System for recycling exhaust manifold heat to realize engine boosting

An exhaust manifold and engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as low efficiency and achieve the effect of increasing power per liter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

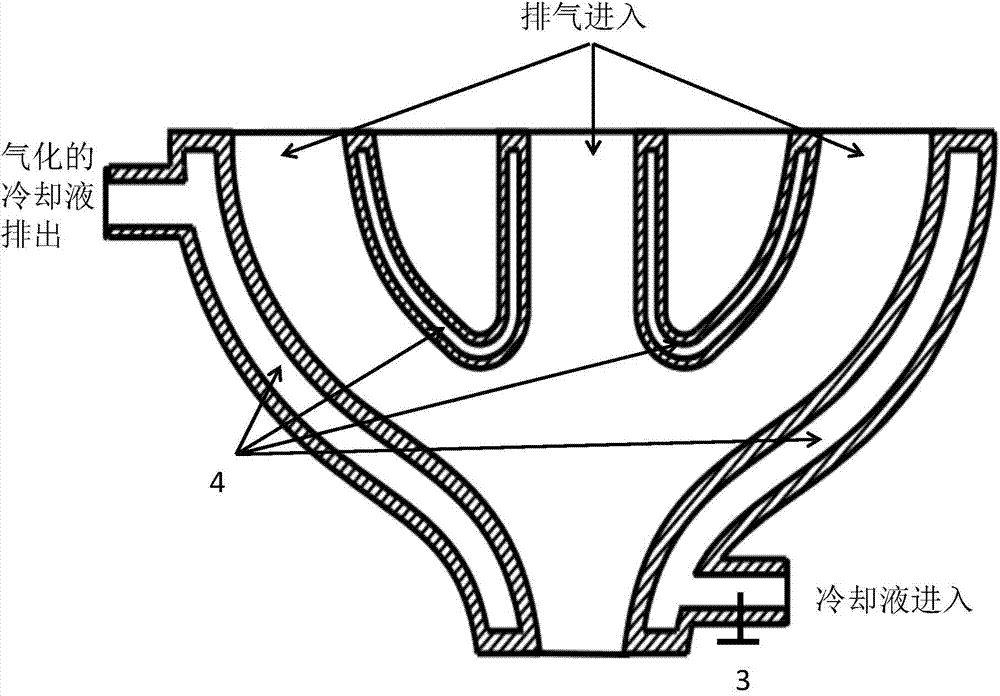

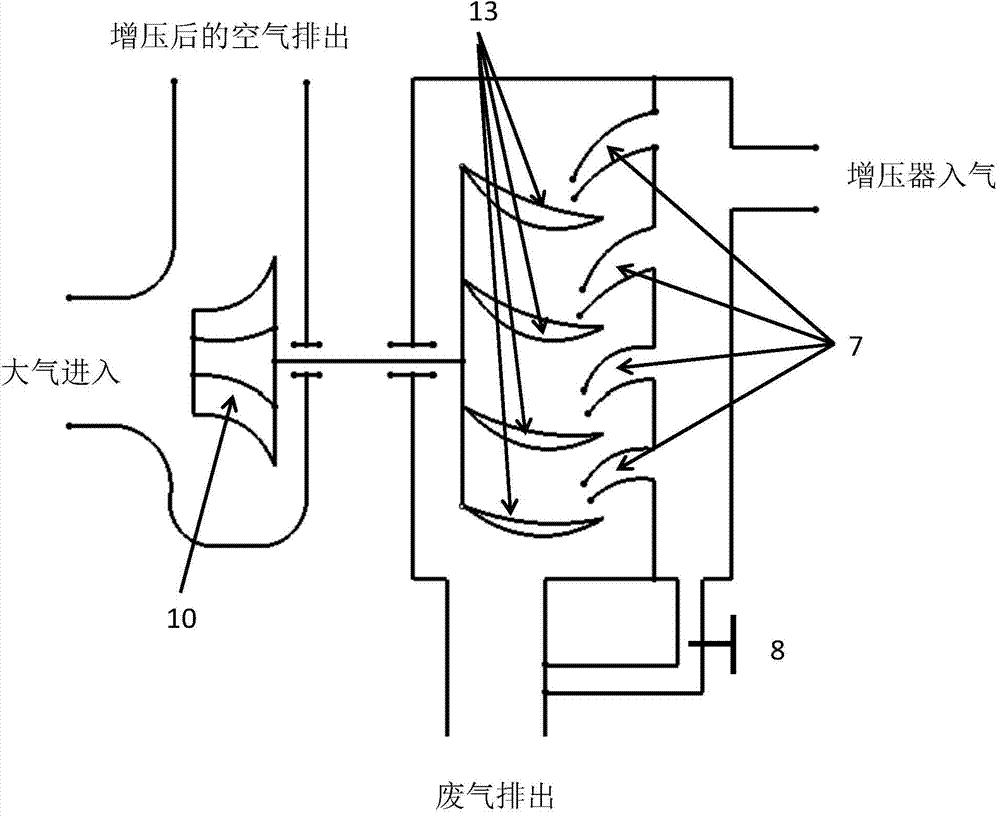

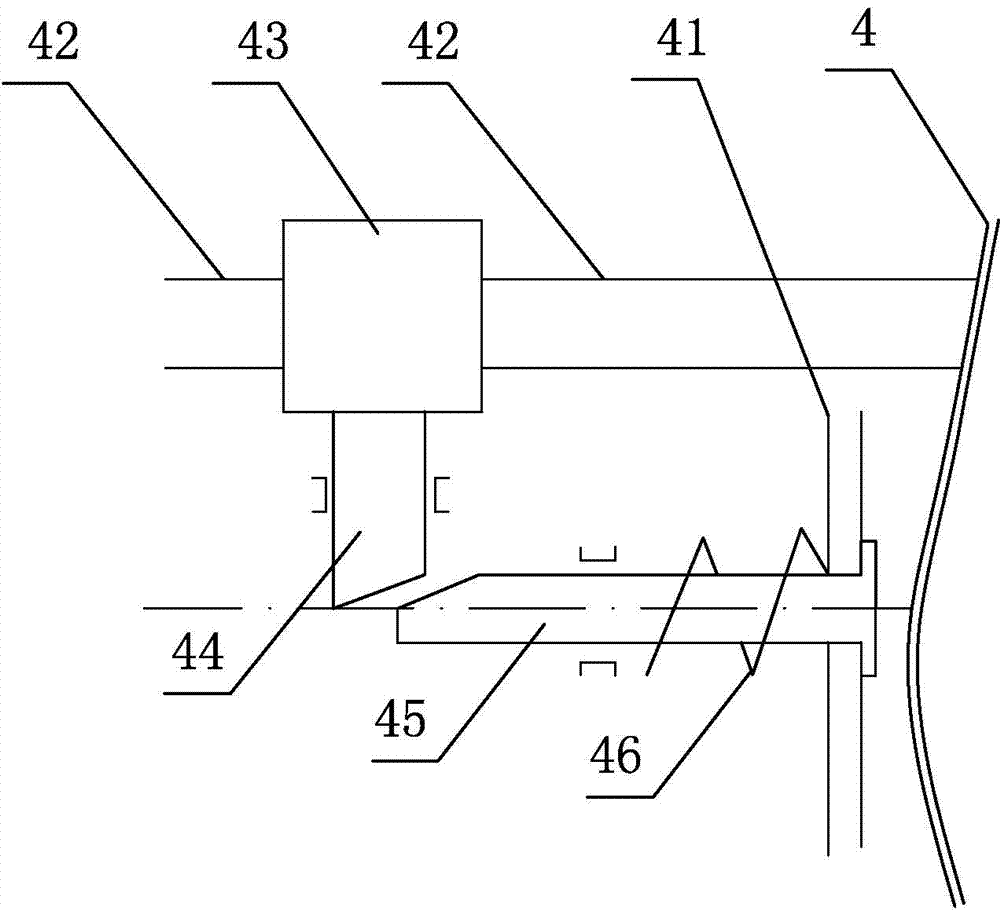

[0014] Embodiment: the present invention recovers exhaust manifold heat and realizes the system of engine supercharging, as attached figure 1 , attached figure 2 As shown, it includes an exhaust manifold, a supercharger driven by high-temperature steam; the supercharger includes a turbine and a compressor, and a transmission connection is set between the turbine blades 13 in the turbine and the compressor impeller 10 in the compressor; The exhaust manifold water jacket 4 is covered on the manifold; the exhaust manifold water jacket 4 is a hollow body through the interior, and one end is connected to the coolant from the radiator or the engine water outlet through the inlet, and the coolant is in the exhaust The inside of the manifold water jacket 4 is heated to a high-temperature gas state, and the gasified high-temperature gas is output to the air inlet of the turbine through the outlet; the turbine has a separate air intake chamber and a turbine chamber, and a nozzle 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com