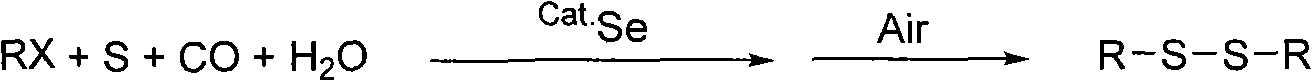

Method for synthesizing disulfide compound

A synthesis method and a disulfide technology are applied in the field of disulfide synthesis, which can solve the problems of complicated operation, unreusable catalyst and high production cost, and achieve simple and safe operation, favorable for large-scale industrial production and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 12.7g (0.1mol) of benzyl chloride, 1.6g (0.05mol) of sulfur powder, 0.32g (0.004mol) of selenium powder, 18mL (1mol) of water, and Sodium 4g (0.05mol) and solvent DMF 400mL, continue to pass through carbon monoxide, then heat to 95 ° C and stir for 2 hours, after cooling to room temperature, switch carbon monoxide gas to air, stir for 0.5 to 1 hour, at this time the unreacted selenium is separated out, filtered, and the filtrate is collected, and water with an amount 3 times the volume of the filtrate is added to the filtrate, at this time, the product dissolved in the filtrate is separated out, filtered, washed with water, and dried in vacuum to obtain the target product. The product has a purity of 100% and a yield of 94% as measured by proton nuclear magnetic resonance spectroscopy. (calculated as dibenzyl disulfide).

Embodiment 2

[0024] Only change the raw material of halogenated hydrocarbon, test method and other conditions are with embodiment 1.

[0025] Halogenated hydrocarbon

Embodiment 3

[0027] Temperature of reaction, sulfur powder amount, the reaction times are as follows, and experimental method and other conditions are with embodiment 1, and yield is as follows:

[0028] sulfur

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com