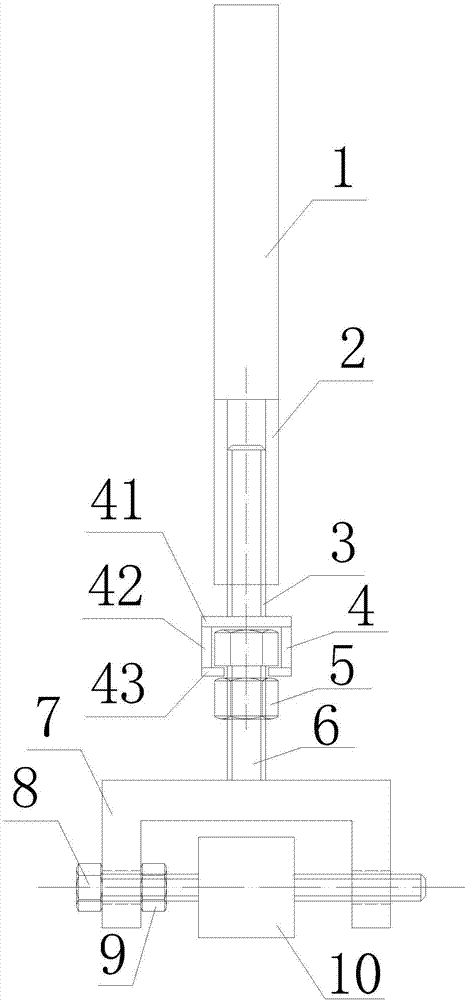

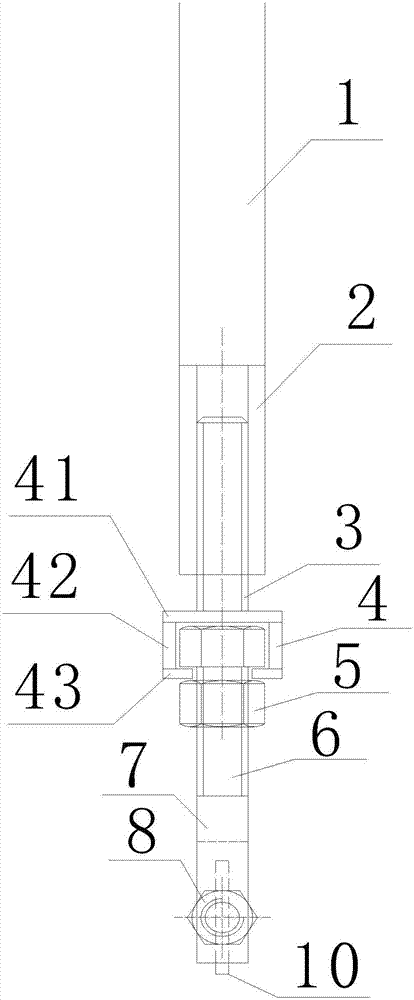

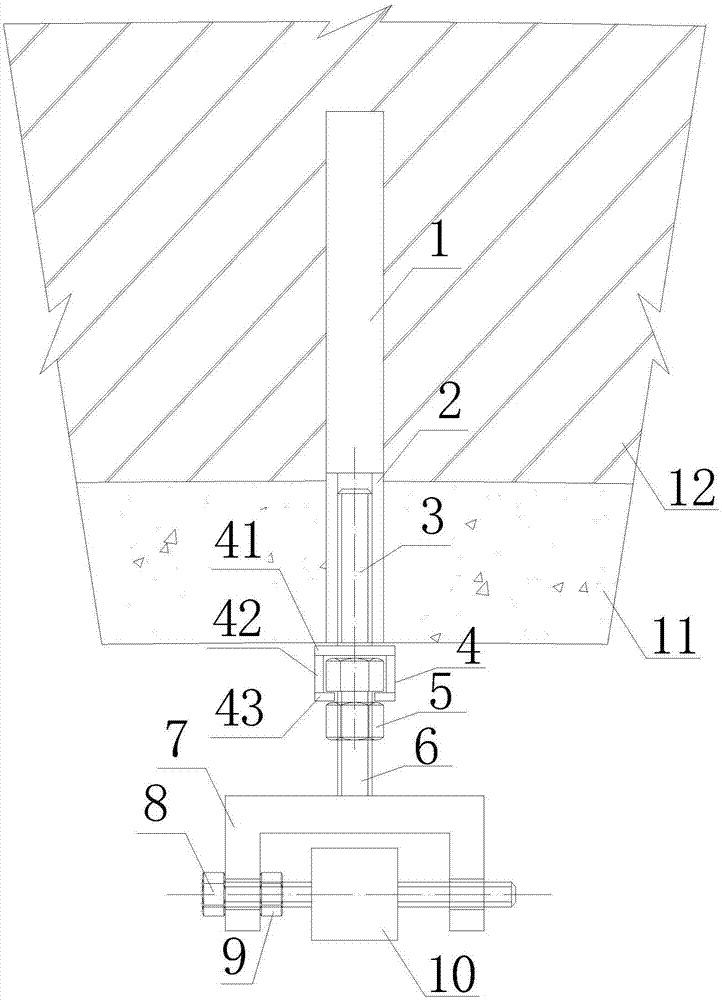

[0016] see Figure 1 ~ Figure 3 , the present invention includes an anchoring section and a movable section, the anchoring section is pre-embedded in the surrounding rock 12 and the primary support structure 11, includes an anchoring steel bar 1 and a sleeve 2, and the anchoring steel bar 1 and the sleeve 2 are welded; the movable section is a support The exposed part, the movable section can be disassembled and reused as a whole, the movable section includes the cartridge 4 and the U-shaped frame 7, the cartridge 4 includes the bottom 41, the wall 42 and the top 43, the bottom 41 of the cartridge and the sleeve of the anchoring section 2 Threaded connection, the central opening of the top 43 of the cartridge box is connected with the U-shaped frame 7 through the radially rotating bolt 6, specifically, the head of the radially rotating bolt 6 is buckled in the cartridge 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com