Eggshell type Pd catalyst prepared by reaction deposition method

A technology of eggshell type and deposition method, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problem of high solvent cost, unfavorable industrialization, and carrier requirements Harsh and other problems, to achieve the effect of fewer influencing factors, easy industrialization, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

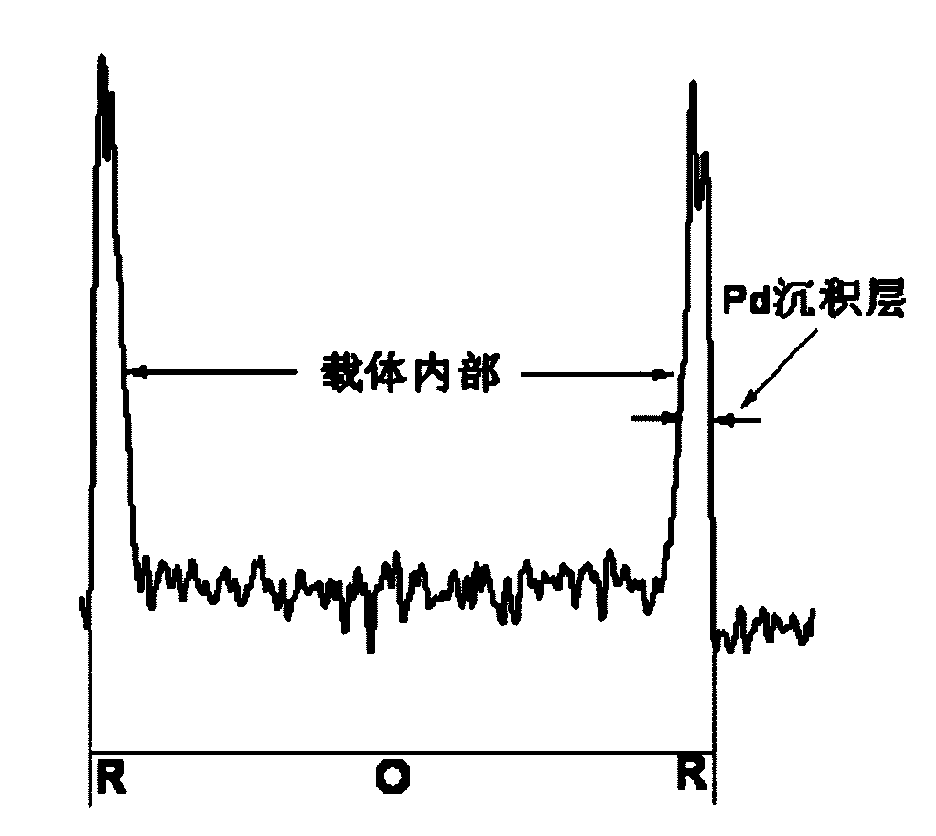

[0020] Weigh 0.0186gPdCl 2 , Measure the ethanol solution (25mL ethanol + 1mL deionized water), put it into a 50mL round bottom reaction bottle, and then add 2.0g of SiO2 calcined in air at 500°C 2 -Al 2 o 3 Carrier, feed CO to react, the flow rate is 26mL / min, and vigorously stir at room temperature. After two hours of reaction, adjust the CO flow rate below 5 mL / min and keep the reaction under CO atmosphere for 3 days. After the reaction is completed, the carrier is filtered out, washed with ethanol for more than 3 times, and dried in an Ar atmosphere to obtain eggshell-type Pd / SiO 2 -Al 2 o 3 catalyst. ICP results show that the mass percentage of metal Pd is 0.20%. The EPMA characterization result of gained eggshell type Pd catalyst is as follows figure 1 shown.

Embodiment 2

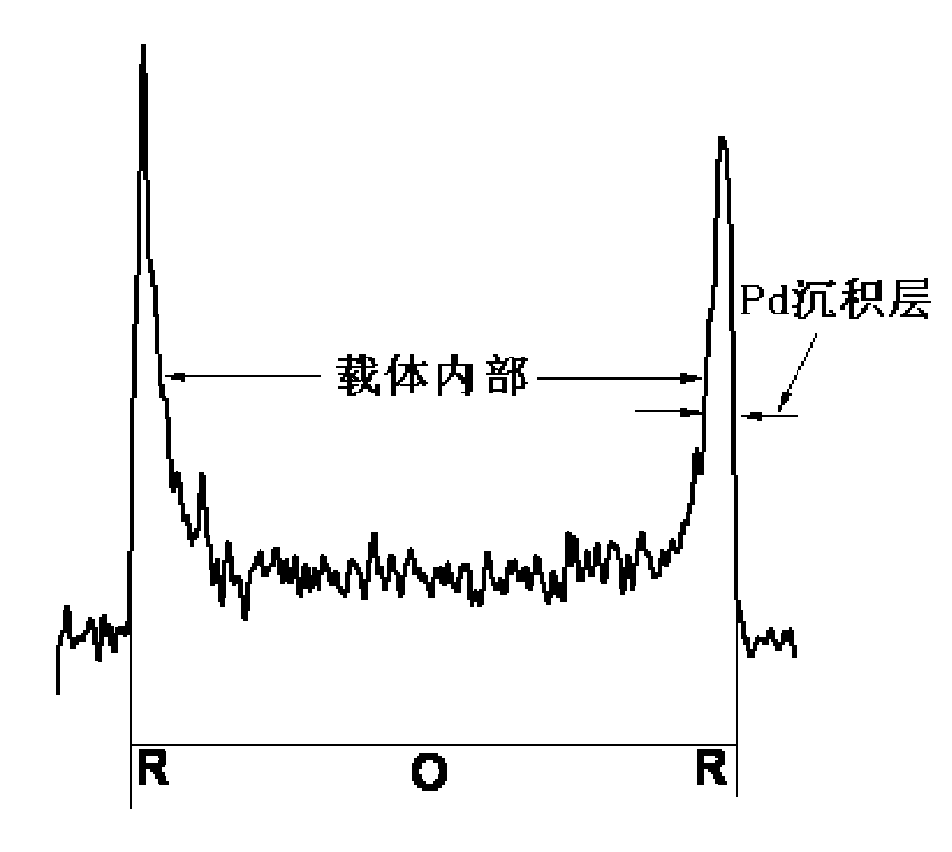

[0022] Weigh 0.0505gPdCl 2 , Measure the ethanol solution (25mL ethanol + 1mL deionized water), put it into a 50mL round bottom reaction bottle, and then add 2.0g of SiO2 calcined in 500°C air 2 -Al 2 o 3 Carrier, feed CO to react, the flow rate is 26mL / min, and vigorously stir at room temperature. After two hours of reaction, adjust the CO flow rate below 5 mL / min and keep the reaction under CO atmosphere for 3 days. After the reaction is completed, the carrier is filtered out, washed with ethanol for more than 3 times, and dried in an Ar atmosphere to obtain eggshell-type Pd / SiO 2 -Al 2 o 3 catalyst. ICP results showed that the mass percentage of metal Pd was 0.23%. The EPMA characterization results of eggshell-type Pd catalysts are as follows: figure 2 .

Embodiment 3

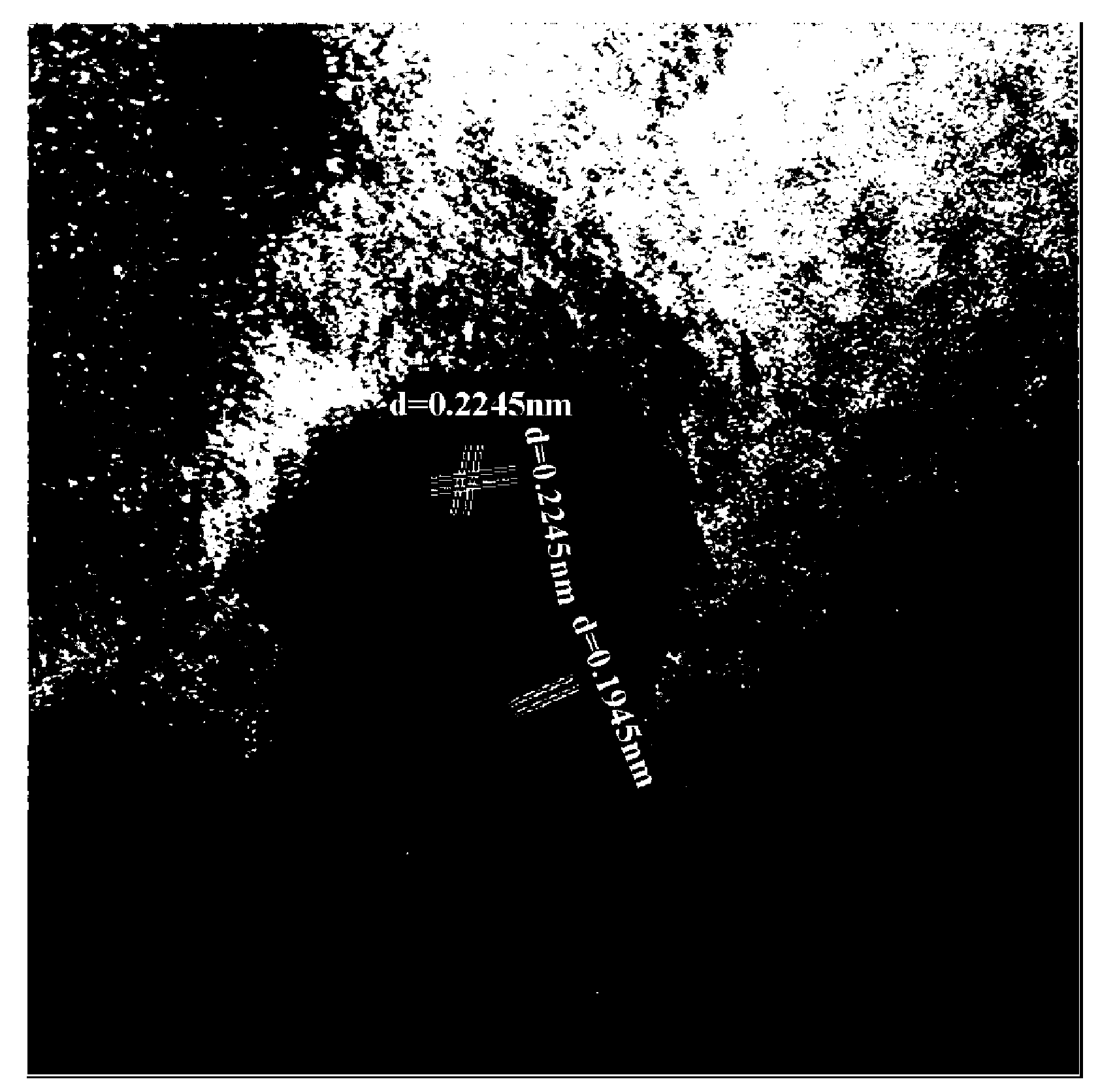

[0024] Weigh 0.1302gPdCl 2 , Measure the ethanol solution (25mL ethanol + 1mL deionized water), put it into a 50mL round bottom reaction bottle, and then add 2.0g of SiO2 calcined in 500°C air 2 -Al 2 o 3 Carrier, feed CO to react, the flow rate is 26mL / min, and vigorously stir at room temperature. After two hours of reaction, adjust the CO flow rate below 5 mL / min and keep the reaction under CO atmosphere for 3 days. After the reaction is completed, the carrier is filtered out, washed with ethanol for more than 3 times, and dried in an Ar atmosphere to obtain eggshell-type Pd / SiO 2 -Al 2 o 3 catalyst. ICP results showed that the mass percentage of metal Pd was 0.39%. The transmission electron micrograph of the Pd particle on the gained eggshell catalyst is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com