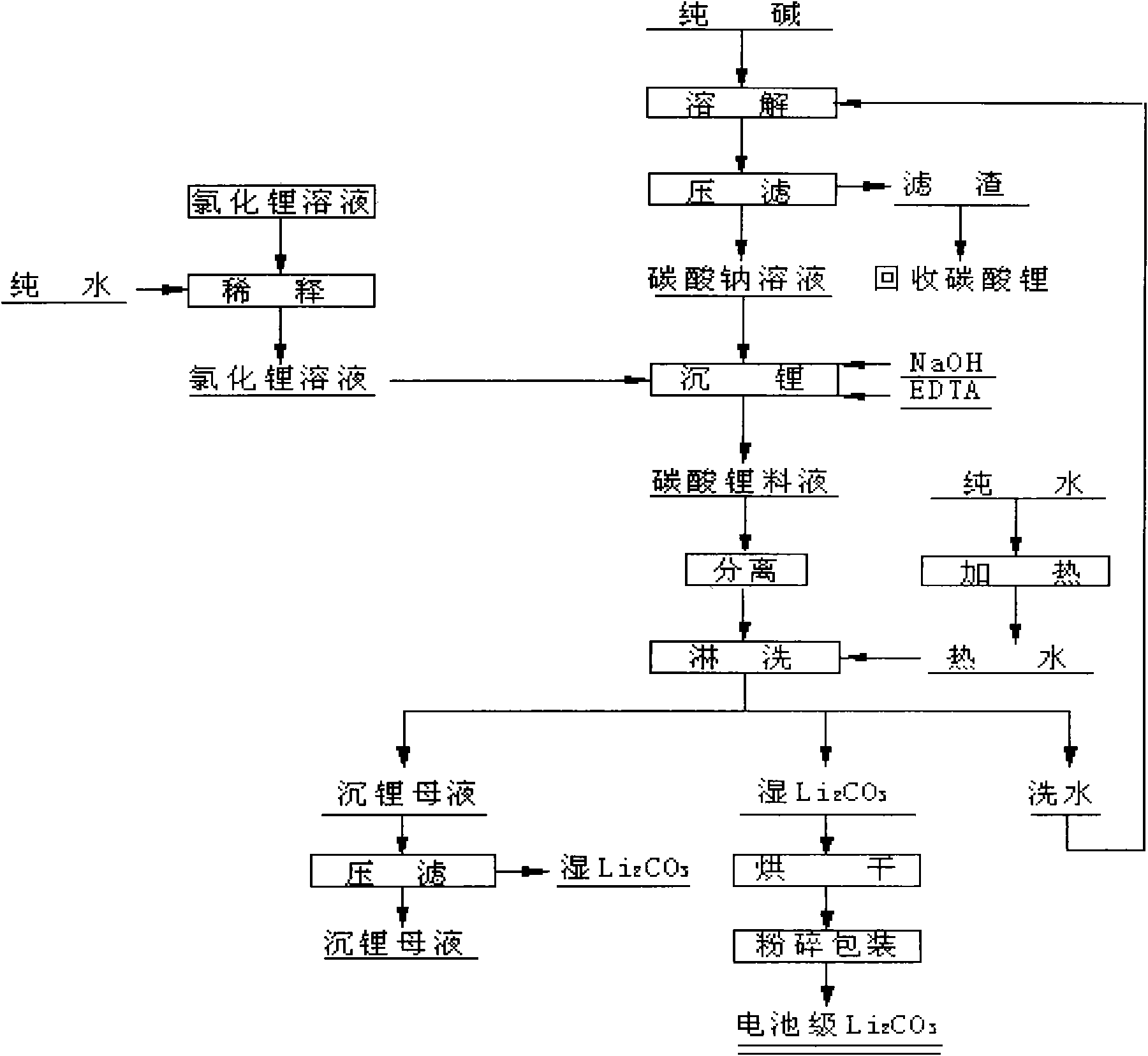

Method for preparing battery level lithium carbonate by using lithium chloride solution

A lithium chloride, lithium carbonate technology, applied in lithium carbonate;/acid carbonate, battery electrodes, circuits, etc., can solve problems such as high cost and complex technology, and achieve low production cost, simple process, The effect of good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Lithium chloride solution of 5 cubic meters, the calcium content in the lithium chloride solution of sampling analysis is 0.025g / l, will obtain lithium chloride solution and add pure water 7m 3 , the content of lithium chloride in the sampling analysis solution is 100g / l, be warmed up to 95 ℃, and add 2.33kg EDTA and 17kg mass concentration and be 30% liquid caustic soda, after stirring for 20 minutes, slowly add the carbonic acid of 220g / l wherein Sodium solution 7m 3 , the dropping time is 1.5 hours, keep the temperature for 1 hour after the addition, centrifuge, add pure water to rinse each time with a mass ratio of pure water to lithium carbonate of 1:2.5, rinse three times, and then dry at 140°C for 30 minutes , jet crushing to D 50 Obtain qualified battery grade lithium carbonate 685kg for 4.2 μm, the direct recovery rate of lithium is 65.4%. EDTA is ethylenediaminetetraacetic acid (Ethylene DiamineTetraacetic Acid), which is a complexing agent.

[0032] Such a...

Embodiment 2

[0038] at 2.5m 3 Add 2.5kg of activated carbon to the brine, absorb the organic matter in the brine at 80°C for 1 hour, and then press filter, raise the temperature of the press-filtered brine to 100°C, add liquid caustic soda to it, heat up and stir, adjust the pH to about 13, separate by plate pressure, and use 2.5m 3 Wash the magnesium hydroxide with water countercurrently for two times. After washing, mix the lotion and the mother liquor and pass carbon dioxide into it. The pH at the end point is controlled at 7, and 12 kg of activated carbon is added to it. The temperature is raised to 75°C, kept at a constant temperature for 1 hour, and press-filtered After the solution is sampled and analyzed, the calcium content in the lithium chloride solution is 0.03g / l, and the obtained lithium chloride solution is added to pure water for 7m 3 , the lithium chloride content in the sampling analysis solution is 100g / l, is heated up to 95 ℃, and adds 2.8kgEDTA and 17kg mass concentra...

Embodiment 3

[0040] at 2.5m 3Add 2.5kg of activated carbon to the brine, absorb the organic matter in the brine at 75°C for 1 hour, and then press filter, raise the temperature of the filtered brine to 100°C, add liquid caustic soda to it, heat up and stir, adjust the pH to about 13, separate by plate pressure, and use 3m 3 Wash the magnesium hydroxide with water countercurrently for two times. After washing, mix the lotion and the mother liquor and pass carbon dioxide into it. The final pH is controlled at 7, and 12kg of activated carbon is added to it. The temperature is raised to 75°C, kept at a constant temperature for 1 hour, and press-filtered After the solution is sampled and analyzed, the calcium content in the lithium chloride solution is 0.04g / l, and the obtained lithium chloride solution is added to pure water for 15m 3 , the lithium chloride content in the sampling analysis solution is 60g / l, is warmed up to 97 ℃, and adds 2.5kgEDTA and 24kg mass concentration and is 30% liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com