Carbon dioxide automatic full position welding method for small bore pipes

An automatic welding and carbon dioxide technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as low welding efficiency and affecting welding quality, and achieve high pass rate, improved welding quality, and stable welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is mainly aimed at the automatic welding of pipelines below DN500. During the welding process of small-diameter pipelines, it is necessary to realize 360° (full position) CO welding of pipelines. 2 Gas shielded automatic welding is quite difficult.

[0046] A kind of carbon dioxide all-position automatic welding method of small diameter pipeline, it comprises an automatic welding machine, and this method comprises the following steps:

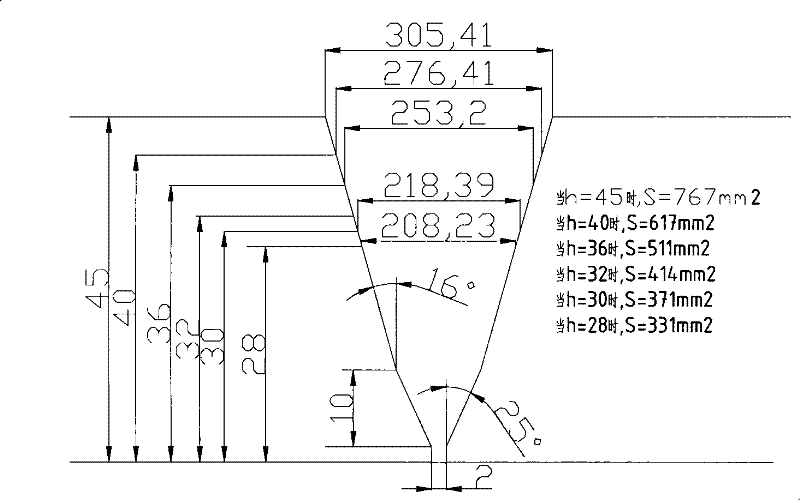

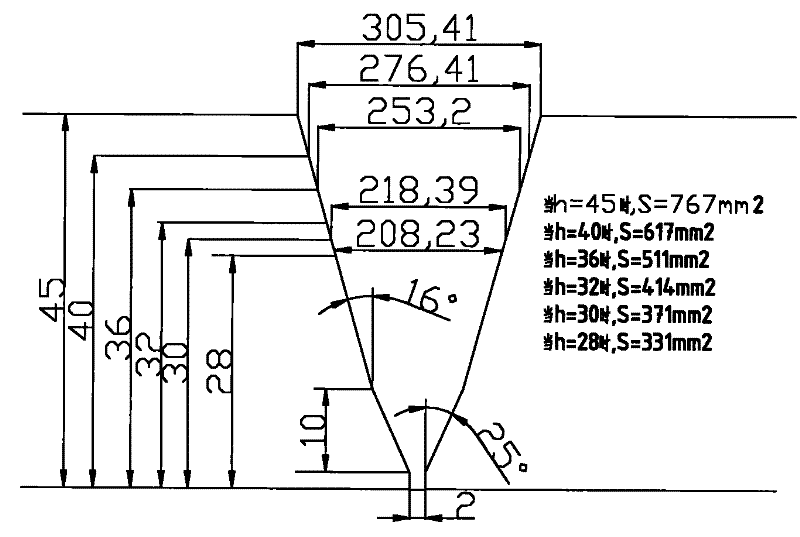

[0047] Welding groove preparation steps: automatic welding The welding groove is processed by mechanical method; when the pipe wall thickness is less than 28mm, the "V" groove is used; when the pipe wall thickness is greater than 28mm, the welding groove adopts the opening with the depth increasing jumping form (see figure 1 );

[0048] Pipeline assembly and spot-fixing steps: manual tungsten argon arc welding is used to spot-fix the pipeline, and the spot-fixing gap is 2.5-3mm;

[0049] Pipeline back cover weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com