Method for preparing high purity, high density and high yield Si3N4/SiO2 coaxial nano-cable array

A nano-cable, high-density technology, applied in the manufacture of coaxial cables, nano-structure manufacturing, cable/conductor manufacturing, etc. The effect of high product yield, controllable length, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention proposes a Si 3 N 4 / SiO 2 A method for preparing a coaxial nanocable array, characterized in that the method uses a pyrolysis organic precursor to synthesize Si on a catalyst-coated substrate. 3 N 4 / SiO 2 A coaxial nano-cable array, and includes the following steps and content:

[0029] (1) The polysilazane used has high silicon and nitrogen contents, exceeding 15at% and 20at% respectively, and the oxygen content is no more than 3at%, and the Si deposited by the method is 3 N 4 / SiO 2 The only silicon source for coaxial nanocable arrays.

[0030] (2) The polymer precursor is catalyzed or uncatalyzed thermal cross-linking and curing at 160-300°C for 0.5-2 hours under the atmosphere of high-purity nitrogen, argon or ammonia, and decomposes to remove water and most of the hydrogen to become semi- Transparent SiCN amorphous solid.

[0031] (3) The translucent amorphous solid is crushed in a high-wear-resistant agate container, then mixed wit...

Embodiment 1

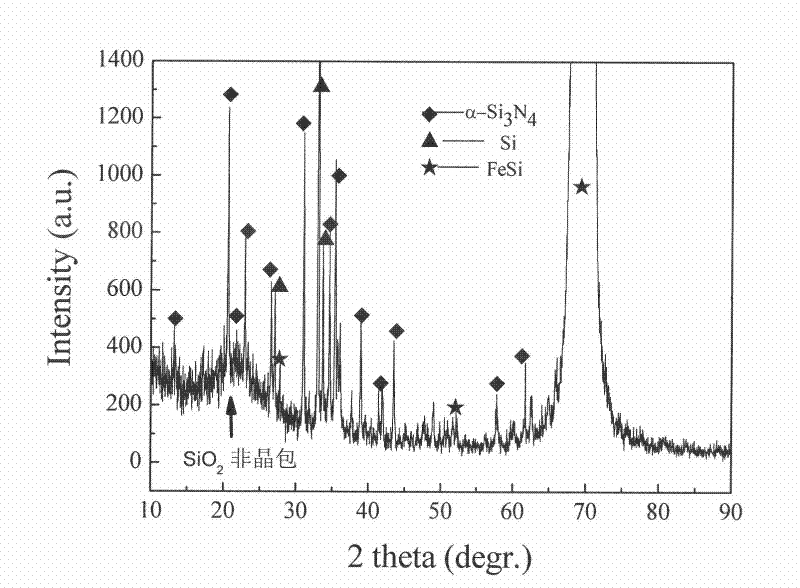

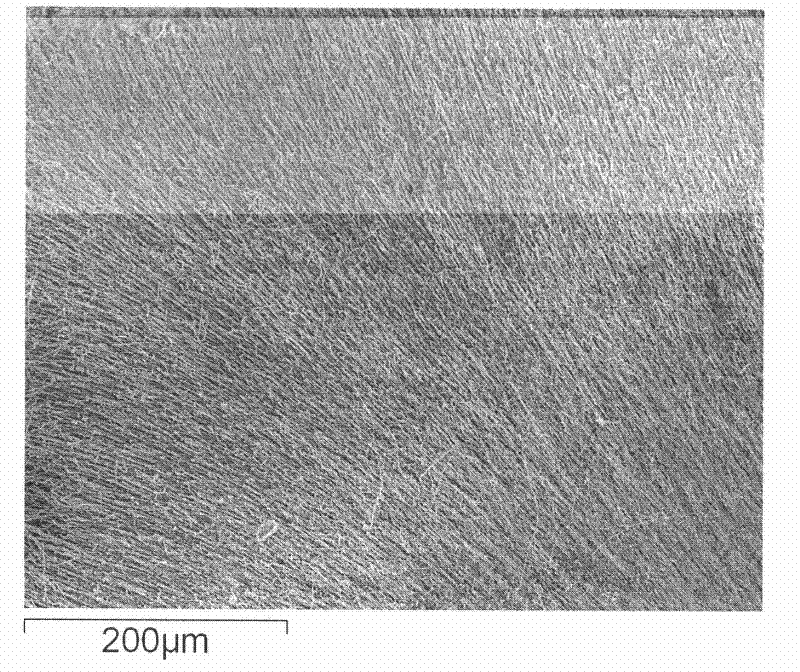

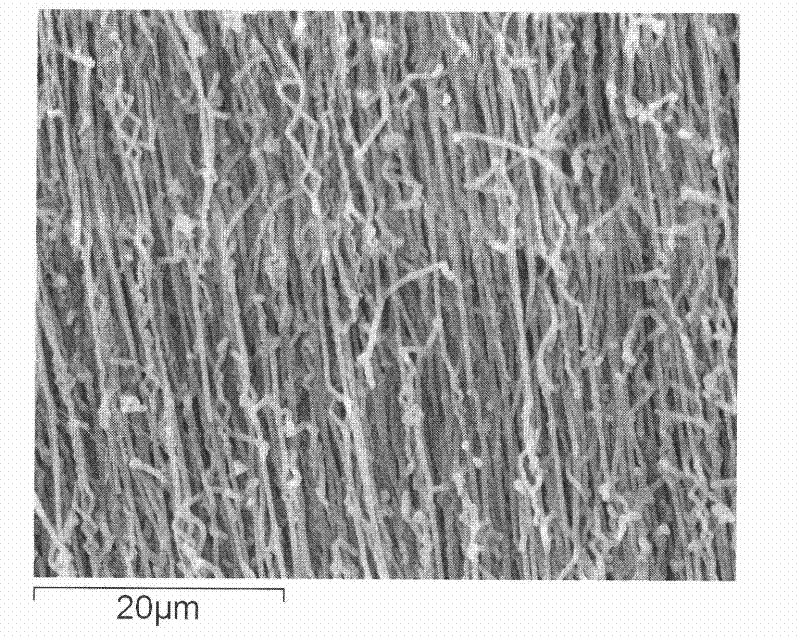

[0039] Example 1: The initial raw material is polysilazane perhydropolysilazane, which is a light yellow viscous liquid at room temperature. It is cured by thermal crosslinking without catalyst at 260°C for 0.5h, the protective atmosphere is nitrogen, and the air flow rate is 40ml / min to obtain translucent Amorphous SiCN solid. The SiCN solid was ground in an agate mortar, then mixed with high wear-resistant PZT balls with a diameter of 2 mm, and ground for 10 hours on a high-energy ball mill in a polyurethane ball mill jar. Take 0.3 g of solidified and pulverized precursor powder, and evenly distribute it on the bottom of the corundum crucible, then cut a small piece of silicon wafer coated with a 5 nm thick Fe film and place it on a ZrO2 layer about 2 mm high above the powder. 2 on the stand. Then put it in a tube furnace for high-temperature pyrolysis, keep it at 1250 °C for 2 hours, and then cool it naturally to room temperature to prepare Si 3 N 4 / SiO 2 Coaxial nanoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap