Fireproof plate

A technology of fireproof board and fireproof glue, which is applied in the direction of adhesive type, lamination, layered products, etc., can solve the problems of high cost, insufficient stability, troublesome installation of compartment materials, etc., and achieve weight reduction, convenient installation, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

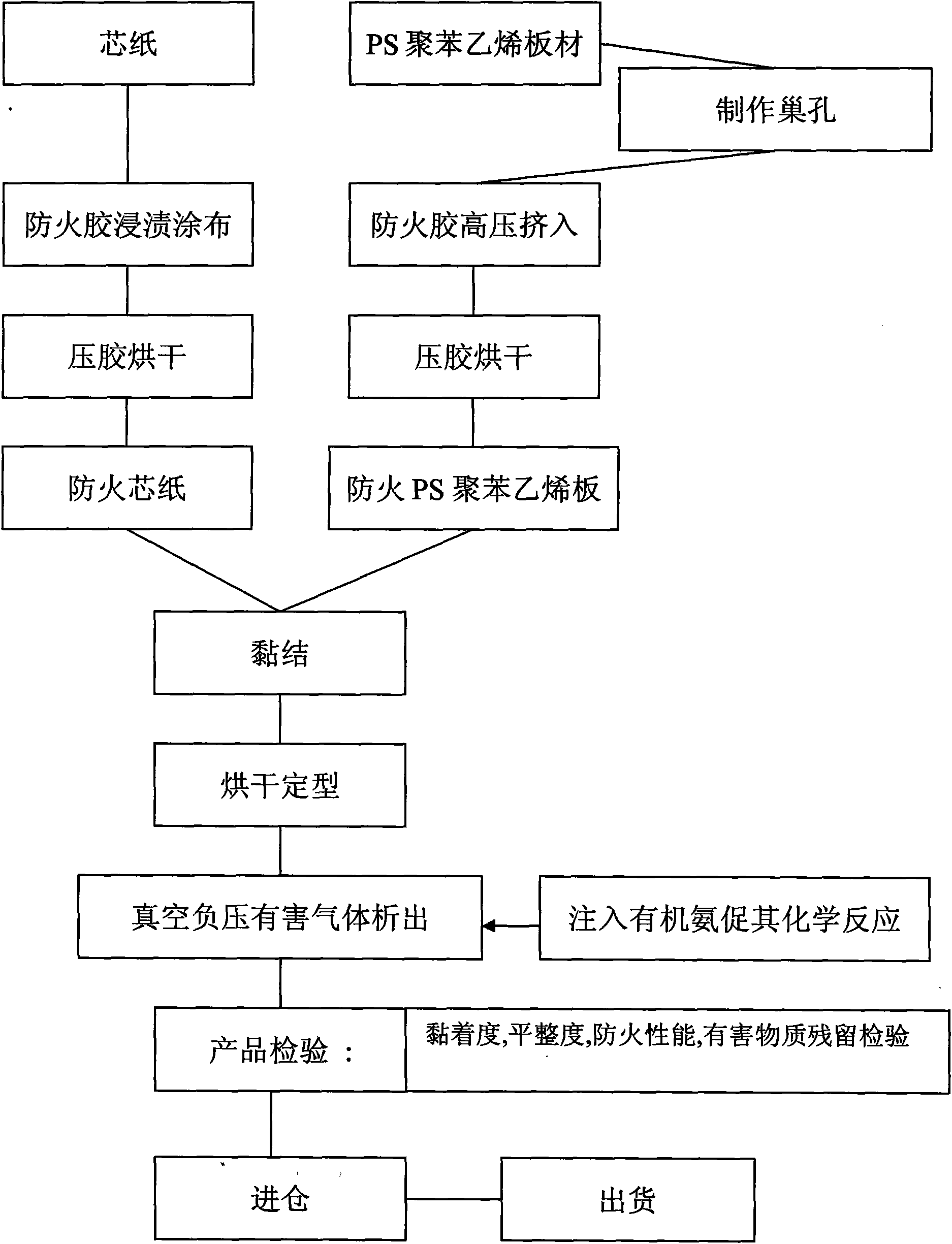

[0017] Depend on figure 1 It can be seen that the production and preparation process of the fireproof board of the present invention includes: preparation of the fireproof core paper and processing of the polystyrene board, and then pasting the fireproof core paper on both sides of the treated polystyrene board, pressing dry, and setting the shape , carry out negative pressure chemical reaction aldehyde removal treatment on the fireproof board, and then carry out the inspection of product adhesion, flatness, fire resistance, and residual formaldehyde harmful substances, and then put it into the warehouse for storage. After that, it is provisioned to users on demand.

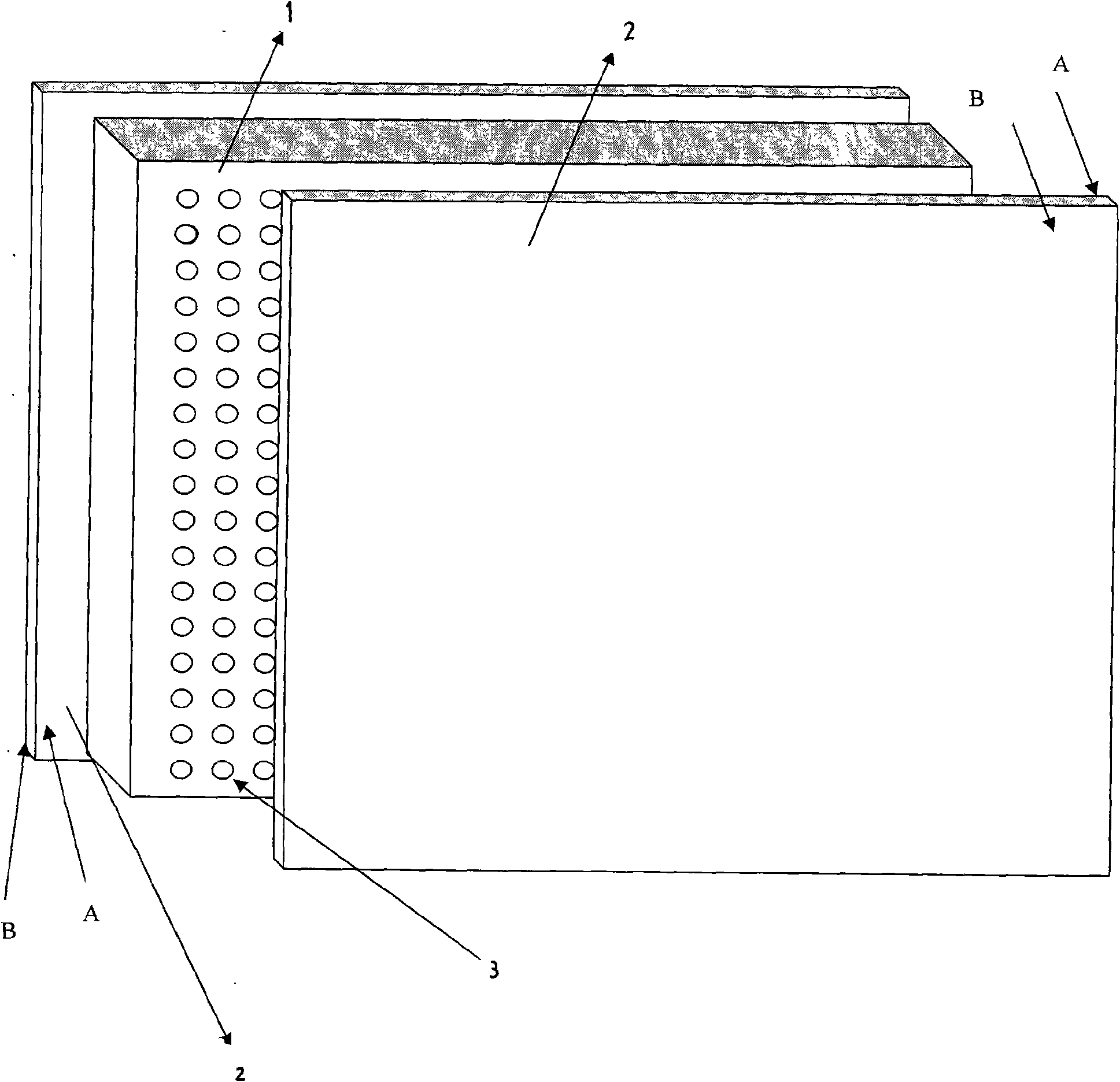

[0018] The specific structure of the fireproof board of the present invention is as follows: figure 2 As shown, the fireproof board of the present invention is pasted with fireproof core paper on the upper and lower two ends of the modified flame-retardant polystyrene board 1 . The contact surface between the ...

Embodiment 2

[0021] The preparation of the fireproof board has the following steps: 1. Make high-efficiency fireproof glue; 2. Make honeycomb dense cells on the polystyrene board (such as figure 2 (shown) the residue in the aperture must be cleaned, so that the high-efficiency fireproof glue can be squeezed in smoothly and reach the standard content; 3. Use high pressure to squeeze the high-efficiency fireproof glue into the dense nest holes on the polystyrene board; 4. Use high-efficiency fireproof glue to impregnate the core paper, dry and set it to make fireproof core paper, and set aside; 5. Use high-efficiency fireproof glue to seal the fireproof core paper figure 2 The shown fireproof core paper A side) is pasted on both sides of the polystyrene board that has been treated with fireproofing; 6. The surface of the fireproof board (such as figure 2 Surface B of the fireproof core paper shown) is coated with waterproof hardening glue; 7. Carry out pressure drying and shaping; 8. Perf...

Embodiment 3

[0025] The preparation steps of the high-efficiency fireproof adhesive are as follows: firstly, put the melamine resin base material into the reaction kettle, heat, stir, and raise the temperature to 86.5 degrees Celsius, add the phosphorus nitrogen flame retardant resin base material, keep the heat for 90 minutes, and vacuum the temperature to 86.5 degrees Celsius. Drop to 70 degrees Celsius, start cooling, add 5% smoke suppressant and 5% foaming agent at 55 degrees Celsius, add carbohydrates and soluble starch at 50 degrees Celsius, continue stirring to 35 degrees, add inorganic powder and pass through the colloid mill. into high-efficiency fireproof glue, and then discharged.

[0026] Preparation of fireproof core paper: impregnate the core paper with high-efficiency fireproof glue, and dry it at 60 degrees Celsius for 45 minutes to set it up for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com