Method for manufacturing fuel through straw quick thermal cracking and fuel product thereof

A thermal cracking and fuel technology, applied in the field of straw thermal cracking, can solve problems such as immaturity, and achieve the effects of low production cost, good control of rapid thermal cracking conditions, and strong safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

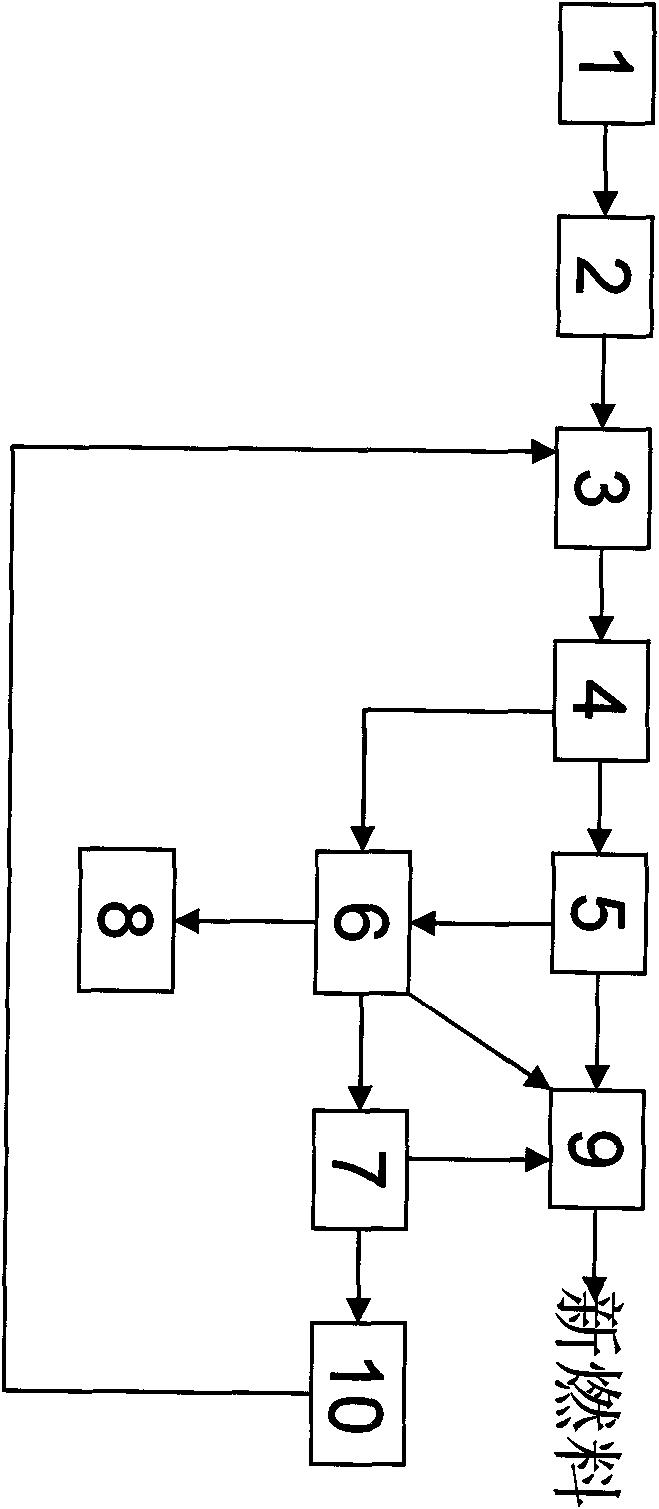

[0026] Example 1. A method for fast pyrolysis of straw to produce fuel, such as figure 1 shown. It includes the following steps:

[0027] 1. Crushing of straw materials; 2. Drying of crushed materials; 3. Thermal cracking of dry materials; 4. Sending thermal cracking products to cyclone dust collectors to separate gas and solids; 5. Solids obtained by cyclone dust removal Biomass charcoal is condensed and sent to mixing and grinding step 9; 6. The gas obtained by cyclone dust removal is rectified and washed, and the gaseous biomass oil obtained by rectification and washing is sent to step 7 for condensation, and the tower bottom heavy biomass obtained by rectification and washing is Substance oil and solid biomass charcoal are sent to mixing and grinding step 9, and the low boiling point biomass oil obtained by rectification and washing is sent to collection step 8; 7. Condensation of gaseous biomass oil; 8. Collection of low boiling point biomass oil; 9. Mix and grind the ...

Embodiment 2

[0030] Example 2. The utility model relates to a fuel product produced according to the method for producing fuel by rapid pyrolysis of straw. The proportion of the fuel product is 30% of biochar, 15% of heavy biomass oil, 0.2% of surfactant, and the rest is water. The particle size of biochar after grinding is ≤10μm.

Embodiment 3

[0031] Example 3. The utility model relates to a fuel product produced according to the method for producing fuel by rapid pyrolysis of straw. The proportion of the fuel product is 60% of biochar, 2% of heavy biomass oil, 1% of surfactant, and the rest is water. The particle size of biochar after grinding is ≤10μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com