Concrete prefabricated panel, prefabricated building formed by same and construction method

A prefabricated wallboard and concrete technology, applied in building structures, buildings, building components, etc., can solve the problems of large on-site construction workload, small longitudinal circular hole size, large workload, etc., to reduce welding production and inspection work. volume, increase stability and shock resistance, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

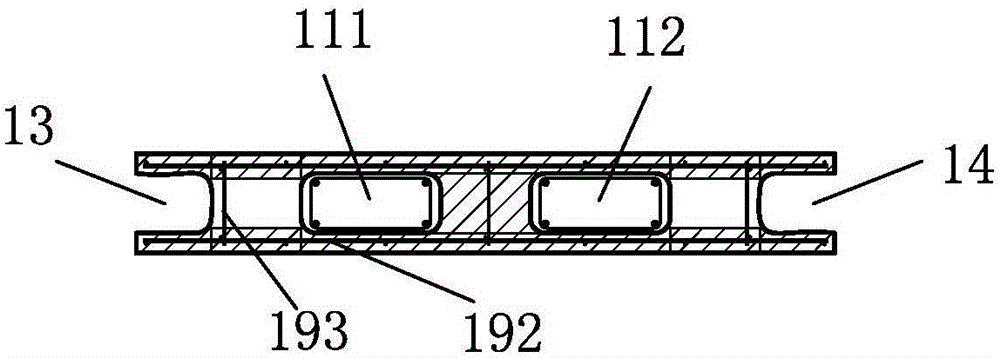

[0069] to combine Figure 1a-Figure 1e As shown, a concrete prefabricated wall panel is provided with two longitudinal holes 111, 112 inside the wall panel, and the vertical holes 111, 112 penetrate the wall panel up and down; the left side of the wall panel is provided with a plurality of transverse holes 121, and the inside of the wall panel is right. A plurality of transverse holes 122 are arranged on the side, and the transverse holes 121, 122 do not penetrate the wallboard left and right.

[0070] The size of the section parallel to the bottom surface of the wallboard in the longitudinal holes 111 and 112 is ≥200X100mm; the size of the section parallel to the side of the wallboard in the transverse holes 121 and 122 is ≥80X80mm; The left and right through grooves 15 are provided on the lower side of the wallboard with the left and right through grooves 16 along the width direction of the wallboard. The height of the grooves 15, 16 is 0-120mm.

[0071] The shape of the c...

Embodiment 2

[0082] to combine Figure 2a-Figure 2d As shown, a concrete prefabricated wall panel is provided with a vertical hole 21 inside the wall panel, and the vertical hole 21 penetrates the wall panel up and down; a plurality of horizontal holes 22 are provided on the left side of the wall panel, and the horizontal holes 22 do not penetrate left and right. wall panels.

[0083] The dimension of the section parallel to the bottom surface of the wallboard in the longitudinal hole 21 is ≥200X100mm; the dimension of the section parallel to the side of the wallboard in the transverse hole 22 is ≥80X80mm; Groove 25, the lower side of the wallboard is provided with the groove 26 that runs through left and right along the width direction of the wallboard. The height of the grooves 25, 26 is 0-120mm.

[0084]The shape of the section parallel to the side of the wallboard in the grooves 25 and 26 is an open trapezoid or rectangle; the wall vertical rib 291, the wall horizontal rib 292 and th...

Embodiment 3

[0094] combine Figure 3a and Figure 3b As shown, a concrete prefabricated wall panel is provided with a vertical hole 31 in the wall panel, and the vertical hole 31 penetrates the wall panel up and down; a plurality of horizontal holes 32 are provided in the left side of the wall panel, and the horizontal holes 32 do not pass through the left and right sides of the wall panel. wall panels.

[0095] The size of the section parallel to the bottom surface of the wallboard in the longitudinal hole 31 is ≥200X100mm; the size of the section parallel to the side of the wallboard in the transverse hole 32 is ≥80X80mm; Groove; the height of the groove is 0-120mm.

[0096] The shape of the section in the groove parallel to the side of the wall panel is an open trapezoid or rectangle; the wall vertical rib 391, the wall horizontal rib 392 and the wall tension rib are respectively distributed along the height, width and thickness directions of the wall panel. 393, the wall vertical r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com