Fire resistant viscose acetal fibre spinning solution and preparation method thereof

A technology of viscose fiber and flame-retardant viscose, which is applied in the field of flame-retardant viscose fiber spinning solution and its preparation, and can solve the problems of unrealized industrial production of flame-retardant viscose fiber, adverse effects on fiber physical and mechanical properties, and stable dispersion low cost, good dispersibility and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

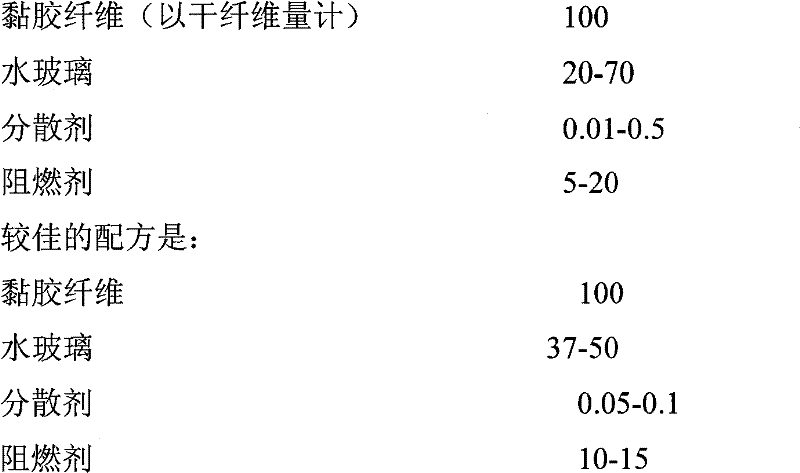

Method used

Image

Examples

example 1

[0019] Dosage as follows: viscose fiber 100g (calculated as dry cellulose), flame retardant: tris (2-butoxyethyl) phosphate (TBEP) 10g, water glass containing 30% silica and a modulus of 3.18 50g, sodium alginate dispersant 0.05g;

[0020] Add sodium alginate to water glass and mix evenly, then add TBEP to the above water glass solution and mix evenly; vacuumize, let stand for 24 hours, and debubble

[0021] Add the above-mentioned flame retardant solution to the viscose fiber stock solution, vacuumize and stand still for 24 hours to remove air bubbles to obtain a flame-retardant viscose fiber spinning solution.

[0022] The flame-retardant viscose fiber spinning solution is spun into the coagulation solution, and kept at a temperature of 60°C for 30 minutes, and the flame-retardant viscose fiber filaments are post-treated according to the traditional spinning process.

[0023] According to GB / T 5454-1997 "Oxygen Index Method for Combustion Behavior Test of Textiles" and "Det...

example 2

[0025] Dosage as follows: viscose fiber 100g (calculated as dry cellulose), flame retardant: TBEP 15g; 42g of water glass containing 35% silica and a modulus of 1.6, 0.08g of hydroxyethyl cellulose dispersant;

[0026] Prepare flame-retardant viscose fiber spinning solution according to the method of Example 1.

[0027] Spinning and aftertreatment by the method for embodiment one again.

[0028] According to the method of Example 1, the limiting oxygen index (LOI) value of the flame-retardant viscose fiber is 32.8, and the vertical burning velocity is less than 0.003m / s.

example 3

[0030] Dose as follows: viscose fiber 100g (calculated as dry cellulose), flame retardant: TBEP12g, 45g of water glass containing 30% silica and a modulus of 2.5; carboxymethylcellulose dispersant 0.08g;

[0031] Prepare flame-retardant viscose fiber spinning solution according to the method of Example 1.

[0032] Spinning and aftertreatment by the method for embodiment one again.

[0033] According to the method of Example 1, the limiting oxygen index (LOI) value of the flame-retardant viscose fiber is 32.2, and the vertical burning velocity is <0.003m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com