Petrol engine with turbo charging

A gasoline engine, turbocharged technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of difficult to meet higher requirements for exhaust emissions, difficult to increase engine speed again, large length, height and size, etc. Achieve the effect of improving fuel efficiency, reducing weight, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with accompanying drawing:

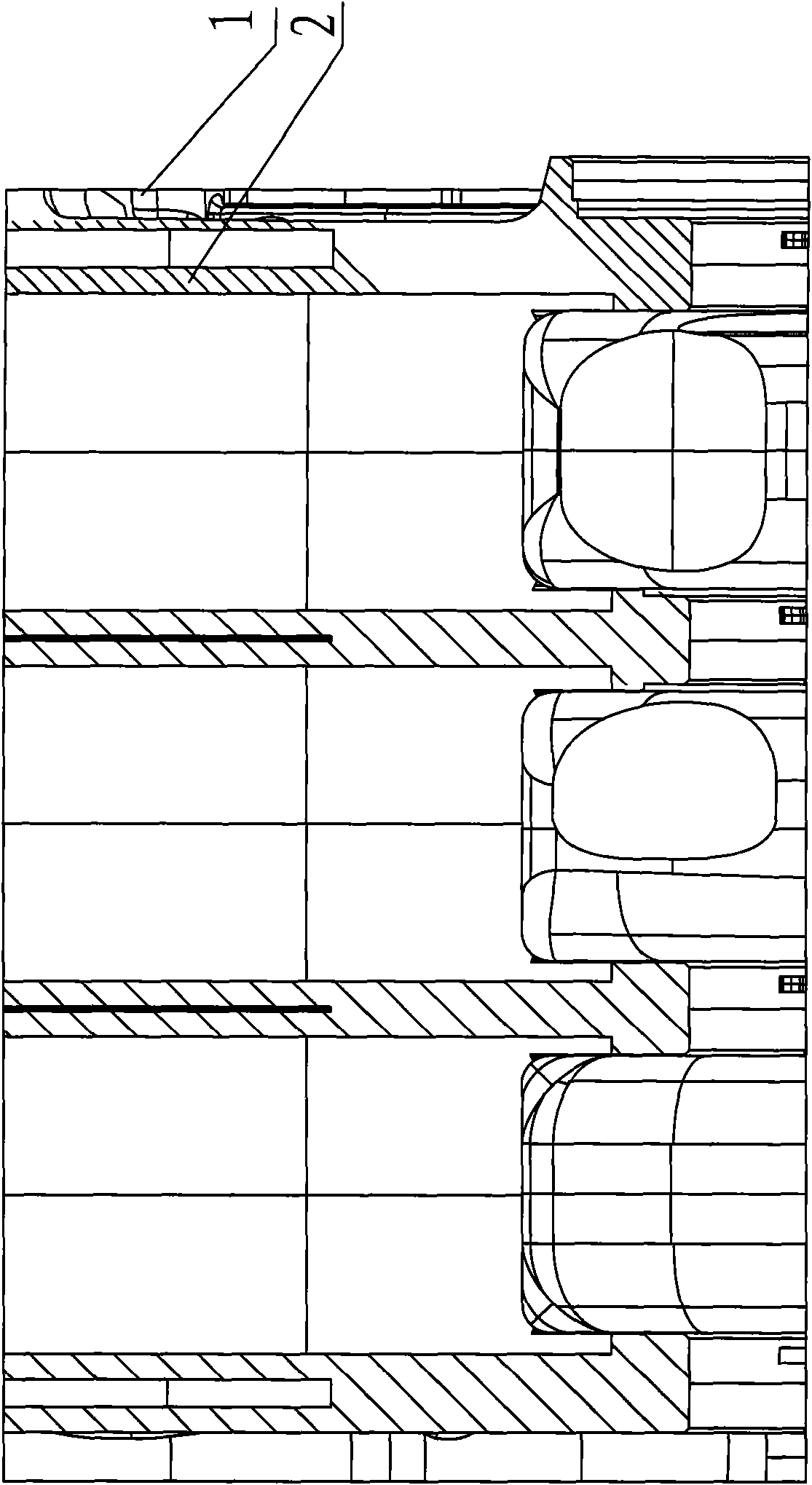

[0029] as attached figure 1 To attach image 3 As shown, a turbocharged gasoline engine includes a cylinder block 1, a cylinder liner 2, an intake valve 3, a spark plug hole 4, an exhaust valve 5, a combustion chamber 8, a crankshaft 9, a connecting rod 10, a piston 11, Intake manifold 14, exhaust manifold 15, turbocharger 18.

[0030] As we all know, the engine generates power by burning fuel in the cylinder. Since the amount of fuel input is limited by the amount of air sucked into the cylinder, the power generated by the engine will also be limited. In the best state, increasing the output power can only increase the amount of fuel by compressing more air into the cylinder, thereby improving the combustion performance. Therefore, under the current technical conditions, the turbocharger is the only mechanical device that can increase the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com