Method for preparing methyl acetate by carbonylating dimethyl ether

A technology for methyl acetate and dimethyl ether, which is applied in the field of preparing methyl acetate by carbonylation of dimethyl ether, can solve problems such as rapid catalyst deactivation, and achieve the effects of inhibiting carbon deposition, maintaining stable activity and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

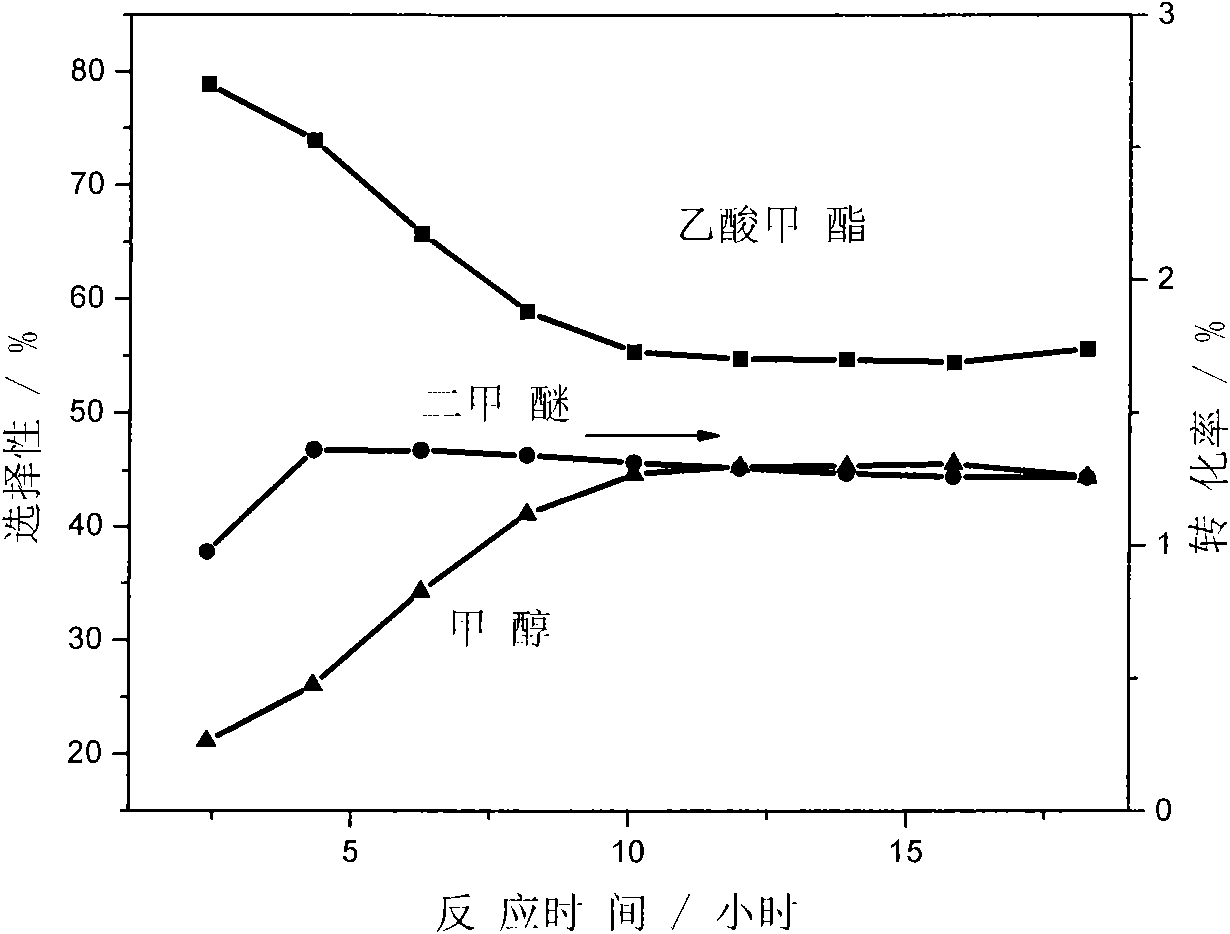

Embodiment 1

[0030] Add 100g NaMOR (Si / Al=5.6) to 1.5L, 1mol / L NH 4 NO 3 solution, kept at 90°C for 3 hours, then filtered, washed with 1L deionized water, and dried. Repeat the above exchange process 3 times. After the last exchange, it was dried at 110° C. for 12 hours, and then calcined at 500° C. for 6 hours in an air atmosphere in a muffle furnace to obtain a powdered catalyst. A part of the powder sample was pressed into flakes, pulverized, sieved to 40-60 mesh, used for activity test, and recorded as #1 catalyst.

Embodiment 2

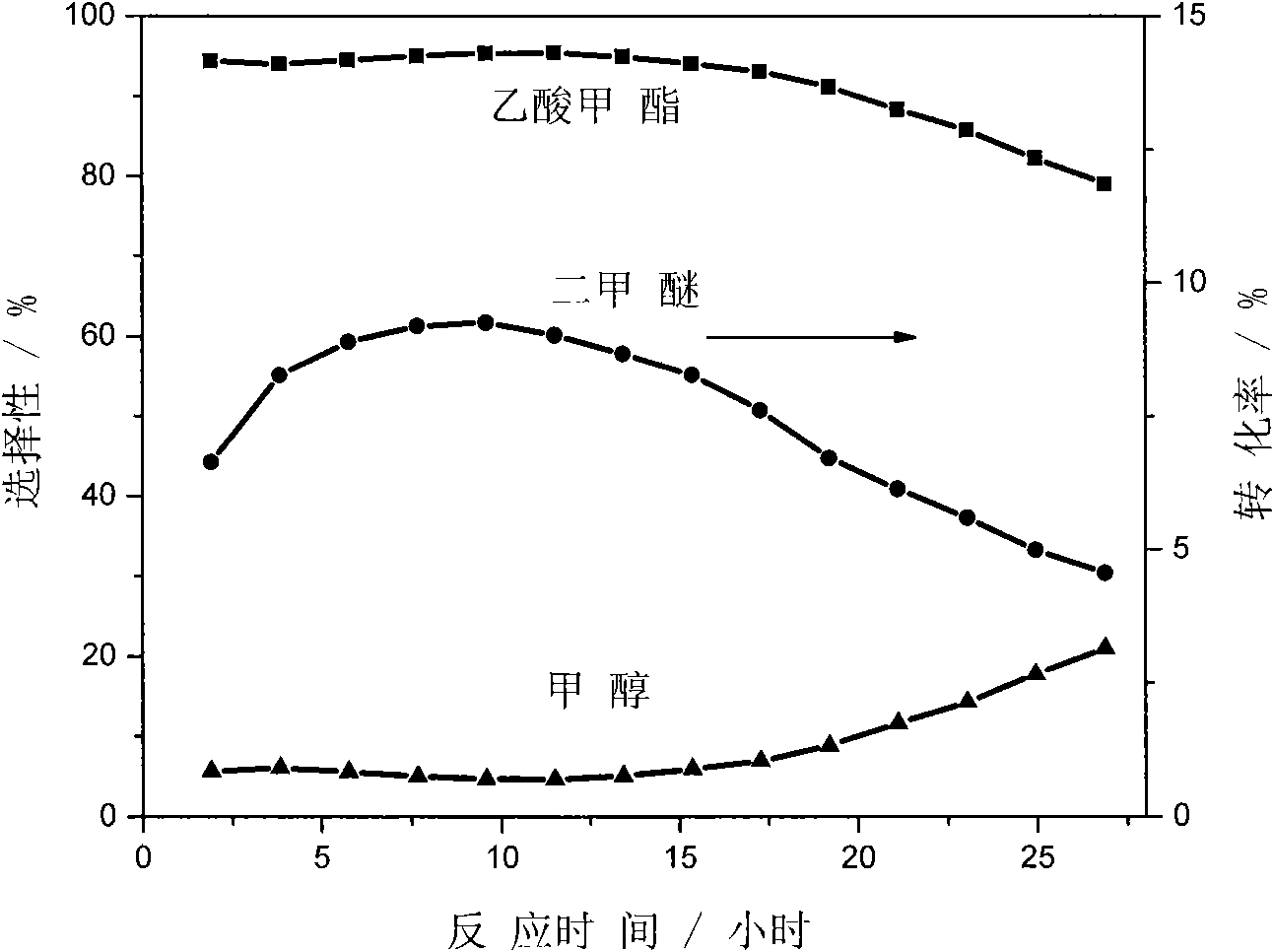

[0032] Add 10g #1 catalyst to 300ml, 2mol / L HNO 3 The solution was treated at 80°C for 10 hours under vigorous stirring. Then it is filtered, washed with 2L of deionized water, dried at 110°C for 12 hours, and baked in a muffle furnace at 500°C for 6 hours. A part of the powder sample was pressed into flakes, crushed, sieved to 40-60 mesh, and used for activity test, which was recorded as #2 catalyst.

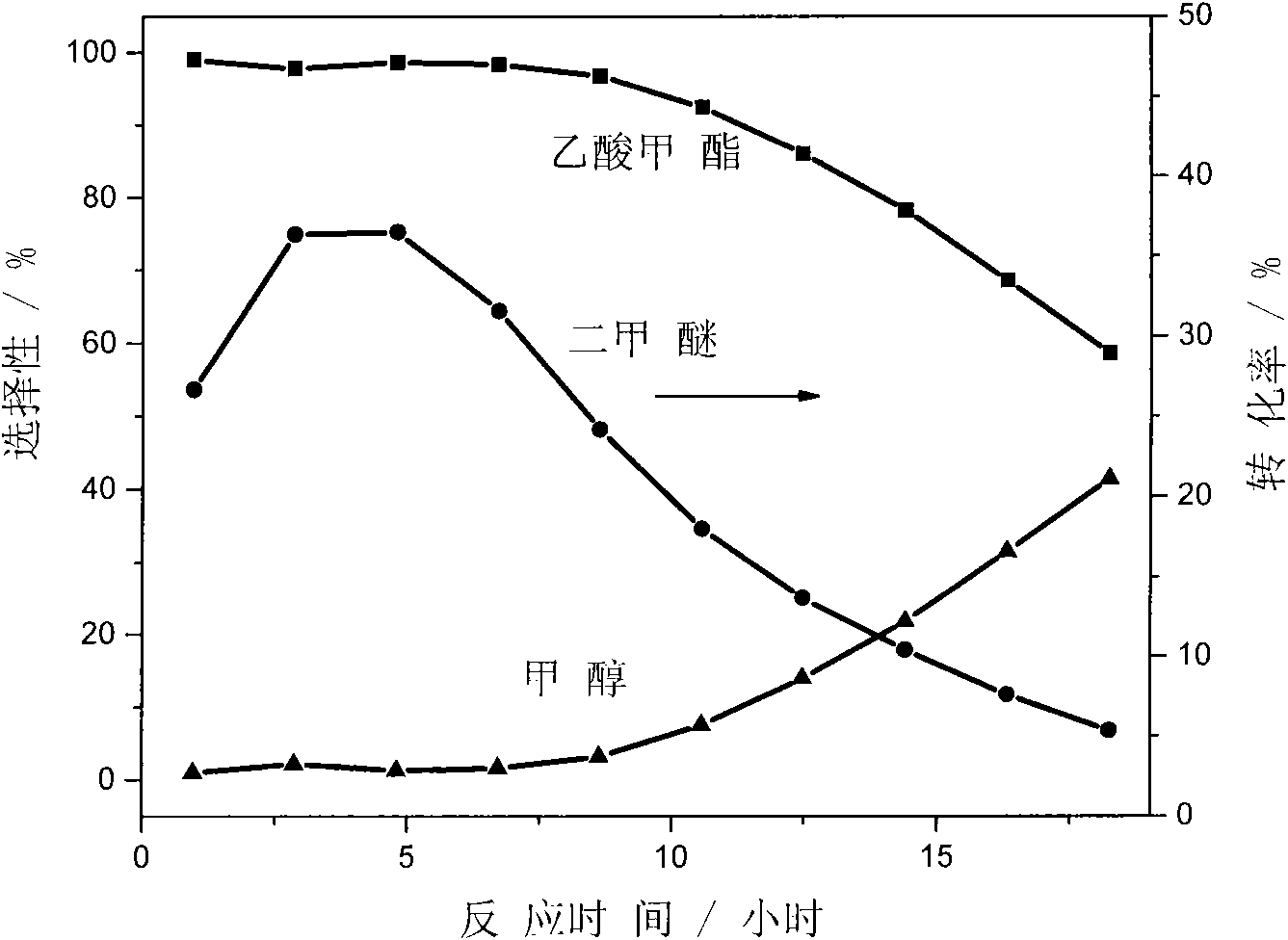

Embodiment 3-4

[0034] HNO used to treat #1 3 The concentration is 4mol / L and 8mol / L successively, and all the other preparation conditions are the same with embodiment example 2. And recorded as #3 and #4 catalysts in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com