Methods and apparatus for idle time reduction in a production facility

A technology of production line and equipment, applied in the field of manufacturing automation system for moving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In general, the present invention relates to manufacturing automation systems and methods for moving material on a production line. The item can be one or more WIP items that make up a single lot.

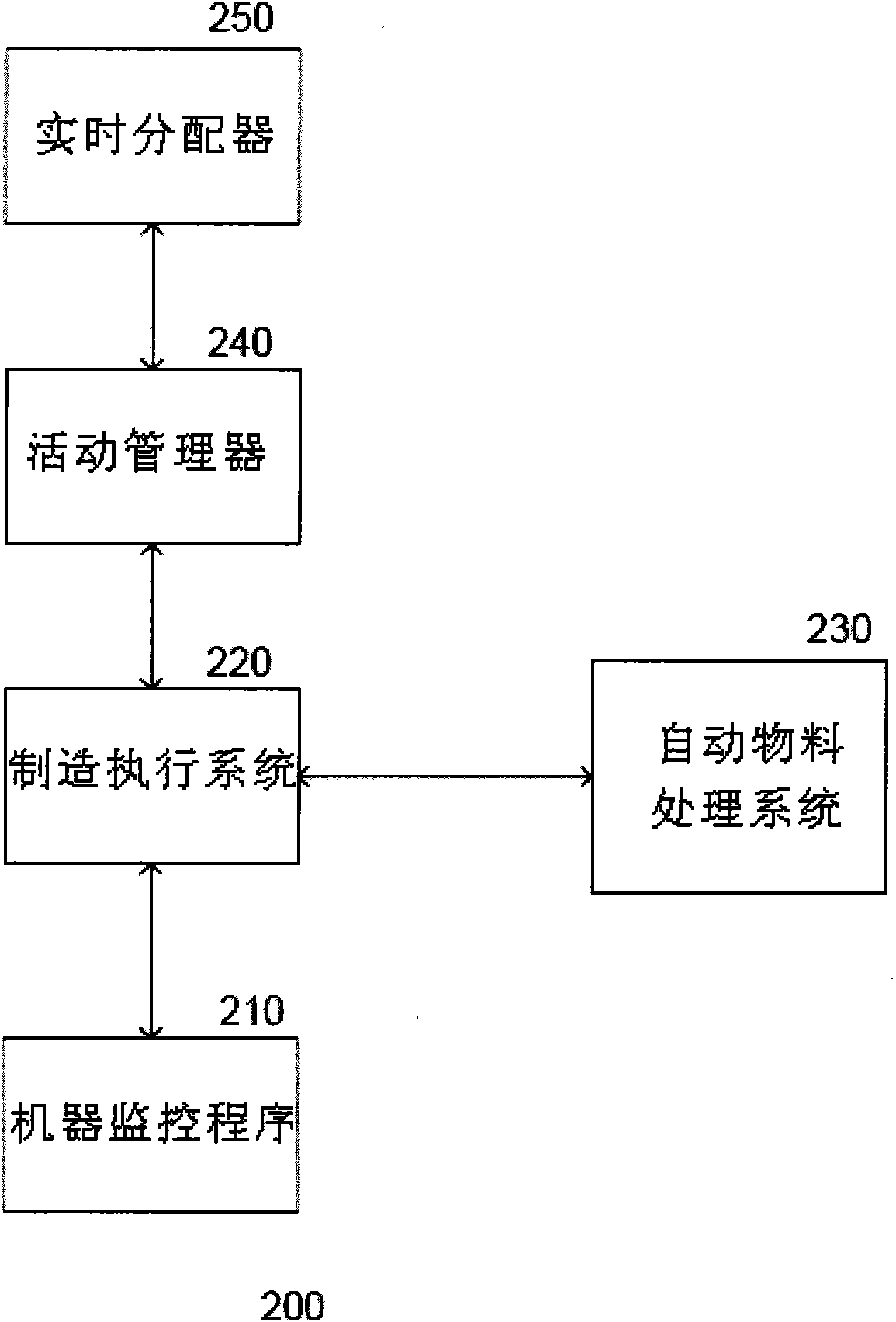

[0022] figure 2 A manufacturing automation system 200 is shown that may be used to control the operation of a production line. Such as figure 2 As shown, the manufacturing automation system 200 includes at least one machine supervisory program (MSP) 210 that monitors the status of process equipment associated therewith and acts as a communication interface with processing equipment associated therewith. The MSP is in duplex communication with Manufacturing Execution System (MES) 220 . The Manufacturing Execution System (MES) 220 tracks all execution or operations on the production line. The MES can also perform line-related functions such as tracking carrier locations and equipment status, performing lot booking and putting lots on hold.

[0023] In addition to MSP 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com