CeH2.5-NaH-Al composite hydrogen storage material and preparation method thereof

A hydrogen storage material, storage and storage technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, hydrogen, etc. problem, to achieve the effect of good cycle stability and reversible hydrogen storage and desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

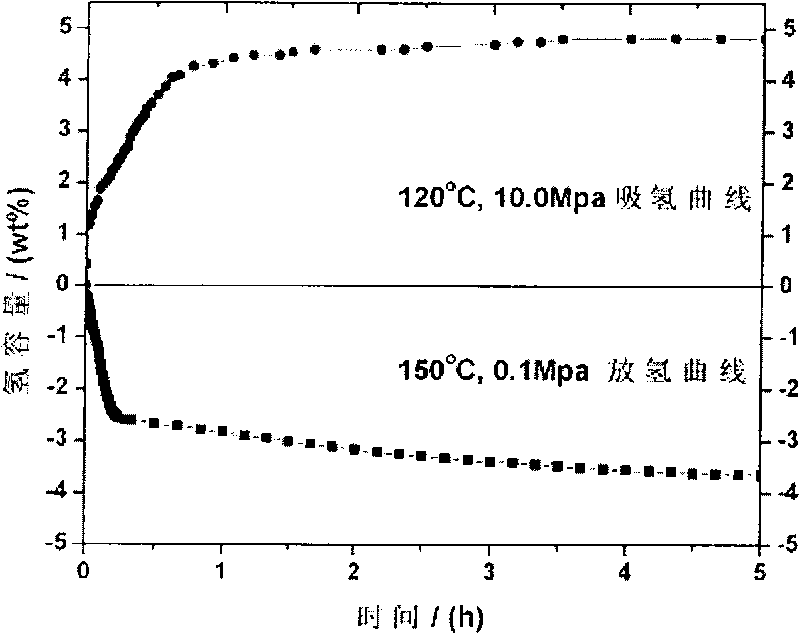

Embodiment 1

[0025] Using commercially available NaH powder (purity 95%, average particle size about 74 μm) and Al powder (purity ≥ 99%, particle size 74-154 μm) as raw materials, in a glove box with oxygen and water content less than 1ppm, molar Mixed at a ratio of 1:1, 4% mole of the CeH prepared by the above method 2.5 After mechanically grinding and mixing with the mixture of 48% mole NaH and 48% mole Al, stainless steel balls (diameter 12mm) are sealed into the ball mill jar with the weight ratio of ball material 35:1, and the room temperature mechanical pump (ultimate vacuum 10 -2Pa) Vacuum for 20 to 30 minutes and then fill with 5Mpa hydrogen, then ball mill for 12 hours at a vibration frequency of 3000 times / min in a ball mill with an amplitude of 0 to 44 mm and an amplitude ≠ 0 to obtain a 4% mole CeH 2.5 CeH 2.5 -NaH-Al composite hydrogen storage material, its hydrogen absorption and desorption kinetic curve is as follows figure 1 Shown, the hydrogen storage and discharge capac...

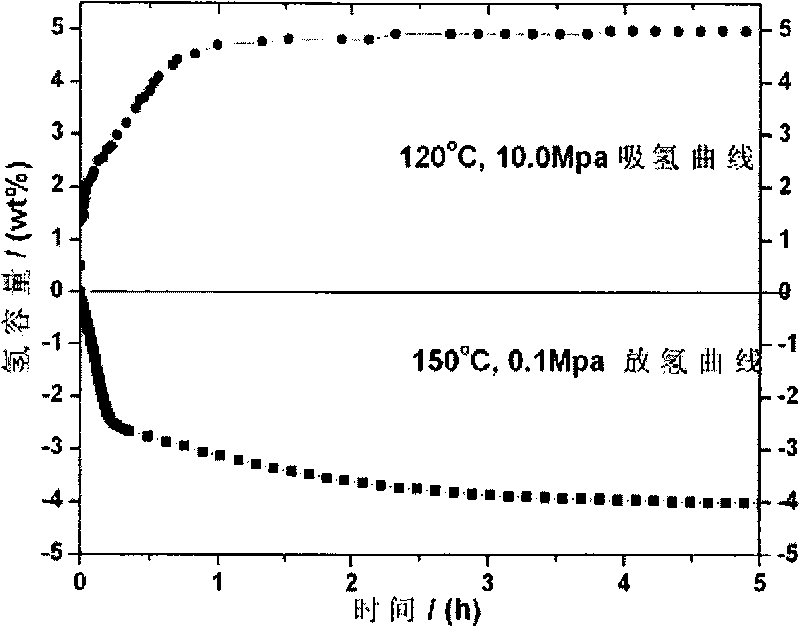

Embodiment 2

[0027] Using commercially available NaH powder (purity 95%, average particle size about 74 μm) and Al powder (purity ≥ 99%, particle size 74-154 μm) as raw materials, in a glove box with oxygen and water content less than 1ppm, molar Mixed at a ratio of 1:1, 3% mole of the CeH prepared by the above method 2.5 After mechanically grinding and mixing with the mixture of 48.5% mole NaH and 48.5% mole Al, stainless steel balls (diameter 12mm) are sealed into the ball mill jar with the weight ratio of ball material 35:1, and the room temperature mechanical pump (ultimate vacuum 10 -2 Pa) After evacuating for 20-30 minutes, fill it with 5Mpa hydrogen, then ball mill for 18 hours at a vibration frequency of 3000 times / min, in a ball mill with an amplitude of 0-44 mm and an amplitude ≠ 0, to obtain 3% mole CeH 2.5 Catalyzed NaH / Al material, its hydrogen absorption and desorption kinetic curve is as follows figure 2 Shown, the hydrogen storage and discharge capacity is based on NaH / Al...

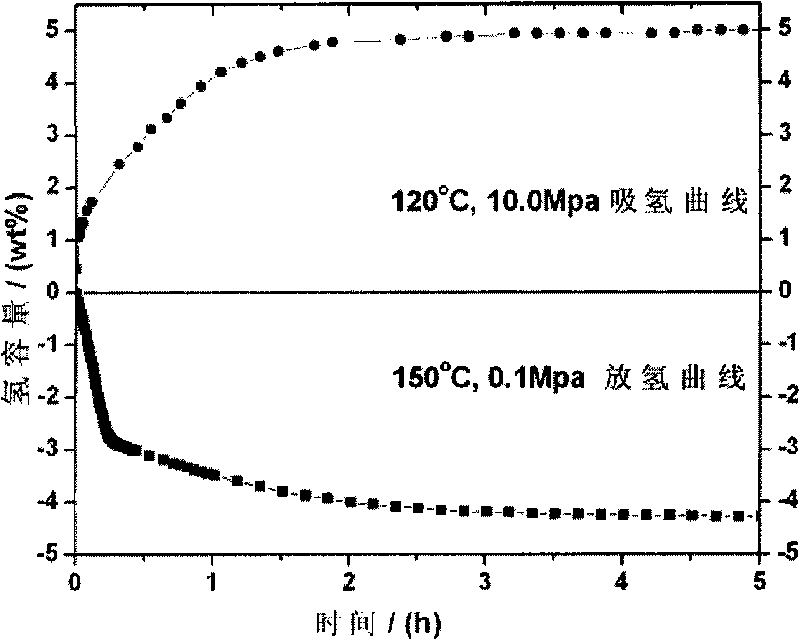

Embodiment 3

[0029] Using commercially available NaH powder (purity 95%, average particle size about 74 μm) and Al powder (purity ≥ 99%, particle size 74-154 μm) as raw materials, in a glove box with oxygen and water content less than 1ppm, molar Mixed at a ratio of 1:1, 3% mole of the CeH prepared by the above method 2.5 After mechanically grinding and mixing the mixture of 48.5% mole NaH and 48.5% mole Al, stainless steel balls (diameter 12mm) are sealed into the ball mill jar with the weight ratio of ball material 44:1, and the room temperature mechanical pump (ultimate vacuum 10 -2 Pa) Vacuumize for 20-30 minutes and fill with 6Mpa hydrogen, then ball mill for 18 hours at a vibration frequency of 3000 times / min in a ball mill with an amplitude of 0-44mm and amplitude ≠0 to obtain 3% mole CeH 2.5 -NaH-Al composite hydrogen storage material, its hydrogen absorption and desorption kinetic curve is as follows image 3 Shown, the hydrogen storage and discharge capacity is based on NaH / Al a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com