Fuel system carbon deposit undisassembly abluent of diesel engine

A cleaning agent, diesel engine technology, used in fuel, petroleum industry, machinery and equipment, etc., can solve the problems of ineffective removal of carbon deposits, increase of carbon deposits in combustion chambers, corrosion of metal parts, etc., to inhibit the formation of fuel system carbon deposits, The effect of improving the mixture ratio of oil and gas, reducing fuel consumption and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Ashless cleaning agent

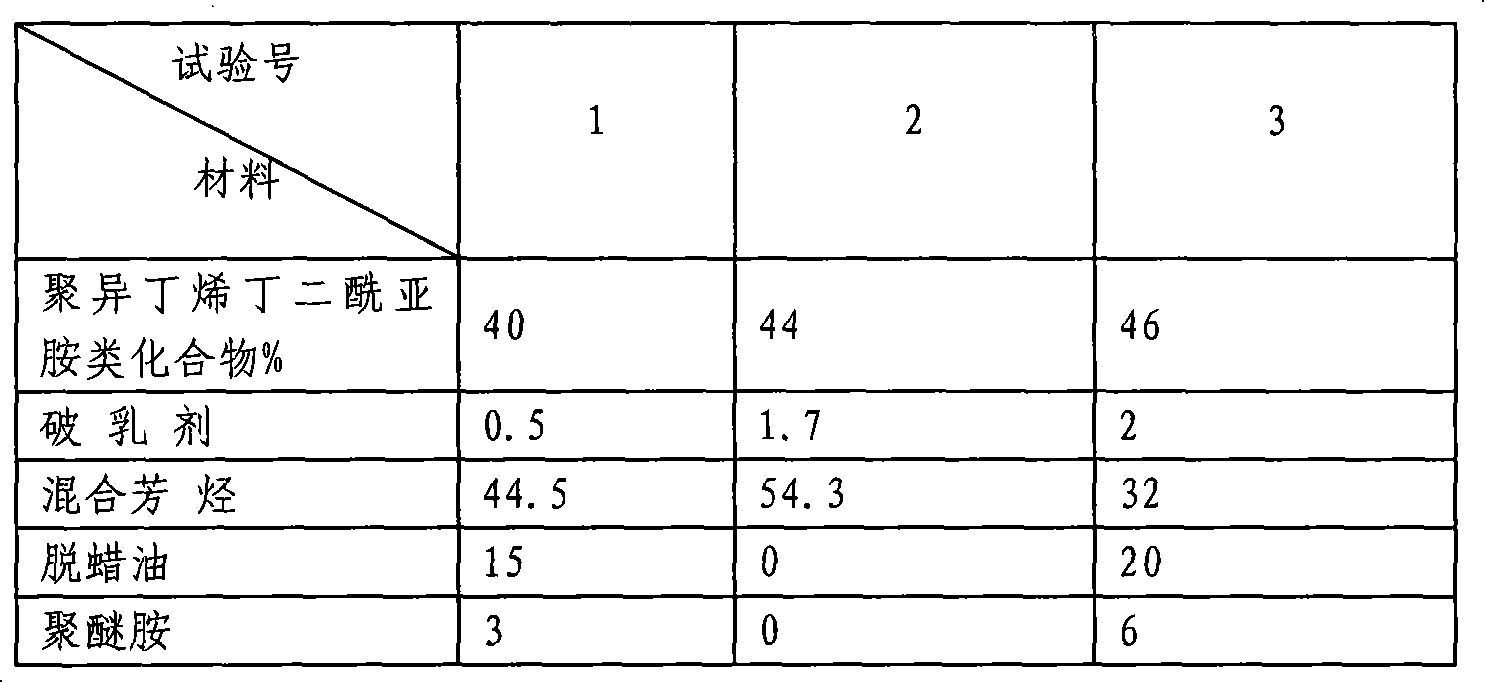

[0020] According to the components in Table 1, blend and prepare a fuel-based cleaning agent

[0021] Table 1 Composition of ash-free cleaning agent

[0022]

[0023] Use L-3 vehicle diesel detergency evaluation device to detect the amount of carbon deposition of the three samples. The samples are shown in Table 2

[0024] Table 2 Cleaning effect of ash-free cleaning agent

[0025] Test No.

Embodiment 2

[0027] ash cleaning agent

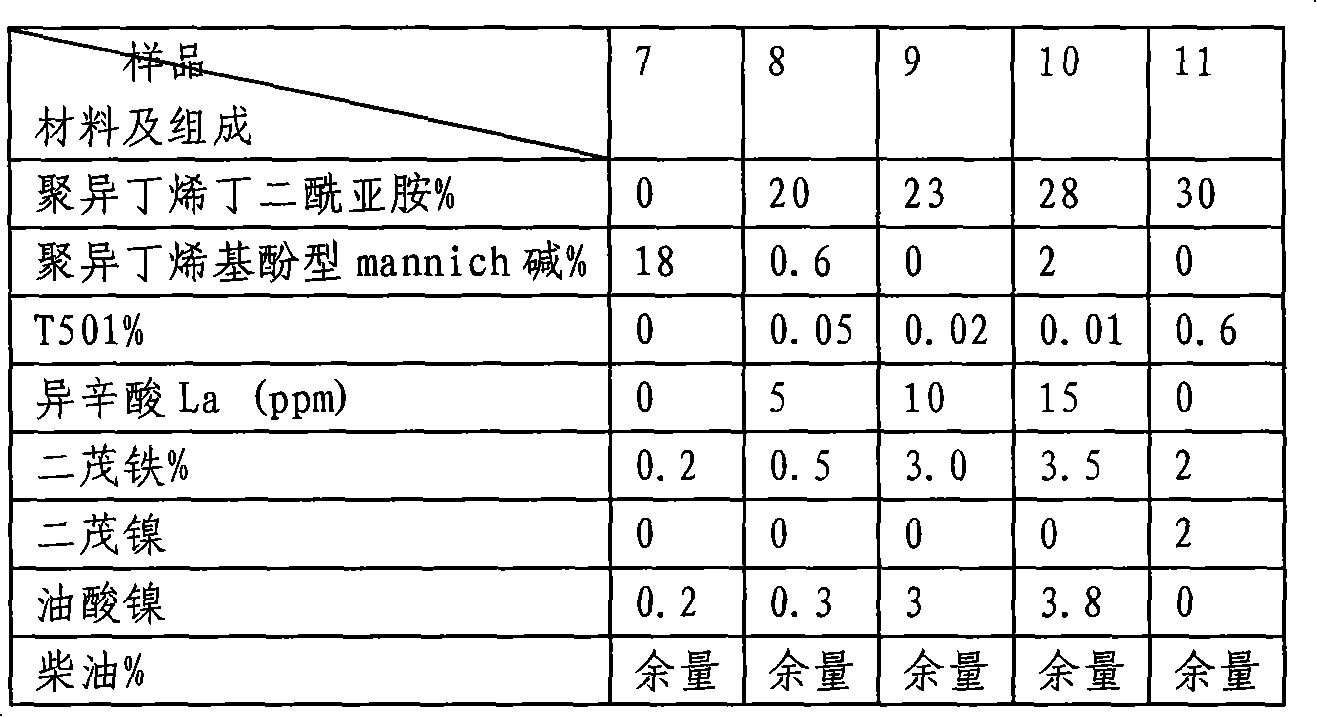

[0028] According to Table 3, the components are blended and formulated into a fuel-based cleaning agent, and the L-3 vehicle diesel detergency evaluation device is used to detect the carbon deposit generation of the 3 samples. The samples are shown in Table 3.

[0029] Table 3 Partly has the cleaning effect of gray cleaning agent

[0030] Test No.

Embodiment 3

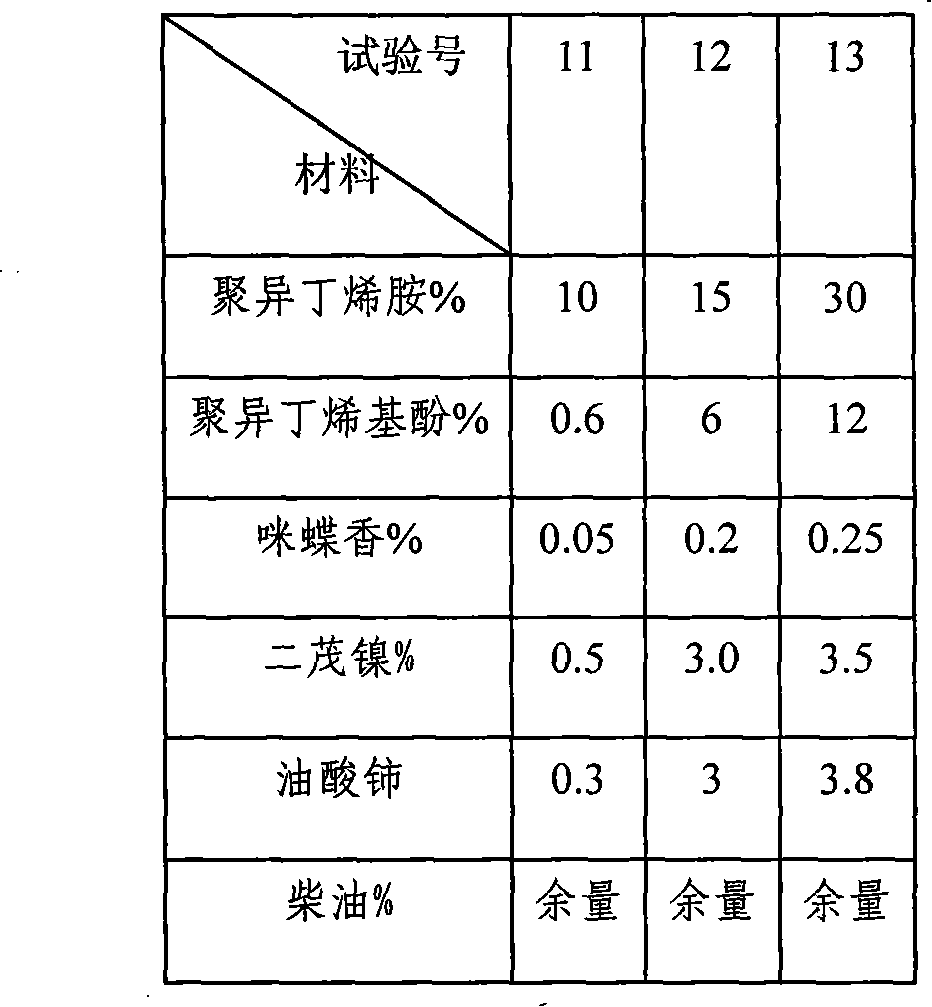

[0032] According to the components in Table 4, blend and prepare a fuel-based cleaning agent

[0033] The components in Table 4 are blended and formulated into a fuel-based cleaning agent

[0034]

[0035] According to the components in Table 4, the amount of carbon deposition of the samples tested by the L-3 vehicle diesel detergency evaluation device for the fuel-based cleaning agent is shown in Table 5.

[0036] Table 5 Partially has the cleaning effect of gray cleaning agent

[0037] Test No.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com