High temperature superconducting magnetic system protected by high heat capacity materials

A high-temperature superconducting, high-heat-capacity technology, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problem that the magnet is not installed with a low-temperature container, the magnet is difficult to run out of the refrigerator, and the high-heat-capacity cold storage material cannot be maintained. Magnet temperature and other issues, to achieve the effect of extending offline operation time, improving heat exchange efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

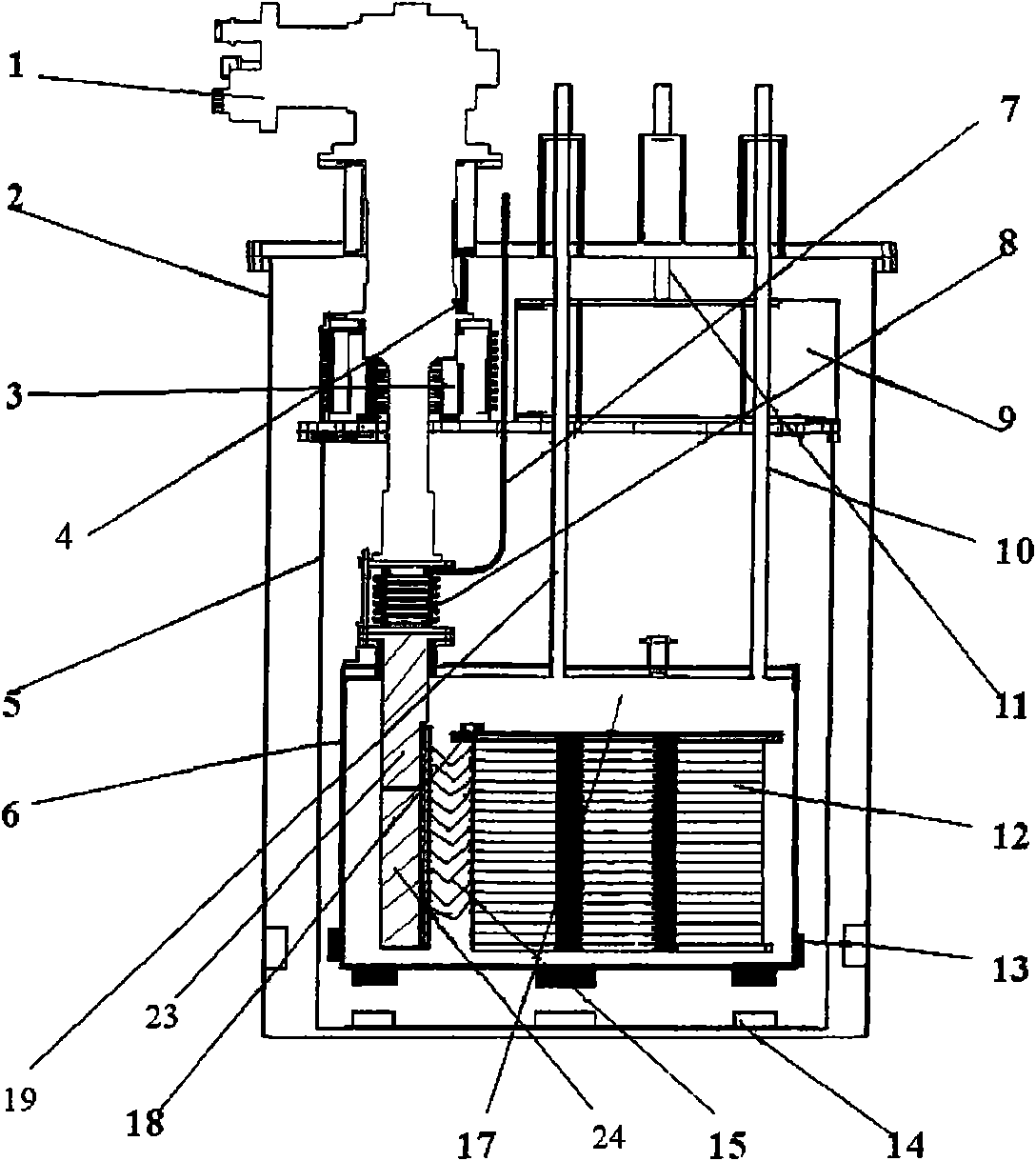

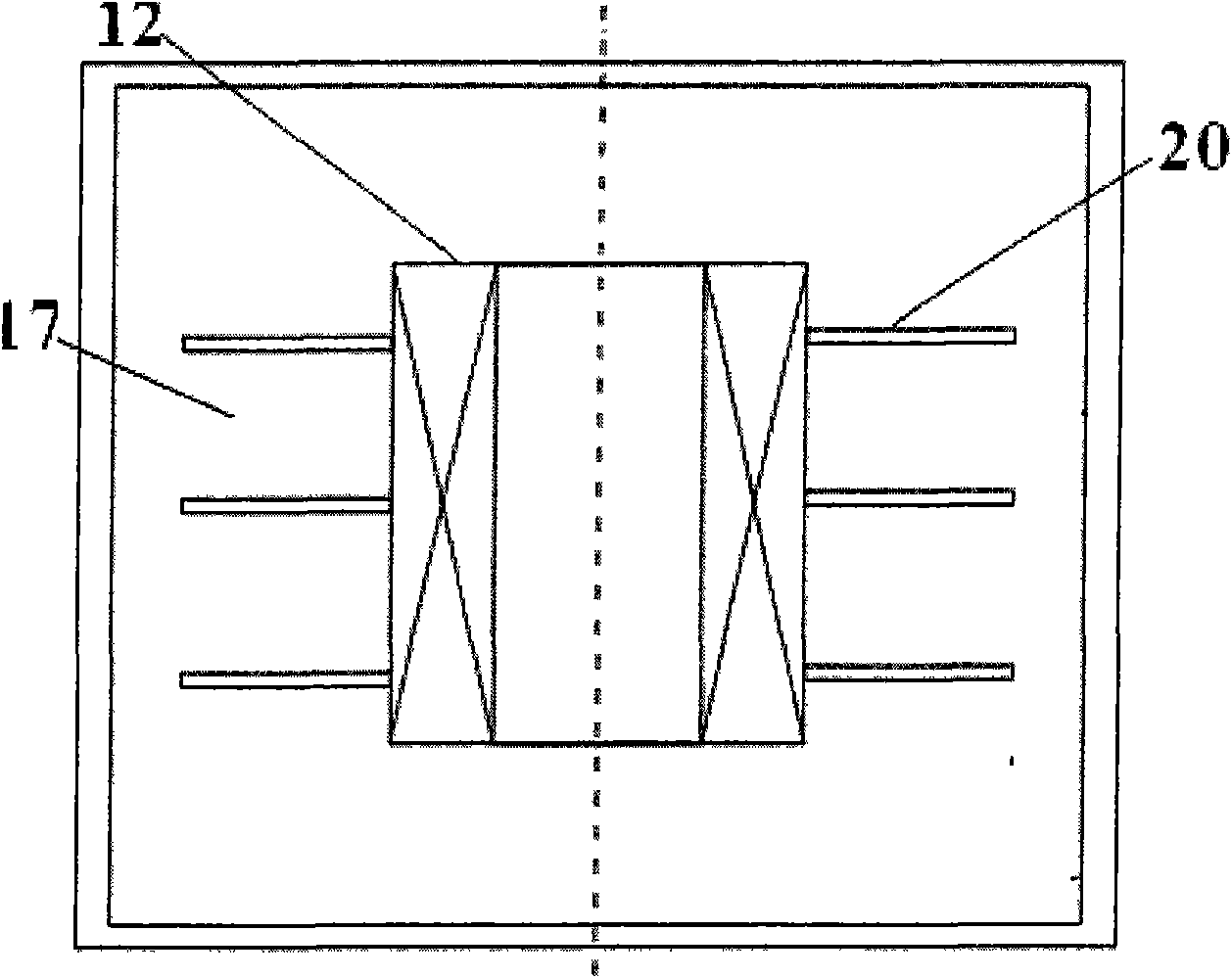

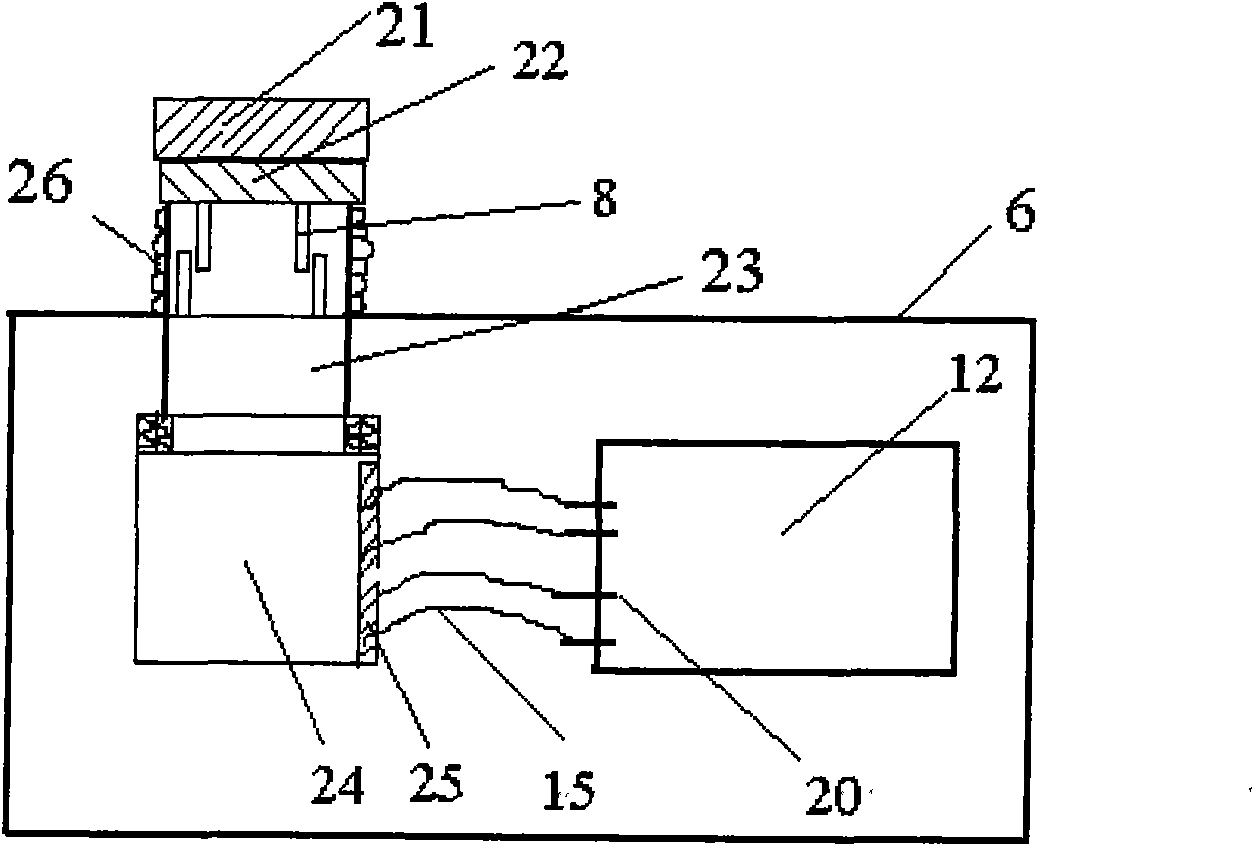

[0017] Such as figure 1 As shown, the refrigerator 1 is installed in the vacuum container 2 , and the primary cold head of the refrigerator 1 is connected with the cold shield 5 of the vacuum container 2 through the heat pipe 3 . The secondary cold head of the refrigerator 1 is connected to the low-temperature container 6 through the heat pipe 8, and the first cold-conducting copper rod 23 and the second cold-conducting copper rod 24 are connected to the high-temperature superconducting magnet 12 through the cold-conducting sheet 15. The cooling capacity required for cooling the high temperature superconducting coil 12 is provided as the high heat capacity cold storage material 17 . The cryogenic container 6 is connected with the outside world through a transfusion tube 10 . The high temperature superconducting magnet 12 is connected to the outside wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com