Organic ultracapacitor and manufacturing method thereof

A supercapacitor, capacitor technology, applied in the direction of capacitors, electrolytic capacitors, capacitor electrodes, etc., can solve the problems of increasing the thermal effect of capacitors, capacitor rupture, reducing capacitor life, etc., to achieve broad structural and modular design, high production level, guaranteed safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

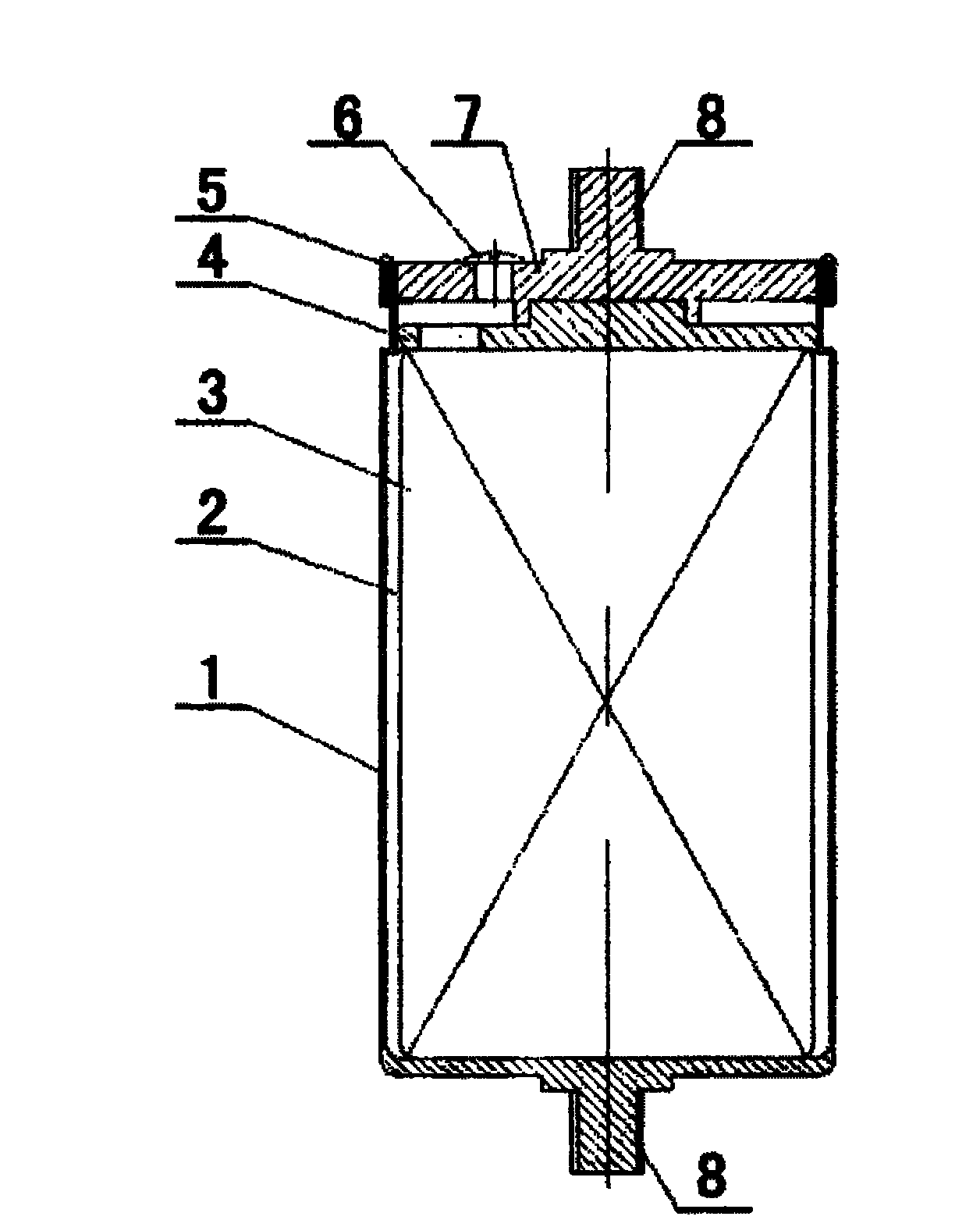

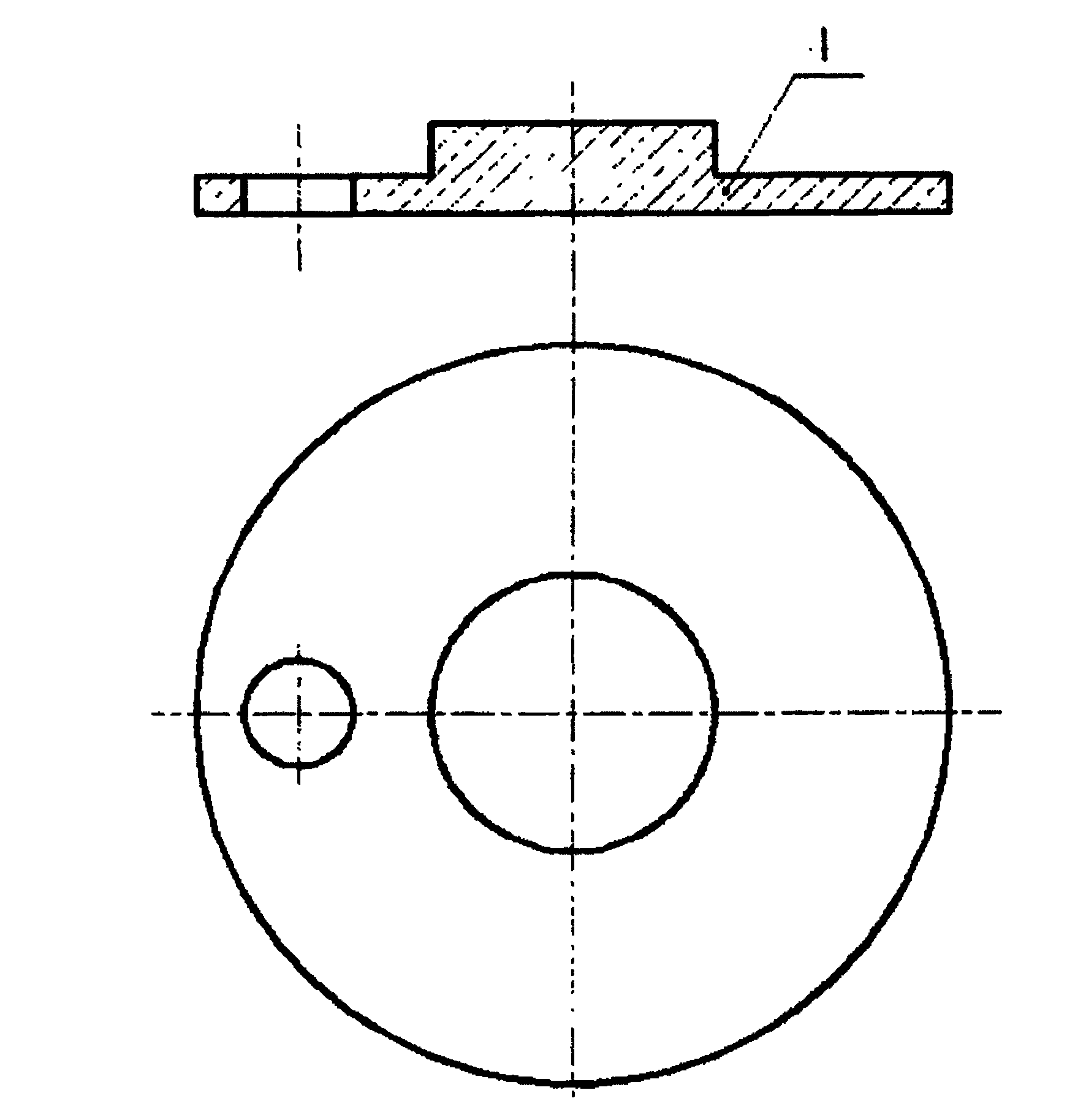

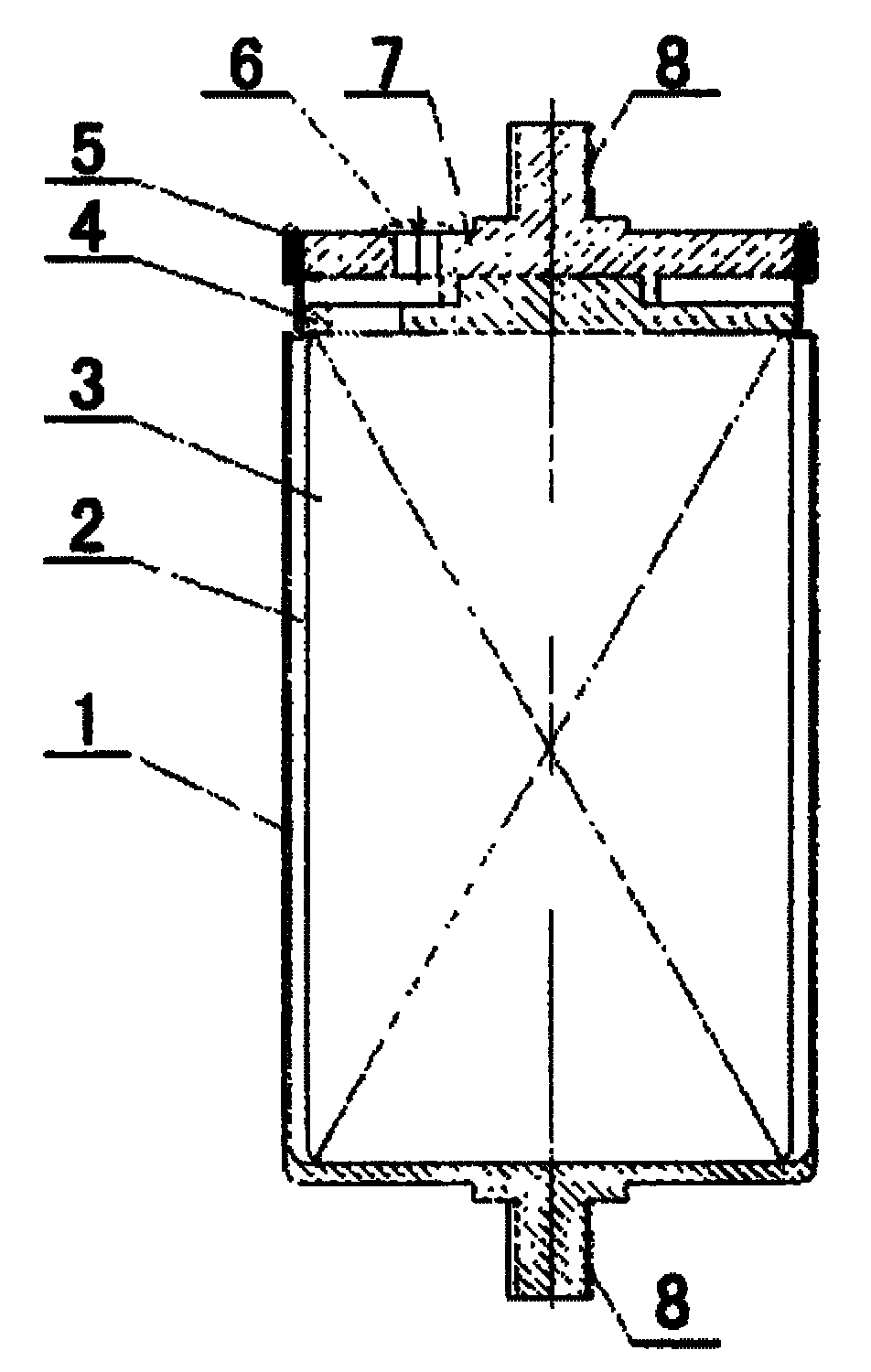

Embodiment 1

[0051]An organic supercapacitor, the inner diameter of the shell 1 is 76mm and the height is 140mm, the connecting piece 4 is a roughly circular sheet with a diameter of 74mm, and there is a raised connecting part in the middle, and the raised connecting part is a screw thread The connection structure corresponds to the screw connection structure provided in the middle of the upper cover 7 . The winding core group 3 is formed by winding two layers of aluminum foil coated with activated carbon material sandwiched by a cellulose membrane. The electrolytic solution 2 is an organic solution containing tetraethylammonium tetrafluoroborate. The welding area between the two ends of the core group 3 and the casing 1 and the connector 4 is 15% respectively, and the capacitor is assembled into a 3500F capacitor. After testing, the internal resistance of the capacitor is 0.25mΩ, and the maximum temperature of the positive and negative terminals is 32°C during the discharge process with ...

Embodiment 2

[0053] An organic supercapacitor, the shell 1 has an inner diameter of 90mm and a height of 160mm. The connecting piece 4 is roughly in the shape of a circular sheet with a diameter of 88mm. There is a raised connecting part in the middle, and the raised connecting part is a bayonet connection The structure corresponds to the bayonet connection structure provided in the middle of the upper cover 7 . The winding core group 3 is formed by winding two layers of aluminum foil coated with activated carbon material sandwiched by a cellulose membrane. The electrolytic solution 2 is an organic solution containing tetraethylammonium tetrafluoroborate. The welding areas of the two ends of the core group 3 and the casing 1 and the connector 4 are 70% respectively, and are assembled into a capacitor of 5000F. After testing, the internal resistance of the capacitor is 0.15mΩ, and the maximum temperature of the positive and negative terminals during the 500A current discharge process is 33...

Embodiment 3

[0055] An organic supercapacitor, the shell 1 has an inner diameter of 75mm and a height of 50mm, and the connecting piece 4 is roughly in the shape of a circular sheet with a diameter of 73mm. The core group 3 is formed by winding two layers of aluminum foil coated with activated carbon material sandwiched by a cellulose membrane. The electrolytic solution 2 is an organic solution containing tetraethylammonium tetrafluoroborate. The welding area between the two ends of the core group 3 and the casing 1 and the connector 4 is 5% respectively, and a capacitor of 650F is assembled. After testing, the internal resistance of the capacitor is 0.6mΩ, and the maximum temperature of the positive and negative terminals during the 150A current discharge process is 28°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com