NaAlH* compound hydrogen storage material catalyzed by Ce hydride and preparation method thereof

A technology for hydrogen storage material and hydride, which is applied in the field of NaAlH4 composite hydrogen storage material catalyzed by Ce hydride and its preparation, can solve the problems of consumption of complex hydride, damage to fuel cell performance, reduction of hydrogen storage capacity, etc. Effect of cycle stability and reversible hydrogen storage and desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

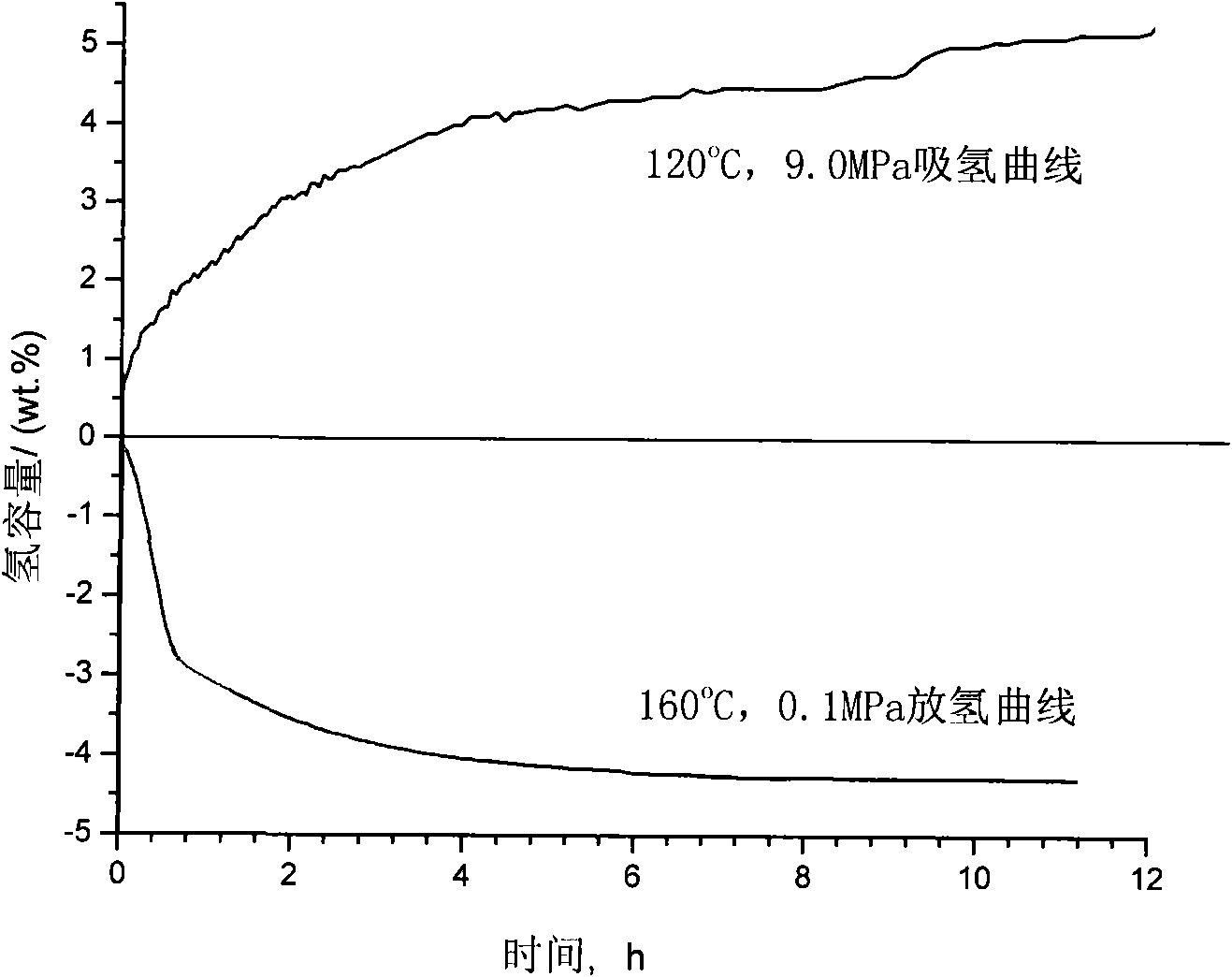

[0026] Using NaAlH produced by Acros organics company in the United States 4 It is raw material (purity is 93%, particle size is -325 mesh). In a glove box with an oxygen and water content of less than 1ppm, 4% mol of the CeH prepared by the above method 2.5 with 96% molar NaAlH 4 After mechanically grinding and mixing evenly, seal stainless steel balls (diameter 8mm) together with them into the ball mill jar with a weight ratio of 8:1 to 15:1, and mechanical pump at room temperature (ultimate vacuum 10 -2 Pa) After vacuuming for 20-30 minutes, fill it with hydrogen gas of 1.8-3Mpa, then ball mill for 5-10 hours at a vibration frequency of 3000 times / min, in a ball mill with an amplitude of 0-44mm and amplitude ≠0, and obtain 4% mole CeH 2.5 Catalyzed NaAlH 4 Hydrogen storage material, its hydrogen absorption and desorption kinetic curve is as follows figure 1 Shown, the hydrogen storage and discharge capacity is based on NaAlH 4 and doped CeH 2.5Total weight calculation...

Embodiment 2

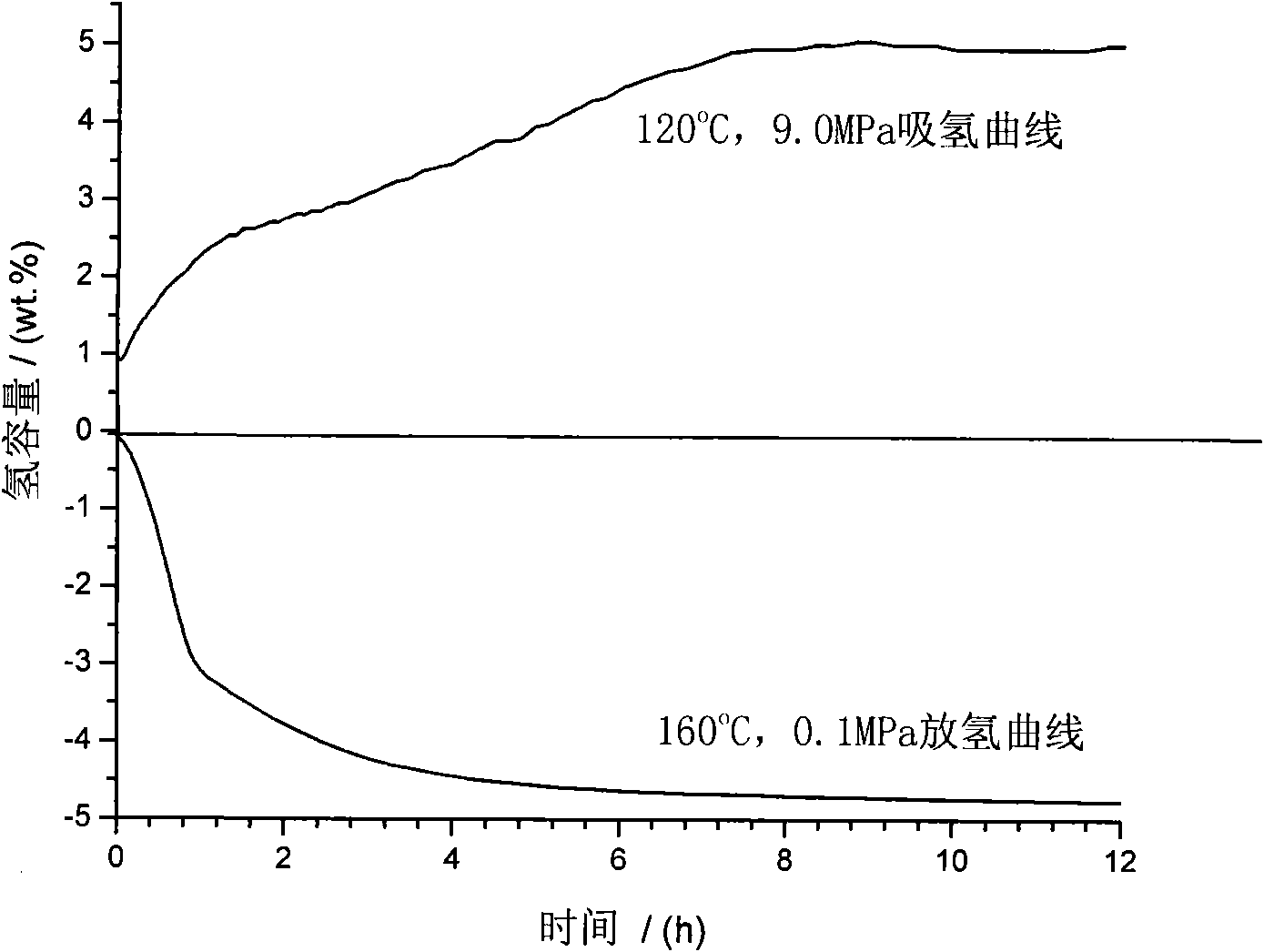

[0028] Using NaAlH produced by Acros organics company in the United States 4 It is raw material (purity is 93%, particle size is -325 mesh). In a glove box with an oxygen and water content of less than 1ppm, 1% mole of the CeH prepared by the above method 2.5 with 99% molar NaAlH 4 After mechanically grinding and mixing evenly, seal stainless steel balls (diameter 8mm) together with them into the ball mill jar with a weight ratio of ball to material of 8:1~15:1, vacuumize at room temperature for 20~30min, fill with 1.8~3Mpa hydrogen, and then Vibration frequency is 3000 times / min, ball milling in a ball mill with amplitude 0-44mm and amplitude ≠0 for 5-10h to obtain 1mol% CeH 2.5 Catalyzed NaAlH 4 Composite hydrogen storage material, its hydrogen absorption and desorption kinetic curve is as follows figure 2 Shown, the hydrogen storage and discharge capacity is based on NaAlH 4 and doped CeH 2.5 Calculated by the total weight, the material absorbs 4.0% of hydrogen withi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com