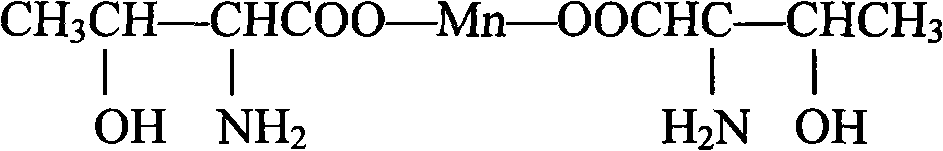

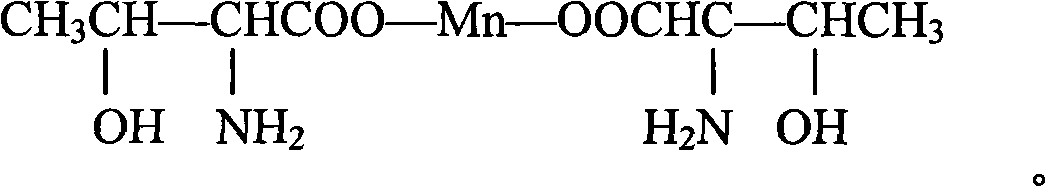

Threonine manganese as well as preparation method and application thereof

A technology of manganese threonine and threonine, which is applied in the field of amino acid chelate and its preparation, can solve the problems of solid threonine solubility, low biological potency, complicated operation process, etc., and improve the fertilization rate and hatching rate, high biological titer, and the effect of reducing the rate of soft-shell eggs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

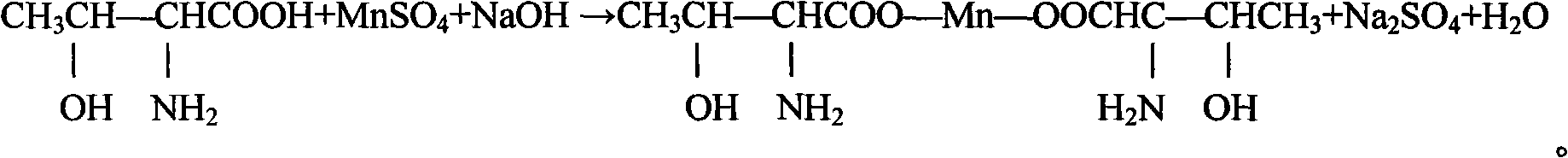

Method used

Image

Examples

Embodiment 1

[0026] A manganese threonine finished product of the present invention is prepared through the following steps: firstly open the nitrogen valve, replace the air in the reactor, then under the protection of nitrogen, take 41.75g of threonine and put it into a tank containing 100g of reaction water. Fully stir in the reaction kettle, then drop 29.62g of manganese sulfate monohydrate, adjust the pH value of the reaction mixture to 5.8 with 13.88g of sodium hydroxide at a temperature of 93°C, react for 1.5h under normal pressure, and then use the reaction product Extract with ethanol for 15 minutes, and the volume ratio of ethanol to reaction product is 8:1. The precipitate after extraction is dried at 100° C. in a flash, and crushed to prepare the finished product of manganese threonine.

[0027] Gel filtration chromatography (GB / T 13080.2-2005) is used to detect the chelation rate in the finished product of the reaction product, and the values are all above 80%.

[0028] The...

Embodiment 2

[0039] A manganese threonine finished product of the present invention is prepared through the following steps: first open the nitrogen valve, replace the air in the reactor, and under the protection of nitrogen, take 348Kg threonine and put it into the reaction tank containing 1000kg of reaction water. Fully stir in the kettle, then put 247Kg of manganese sulfate monohydrate, maintain the pH value of the reaction mixture at 93°C with 115Kg of sodium hydroxide, react for 2 hours under normal pressure, and then send the reaction product to the concentration tank , at 0.5kgf / cm 2 Vacuum concentration at a temperature of 90°C for 45 minutes. After the product is viscous, the concentrate is fed into a tray, flashed and dried at 120°C, and crushed to prepare the finished product of manganese threonine.

[0040] Gel filtration chromatography (GB / T 13080.2-2005) is used to detect the chelation rate in the finished product of the reaction product, and the values are all above 80%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com