Method for increasing yield of SiC nano fiber by applying boric acid

A nanofiber and boric acid application technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as low yield and unapplied boric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

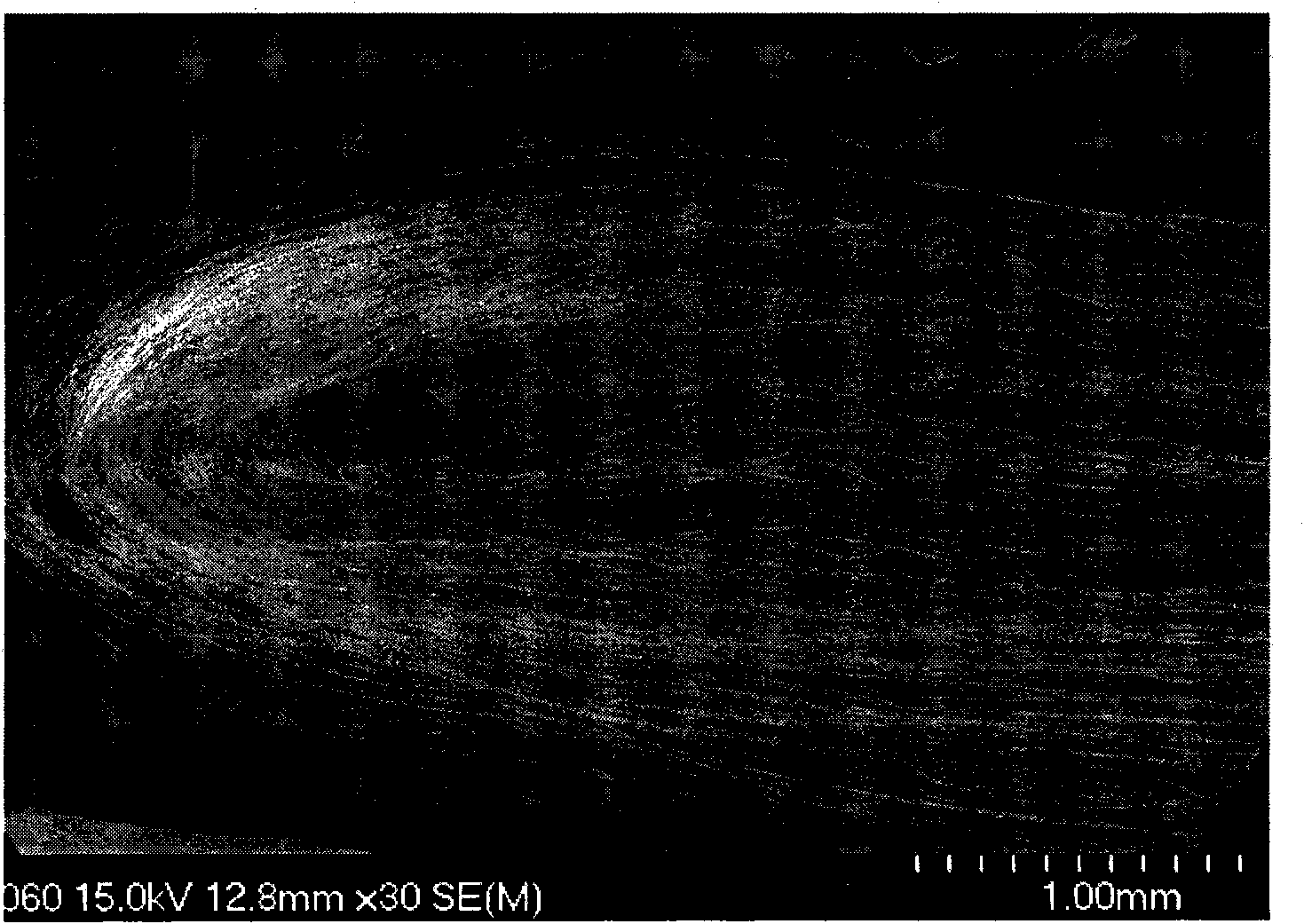

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: The method of using boric acid to increase the yield of SiC nanofibers in this embodiment is carried out according to the following steps: 1. The ratio of sucrose and silica sol is 4: 1 according to the ratio of carbon moles in sucrose to silicon moles in silica sol Mix the proportion of boric acid, and then add boric acid to the mixed solution of sucrose and silica sol, so that the mass fraction of boric acid in the mixed liquid is 0.5% to 5%, then stir at a speed of 600 to 1000r / min for 90 to 240min, and then Dry at 80-120°C for 4-8 hours to obtain xerogels; 2. Put the xerogels obtained in step 1 into a tube furnace, feed nitrogen and make the nitrogen flow 0.8-1.5L / min, Raise the temperature at a rate of 10°C / min, and keep it at 900°C for 1 hour to obtain gel powder; 3. Use a planetary ball mill to mill the gel powder at a speed of 200r / min for 2 to 4 hours, and dissolve absolute ethanol According to the ratio of adding 2mL ethanol per gram of ball-mill...

specific Embodiment approach 2

[0016] Embodiment 2: The difference between this embodiment and Embodiment 1 is: in step 1, boric acid is added to the mixture of sucrose and silica sol, so that the mass fraction of boric acid is 1-4%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 is: in step 1, boric acid is added to the mixture of sucrose and silica sol, so that the mass fraction of boric acid is 2-3%. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com